Regulation and control device, substrate glass production line, and regulation and control method

A technology of regulating devices and regulating parts, which is applied in glass forming, glass forming, glass manufacturing equipment, etc., and can solve problems such as unstable quality of substrate glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

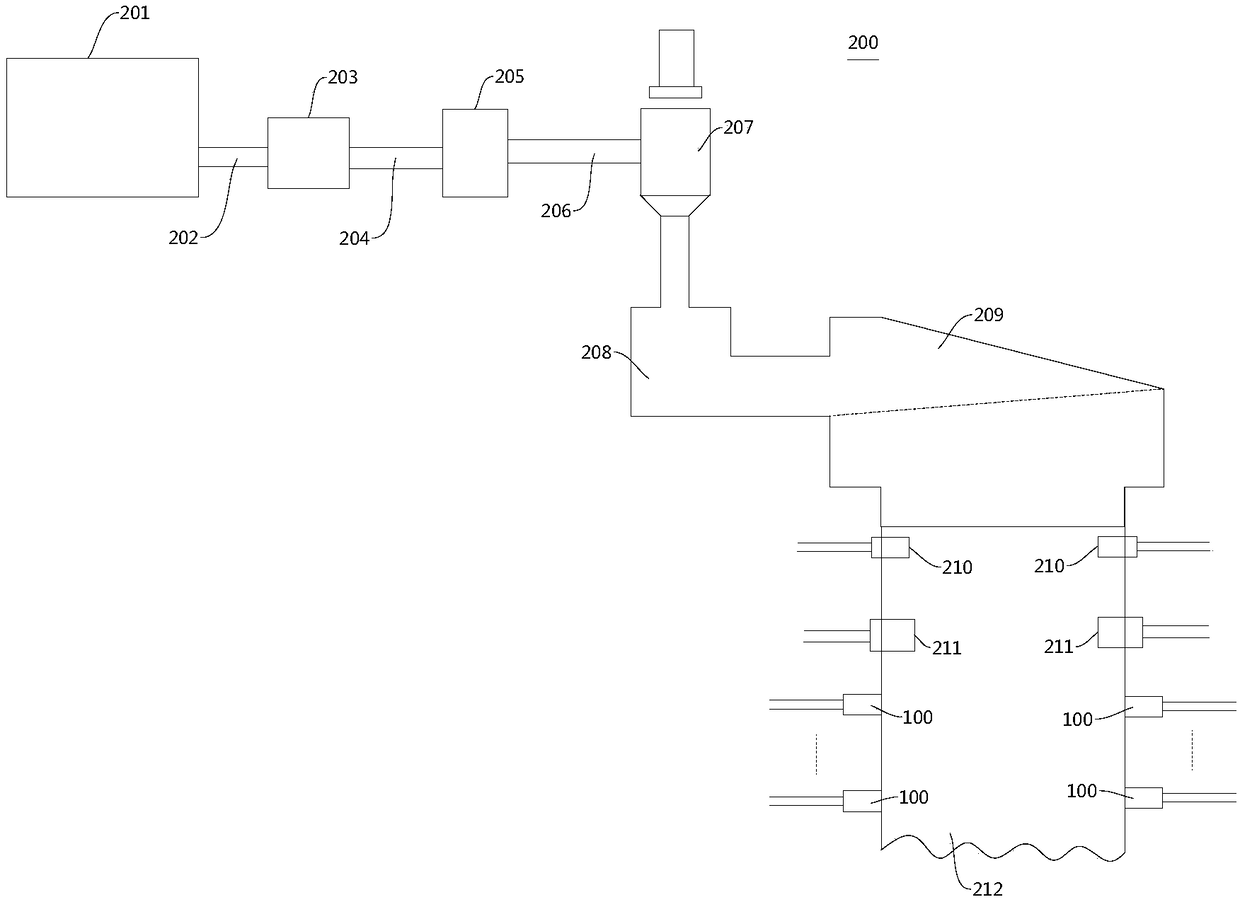

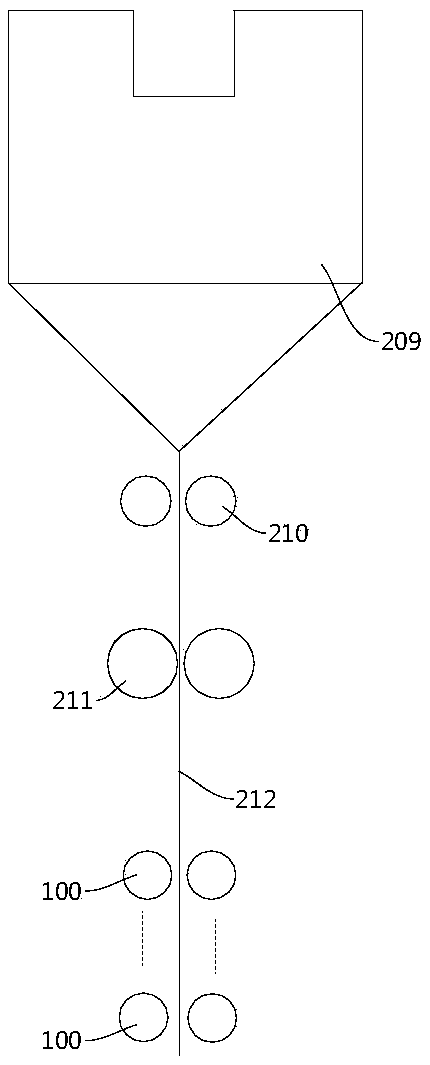

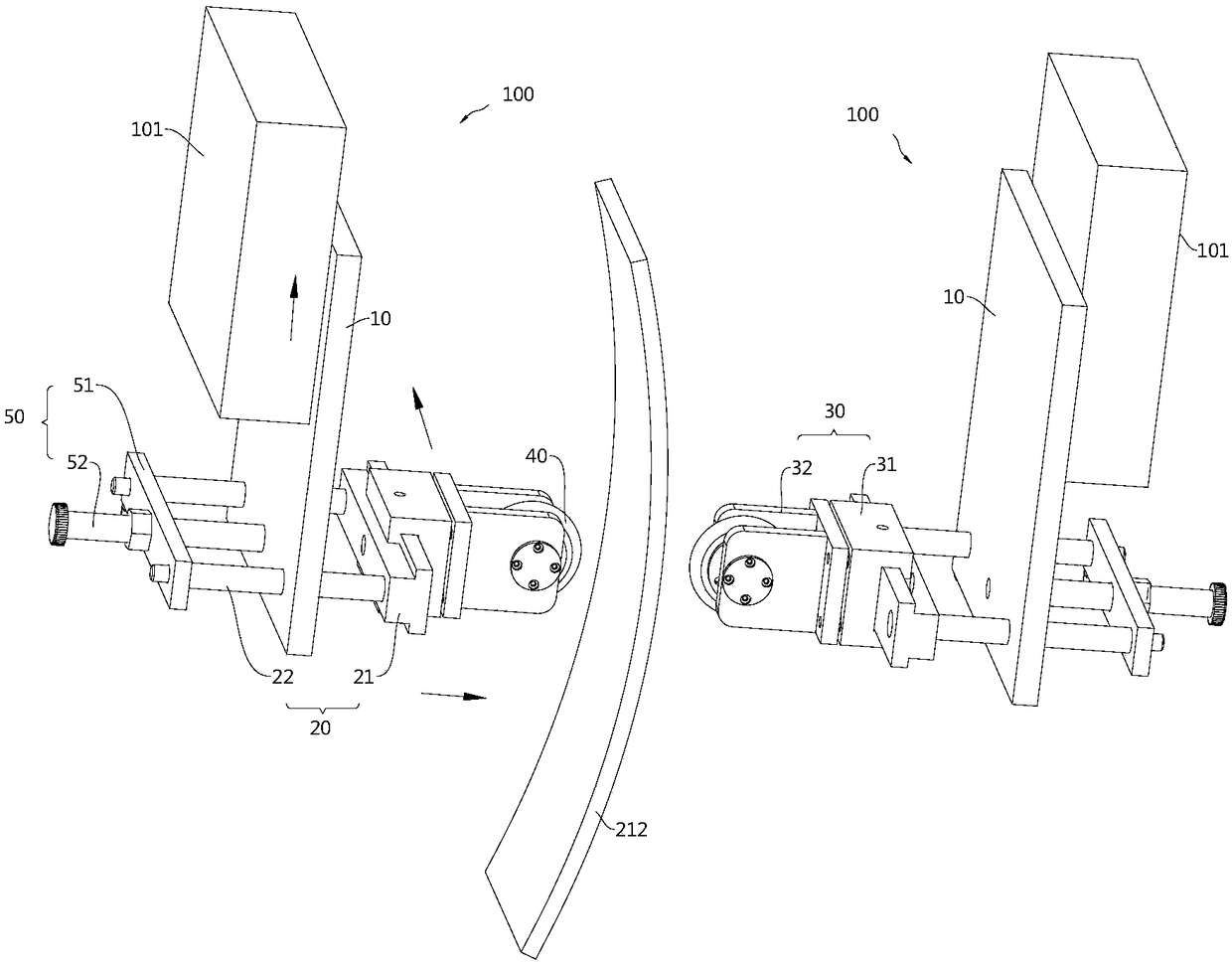

[0056] Please refer to figure 1 and figure 2 , this embodiment provides a control device 100 and a substrate glass production line 200 using the control device 100, the structure of the control device 100 is image 3 and Figure 4 shown in .

[0057] combine figure 1 and figure 2 , figure 1 The substrate glass production line 200 shown in includes a melting furnace 201, a first connecting pipe 202, a refining device 203, a second connecting pipe 204, a stirring device 205, a connecting device 206, a conveying device 207, a connecting device 208, an overflow device 209 , edge pulling device 210 , traction mechanism 211 and regulating device 100 .

[0058] In this embodiment, the substrate glass is first melted into molten glass in a high-temperature melting furnace 201 according to a certain proportion of glass ingredients, and then made into a glass ribbon 212 through a forming process system, and then drawn into a substrate by a traction mechanism 211 Glass.

[0059...

Embodiment 2

[0102] This embodiment provides a control method, which uses the above-mentioned control device 100, and the method includes:

[0103] At least one of the first regulating member 10 , the second regulating member 20 and the third regulating member 30 is controlled to make the guide wheel 40 contact the position to be contacted with the glass ribbon 212 and guide the glass ribbon 212 to flow.

[0104]For the structure of the regulating device 100, reference may be made to Embodiment 1.

[0105] Please refer to Figure 8 , Figure 8 The illustrated substrate glass 300 is subject to natural warping. Therefore, the guide wheels 40 positioned on both sides of the glass ribbon 212 do not contact the glass ribbon 212, only the edge pulling device 210 and the traction mechanism 211 are in contact with the glass ribbon 212, so that the glass ribbon 212 is in contact with the glass ribbon 212. Figure 9 state in .

[0106] Please refer to Figure 10 , Figure 10 The substrate glas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com