Knitting device and method of computerized flat knitting machine

A computerized flat knitting and needle selection technology, which is applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of easy strike-pin, inconvenient installation, large number of triangular parts, etc., and achieves simple and reasonable design and simplified structure. , the effect of undiminished function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0047] Example.

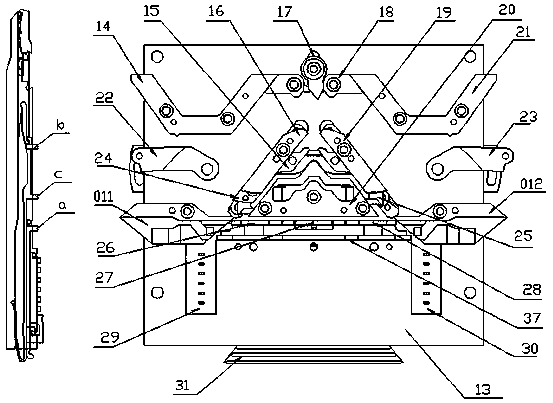

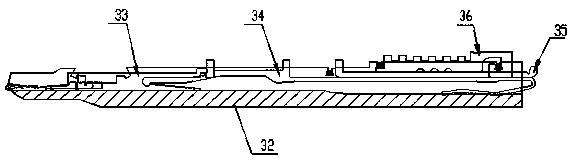

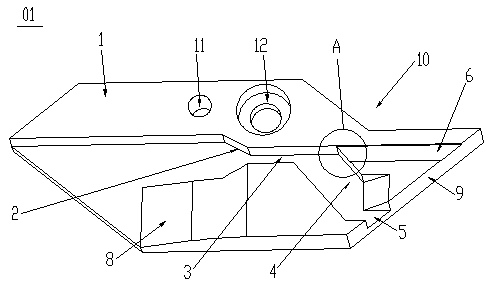

[0048] see Figure 1 to Figure 18 .

[0049] In this embodiment, a computerized flat knitting device includes a triangular bottom plate 13 and a knitting needle assembly. At least one knitting unit is arranged on the triangular bottom plate 13. The knitting unit and the knitting needle assembly cooperate with each other to weave. The knitting unit includes a left upper guard 14, a swing Triangle 17, transfer stitch triangle 18, upper right guard 21, left back stitch triangle 22, right back stitch triangle 23, left stitch triangle 16, right stitch triangle 19, left second-stage stitch triangle 24, right second-stage stitch triangle 25, weaving Triangle 15, dish mountain 20, guide mountain corner 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com