Moisture-proof power cabinet

A power cabinet and cabinet technology, applied in the field of power grid operation and maintenance tool storage equipment, can solve problems such as unreasonable design of dehumidification heating modules and inability to cover items, and achieve the effects of avoiding heat loss, direct moisture-proof effect, and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

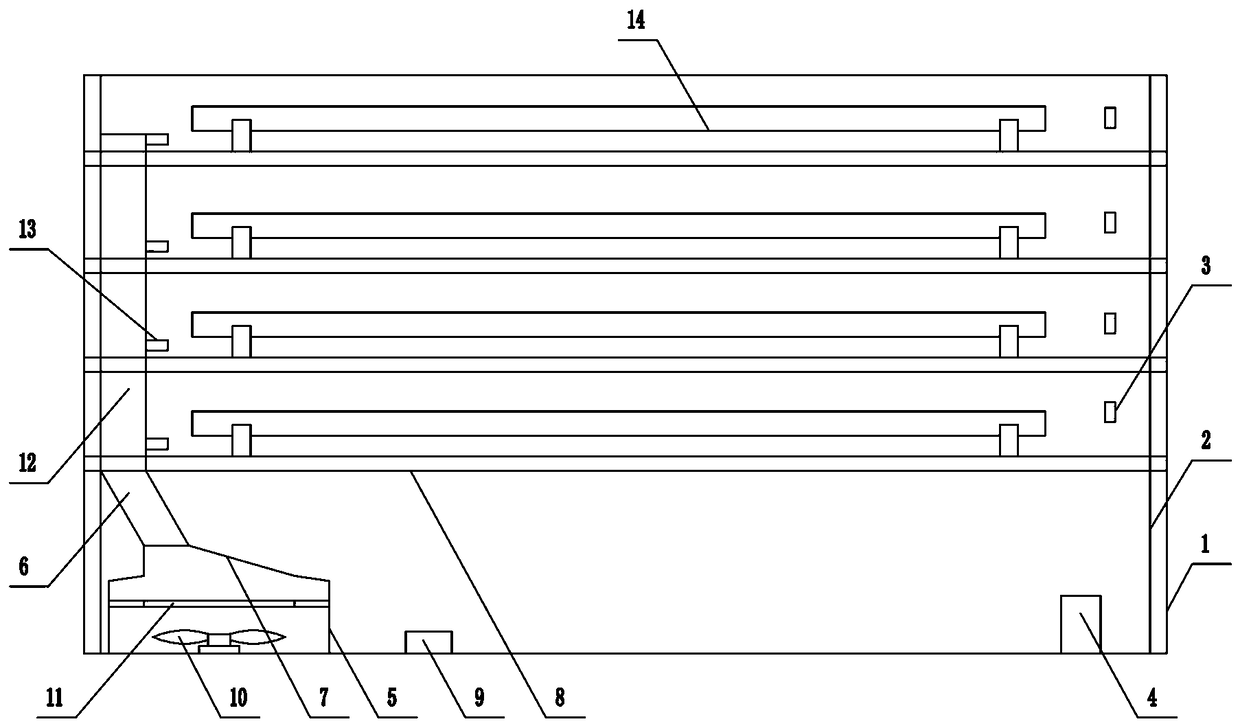

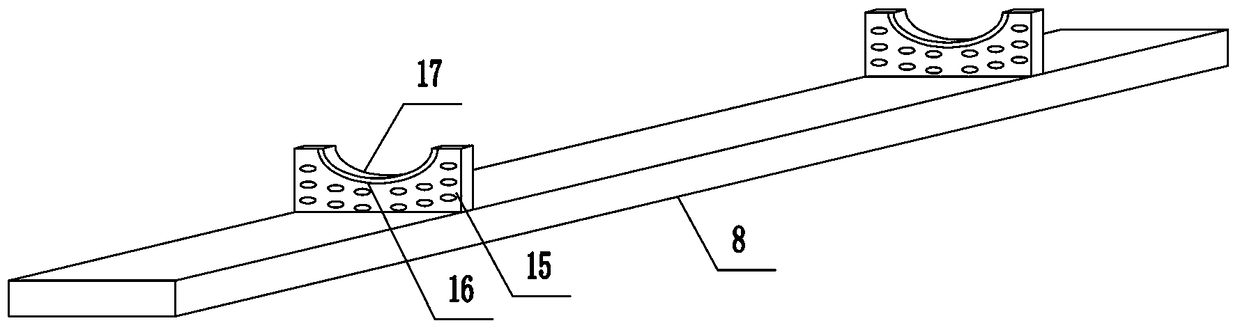

[0028] Such as figure 1 and figure 2 As shown, the present invention includes a cabinet body 1, a heat insulation layer 2 arranged on the inner wall of the cabinet body 1, and a humidity control device arranged in the cabinet body 1, and the humidity control device includes four humidity sensing modules 3 arranged in the cabinet body 1 , a central processing module 4 and a hot air generating device arranged in the hot air distribution housing 5 at the bottom of the cabinet body 1, the hot air distribution housing 5 is provided with an air inlet and an air outlet pipeline 6, and the air inlet is located at the hot air At the bottom of the distribution housing 5, the air outlet pipeline 6 communicates with the air flow channel. The hot air distribution housing 5 includes an arc-shaped top plate 7. Body 5 is internally connected;

[0029] The output ends of a plurality of humidity sensing modules 3 are electrically connected to the input ends of the central processing module 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com