Pressure maintaining and increasing hinge and welding machine thereof

A hinge and hinge technology, which is applied in the field of pressurized hinges and their welding machines, can solve the problems of high labor intensity, poor cooling effect, simultaneous locking, etc., and achieve the effect of improving welding fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

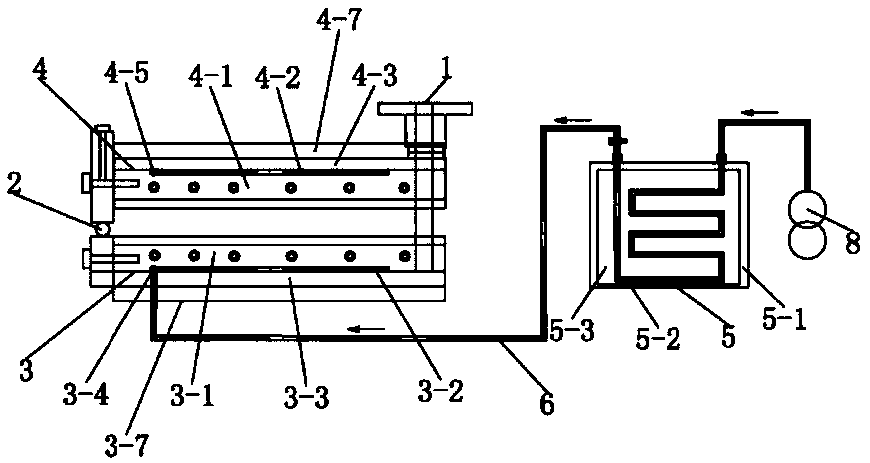

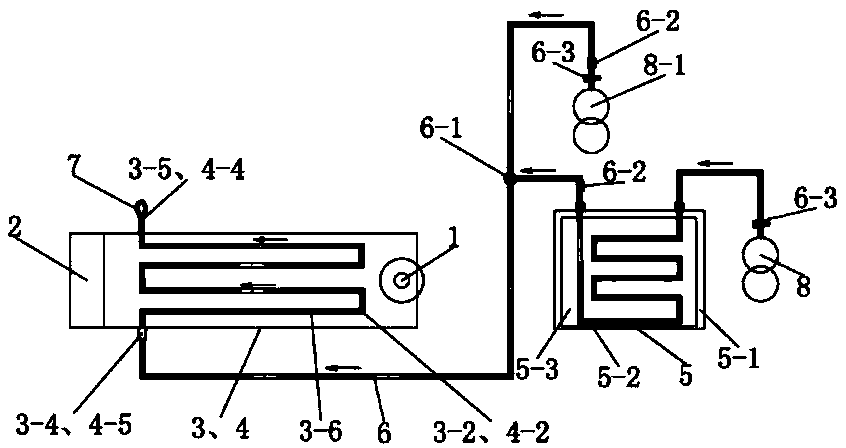

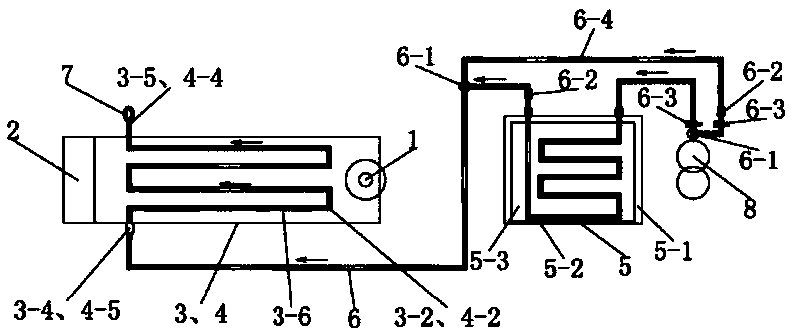

[0168] Such as Figure 1 to Figure 3 As shown, this embodiment provides a welding machine, including a lower electric heating splint 3 and an upper electric heating splint 4, the lower electric heating splint 3 is provided with a lower cold air circulation cooling channel 3-2, and the upper electric heating splint 4 is provided with The upper cold air circulation cooling passage 4-2, the lower cold air circulation cooling passage 3-2 and the upper cold air circulation cooling passage 4-2 communicate with the cold air source.

[0169] During the cooling process, the welding machine of this embodiment not only does not pollute the environment, but also greatly saves water resources, and can realize rapid cooling even if there is no water source.

[0170] Various improvements of this embodiment are described in detail below.

[0171] Such as Figure 1 to Figure 2 As shown, the cold air source is an air refrigeration device 5 .

[0172] The air refrigeration device 5 includes a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com