Squeeze riveter

A technology of riveting machine and riveting head, which is applied in the field of plate riveting, can solve the problems of cumbersome and inconvenient operation and low processing efficiency, and achieve the effect of convenient and fast operation and improved processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

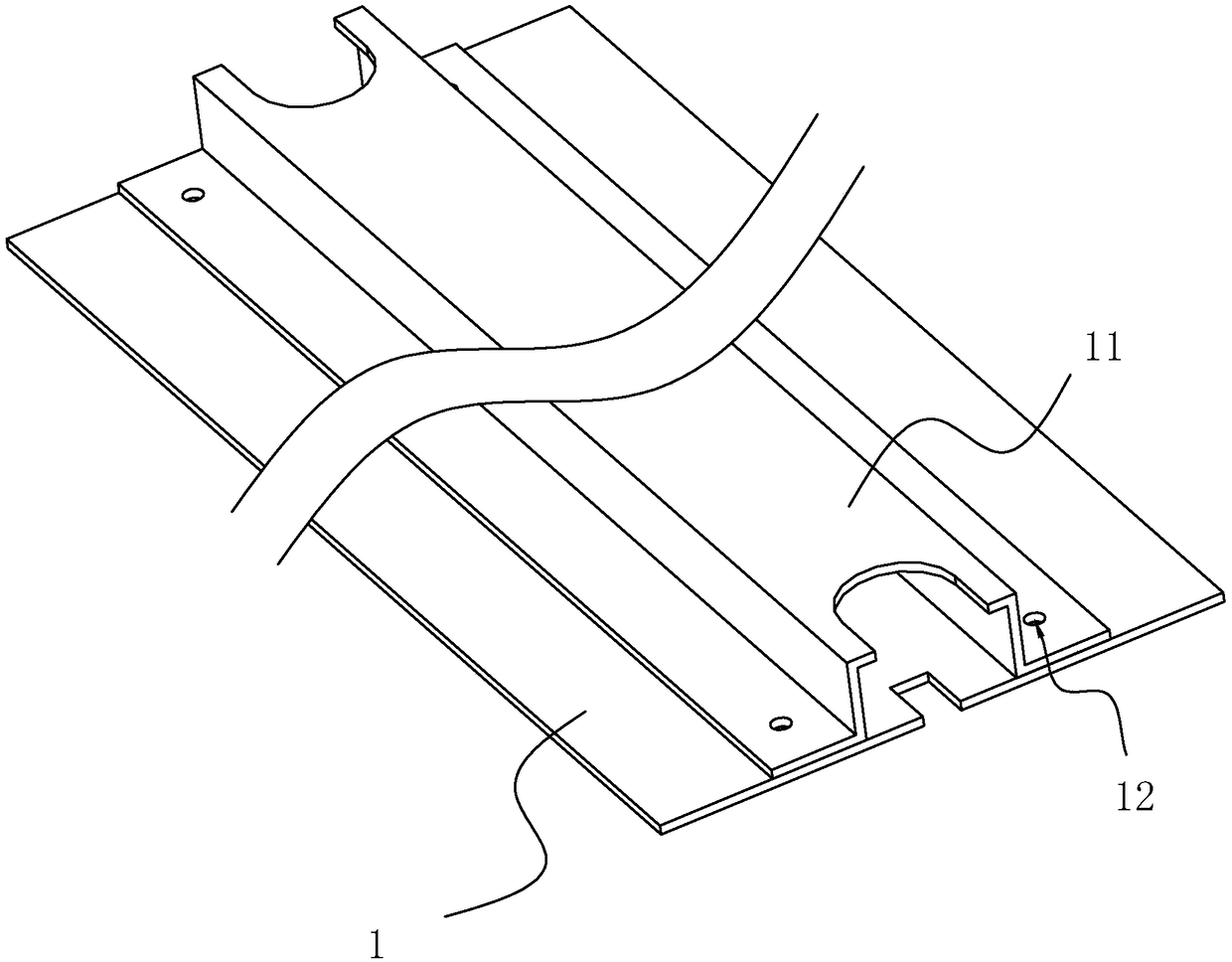

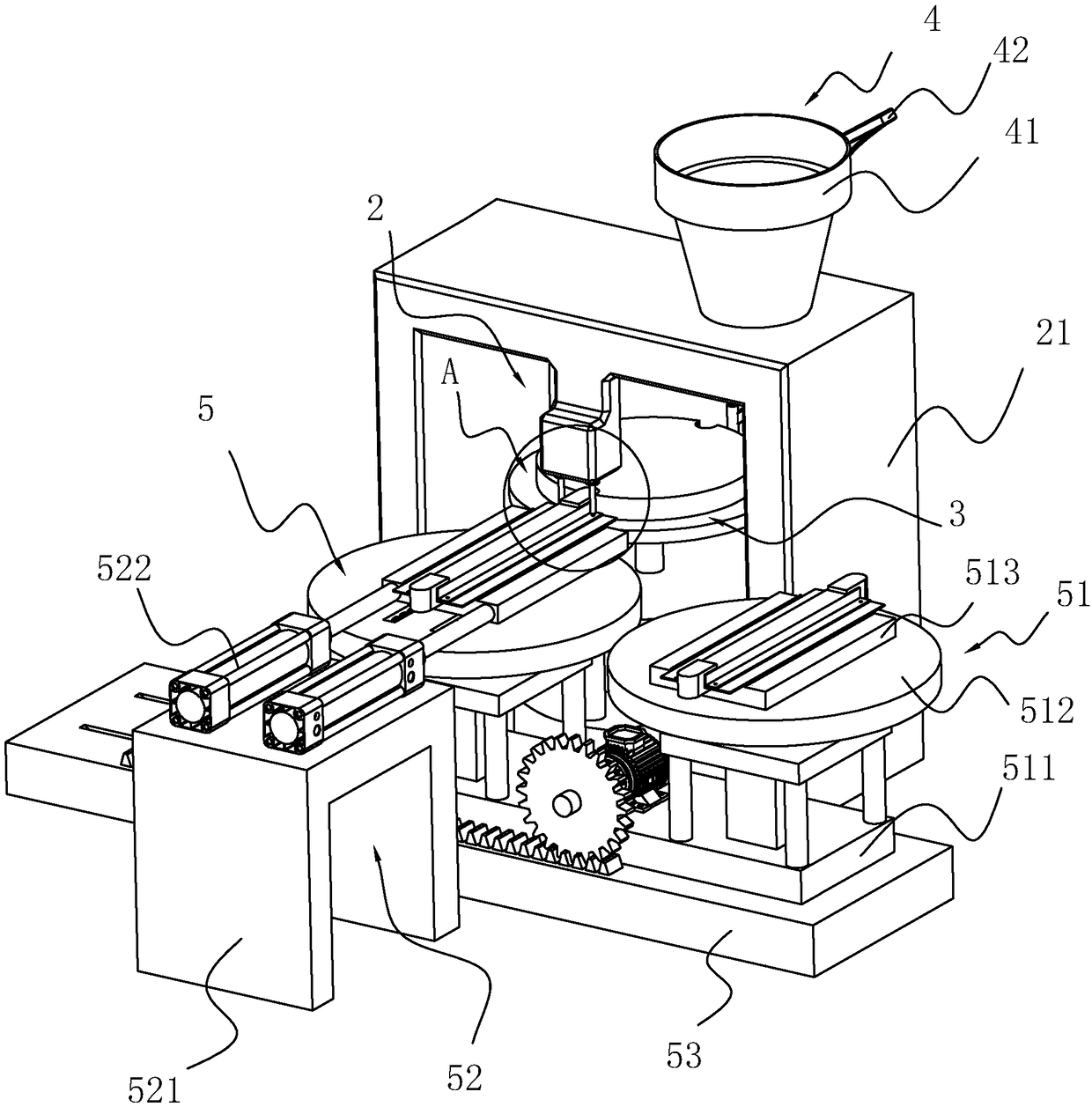

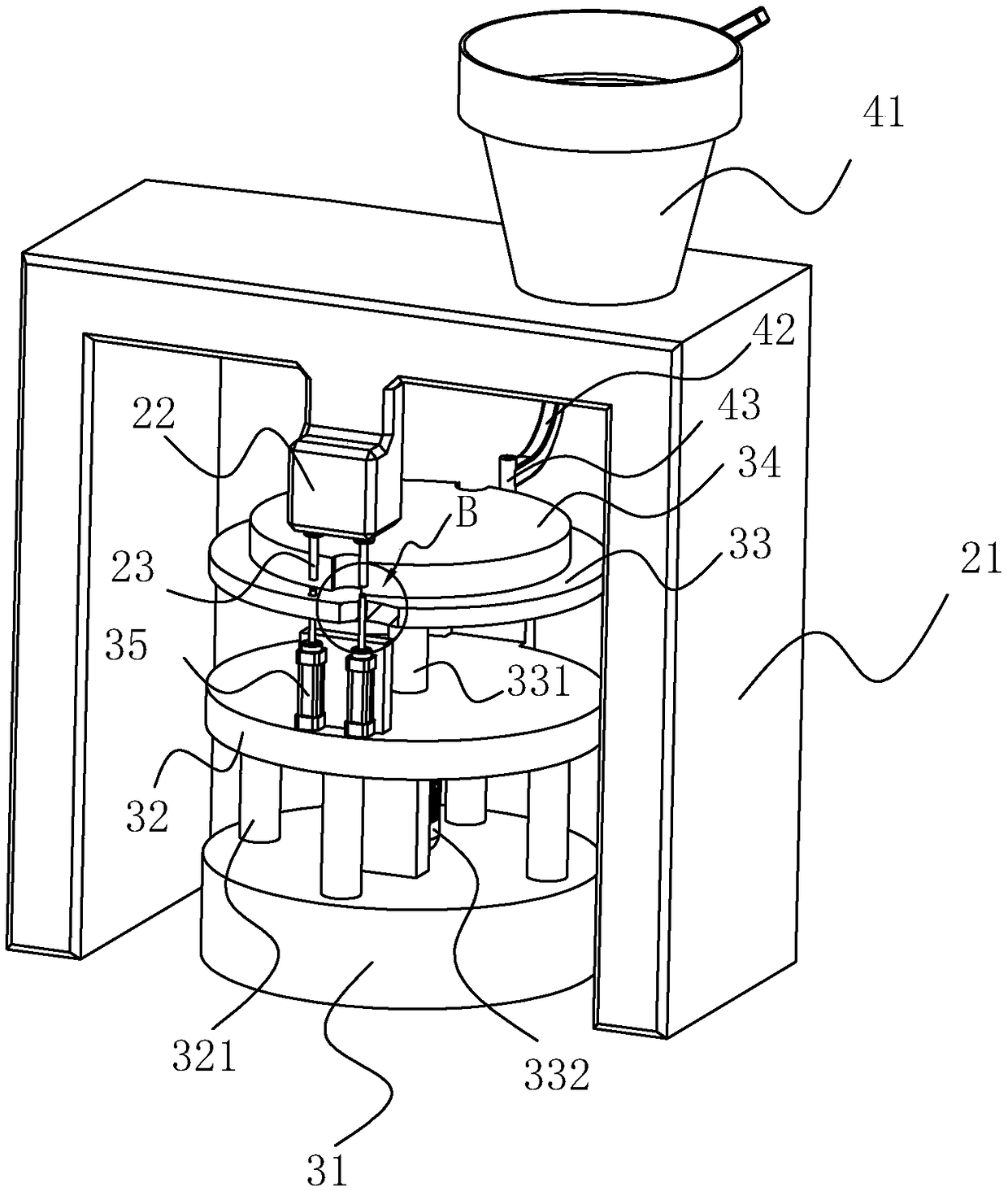

[0046] Embodiment: a kind of pressure riveting machine, is used for carrying out pressure riveting to top plate 11 and bottom plate 1, see attached figure 1 , including a riveting mechanism 2, a rivet rotating mechanism 3 arranged at the bottom of the riveting mechanism 2, a nailing mechanism 4 for conveying rivets into the rivet rotating mechanism 3, and a riveting mechanism arranged on one side of the riveting mechanism 2 for Plate riveting device 5 for rotating and riveting; the plate riveting device 5 includes a plate rotating mechanism 51 arranged on one side of the riveting mechanism 2 for fixedly rotating the plate, and a plate rotating mechanism 51 arranged on the other side of the plate rotating mechanism 51 relative to the riveting mechanism 2. The sheet feeding mechanism 52 on the side is used to push the sheet into the riveting mechanism 2 and lowers it, and the support seat 53 provided at the bottom of the sheet rotating mechanism 51 is used to support the sheet ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com