Manual adjusting system for any distance between saw blades for cutting plates of different thicknesses

A manual adjustment and saw blade technology, applied in sawing machine devices, metal sawing equipment, metal processing equipment, etc., can solve the problems of reducing adjustment efficiency, complex adjustment structure, unable to achieve adjustment at any distance between saw blades, etc., to achieve adjustment efficiency High and easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

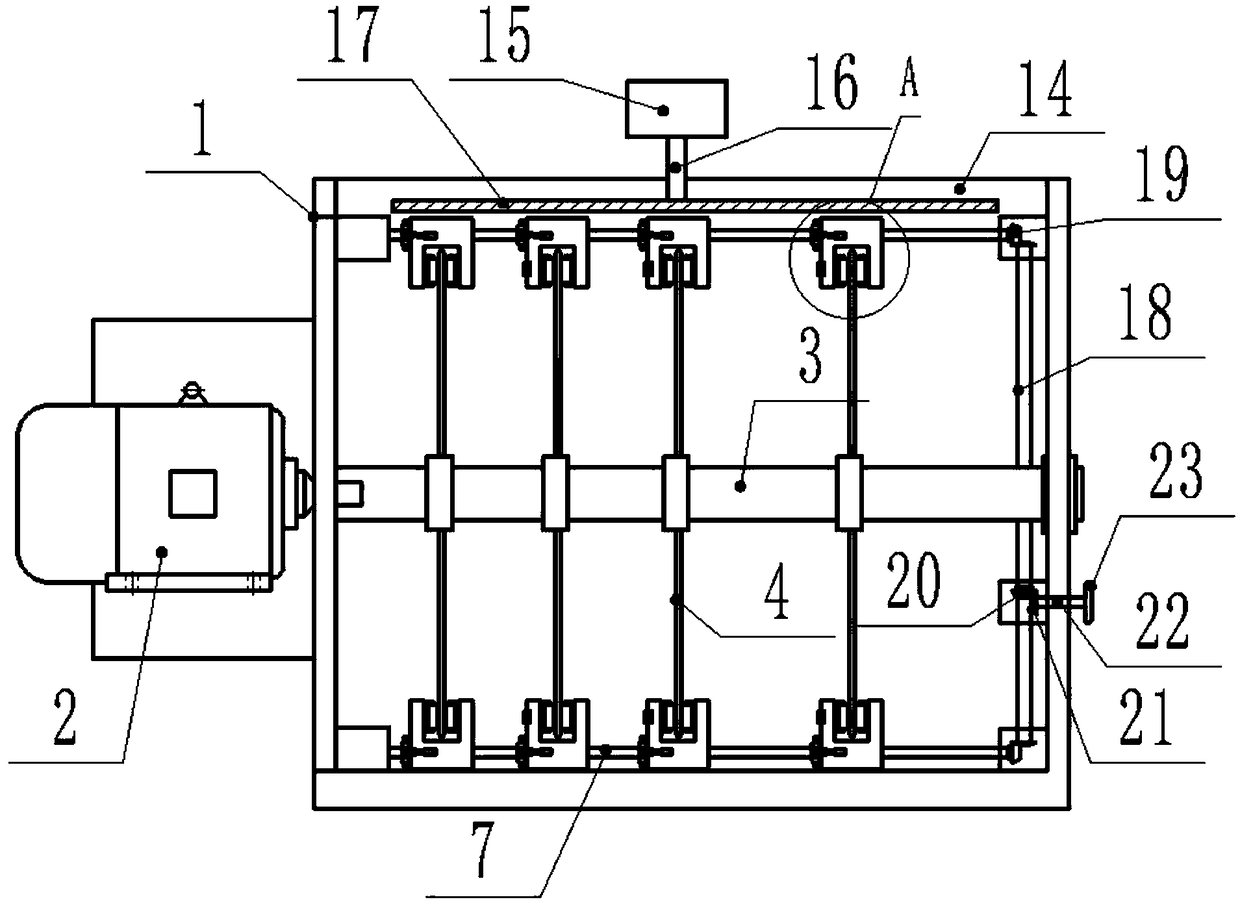

