Welding method of frame type aluminum alloy body assembly

A welding method and aluminum alloy technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problem that the welding quality and dimensional accuracy of the car body cannot be guaranteed, the welding quality and dimensional accuracy are difficult to control, and the welding deformation of the car body cannot be effectively reduced And other problems, to achieve the effect of reducing size defects, improving welding efficiency and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

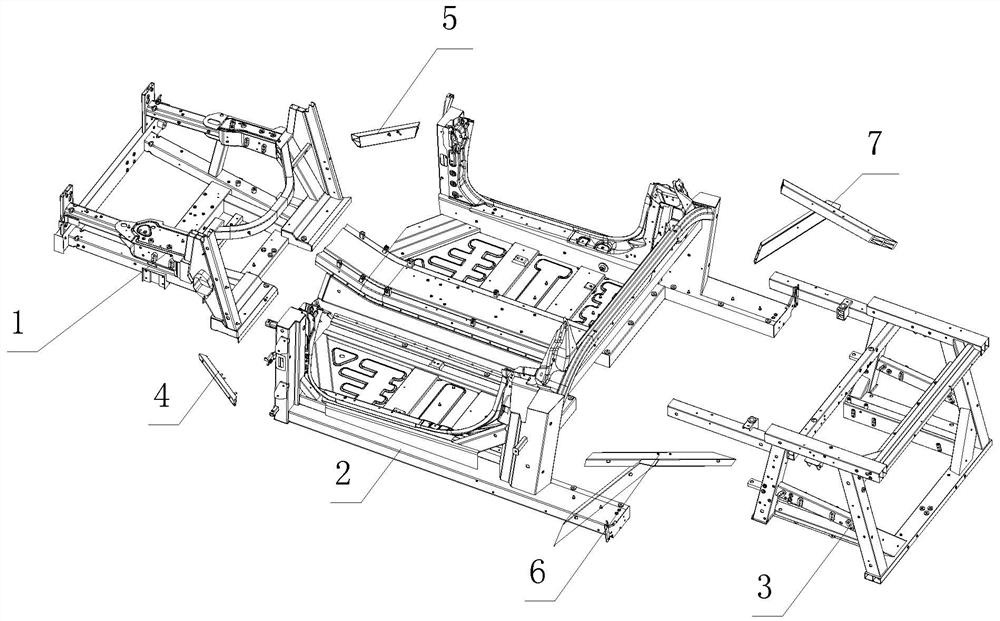

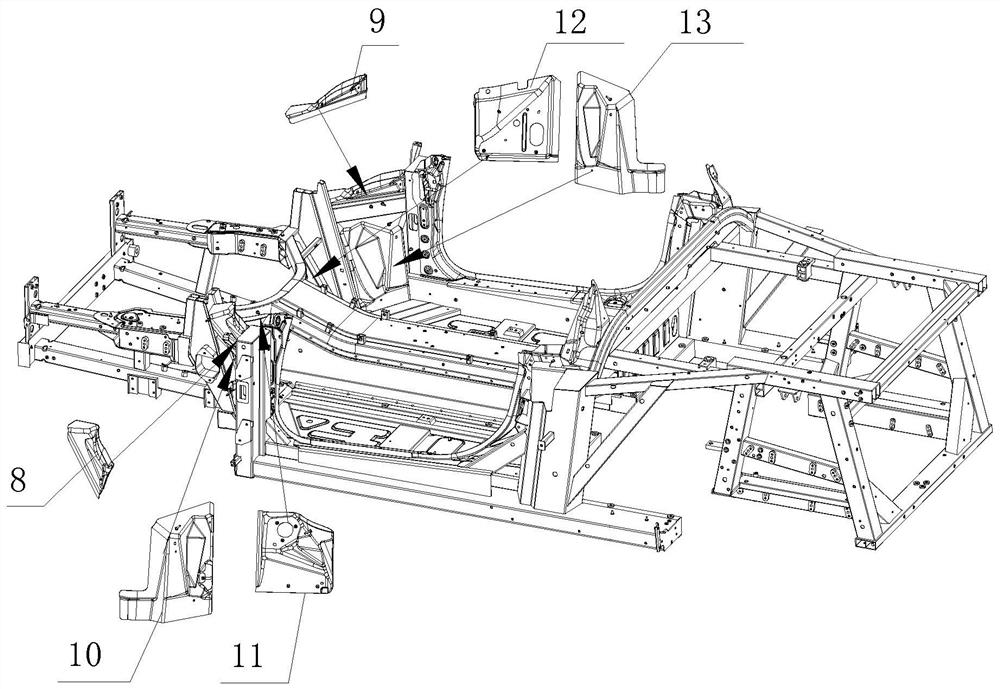

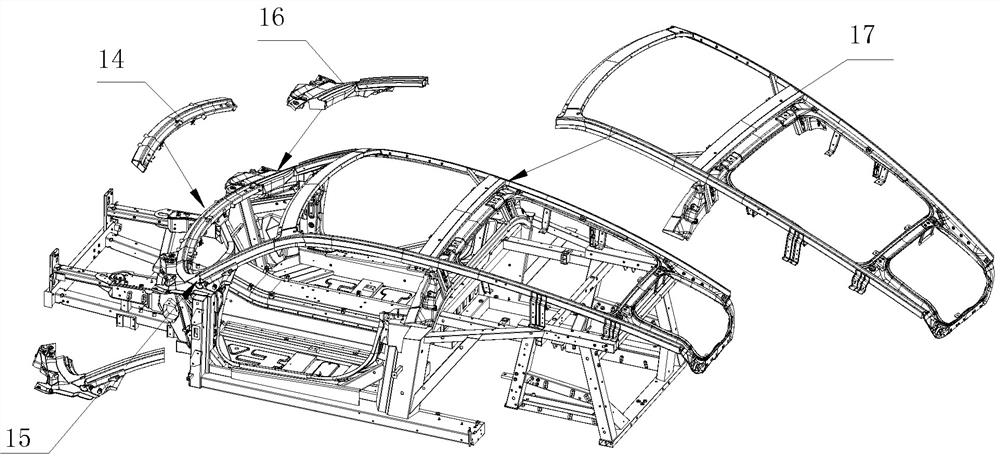

[0040] refer to Figure 1-Figure 10 , this embodiment discloses a welding method for a frame-type aluminum alloy body assembly, wherein the frame-type aluminum alloy body assembly includes a body subassembly, an air chamber assembly, an upper body assembly 17, a left hinge connecting plate 18, Right hinge connecting plate 19, dash panel assembly 21, brake pedal mounting bracket 20, left front wheel house reinforcement beam 22 and right front wheel house reinforcement beam 23, the welding method of the body assembly includes the following steps:

[0041] 1) Carry out welding of body sub-assemblies;

[0042] Among them, the body subassembly includes the underbody assembly, the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com