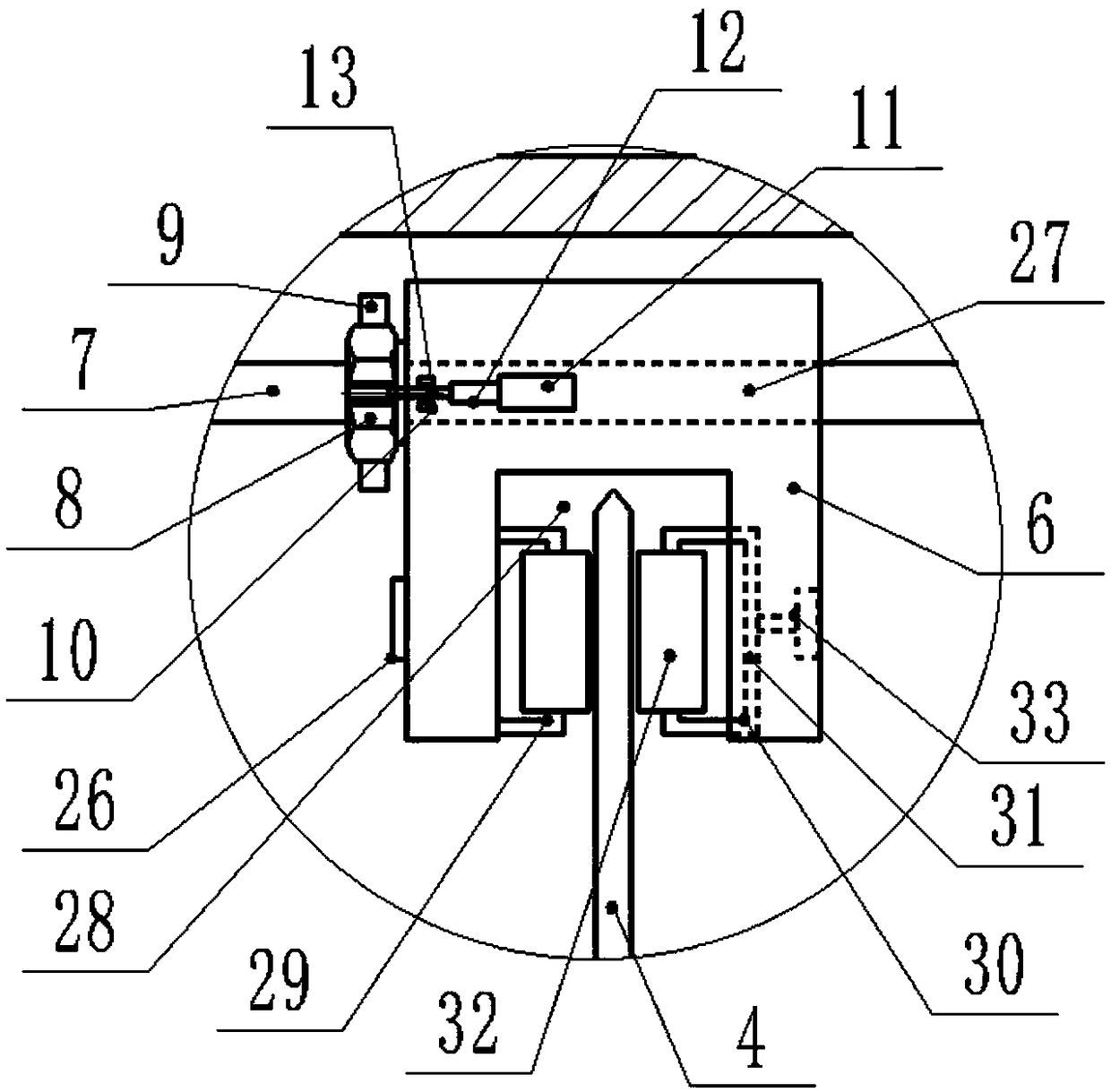

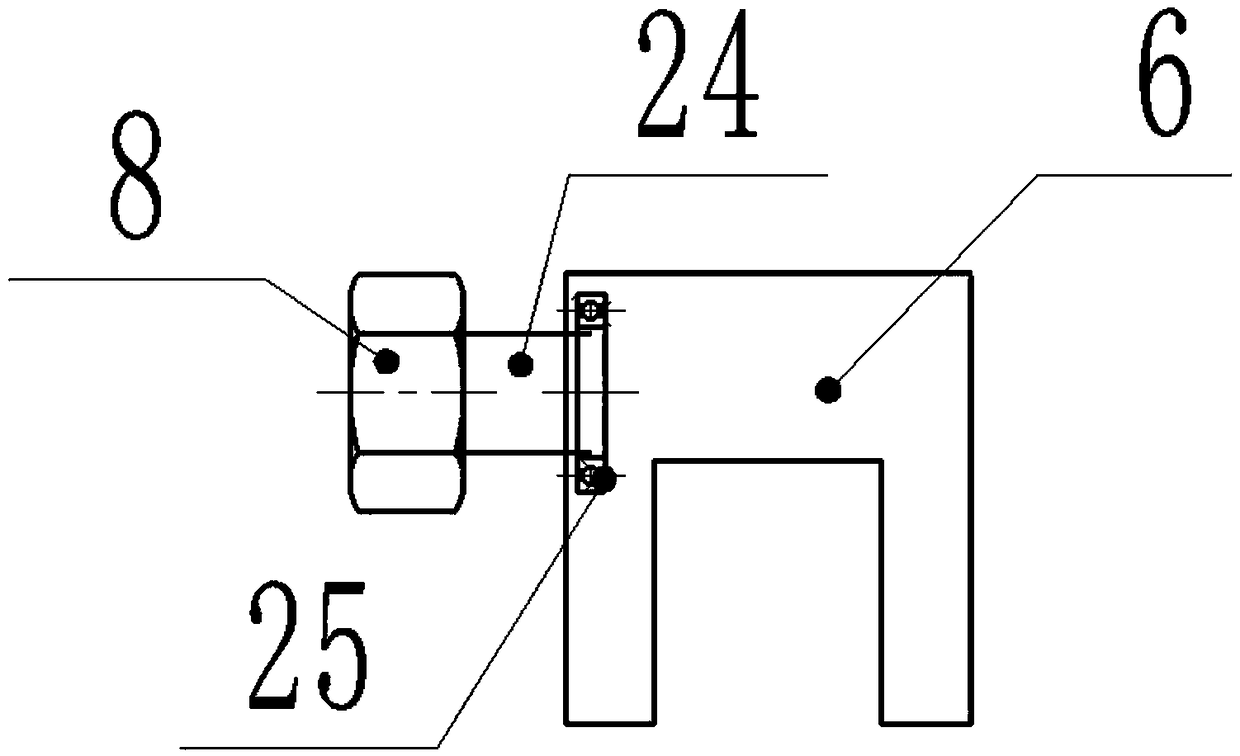

[0032] Such as Figure 1-3 As shown, the present invention 1. A manual adjustment system for saw blades with any spacing for cutting plates of different thicknesses, comprising a chainsaw support frame 1, a motor 2, a saw blade spline shaft 3 and a saw blade 4, the chainsaw support frame 1 The middle part is provided with the saw blade spline shaft 3, and the multi-blade saw blade 4 is sleeved on the saw blade spline shaft 3 through the spline sleeve 5. The spline sleeve 5 and the saw blade spline shaft 3 cooperate with each other, and the saw blade spline When the rotating shaft 3 rotates, it can synchronously drive the saw blade 4 to rotate. At the same time, after contacting the left and right movement limit of the saw blade, the saw blade 4 can move on the saw blade spline shaft 3. The motor 2 is connected to the saw blade spline One end of the key rotating shaft 3 drives the saw blade spline rotating shaft 3 and the saw blade 4 on the saw blade spline rotating shaft 3 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com