A device for adjusting the alternate amount of presser feet on a sewing machine and its control method

A sewing machine and presser foot technology, which is applied in the direction of sewing machine components, sewing equipment, cloth pressing mechanism, etc., can solve the problems of poor adjustability of presser foot alternating amount, insufficient application range, and inconvenient use, etc., and achieves wide application range and reduced Effects of noise and parts wear and improvement of productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

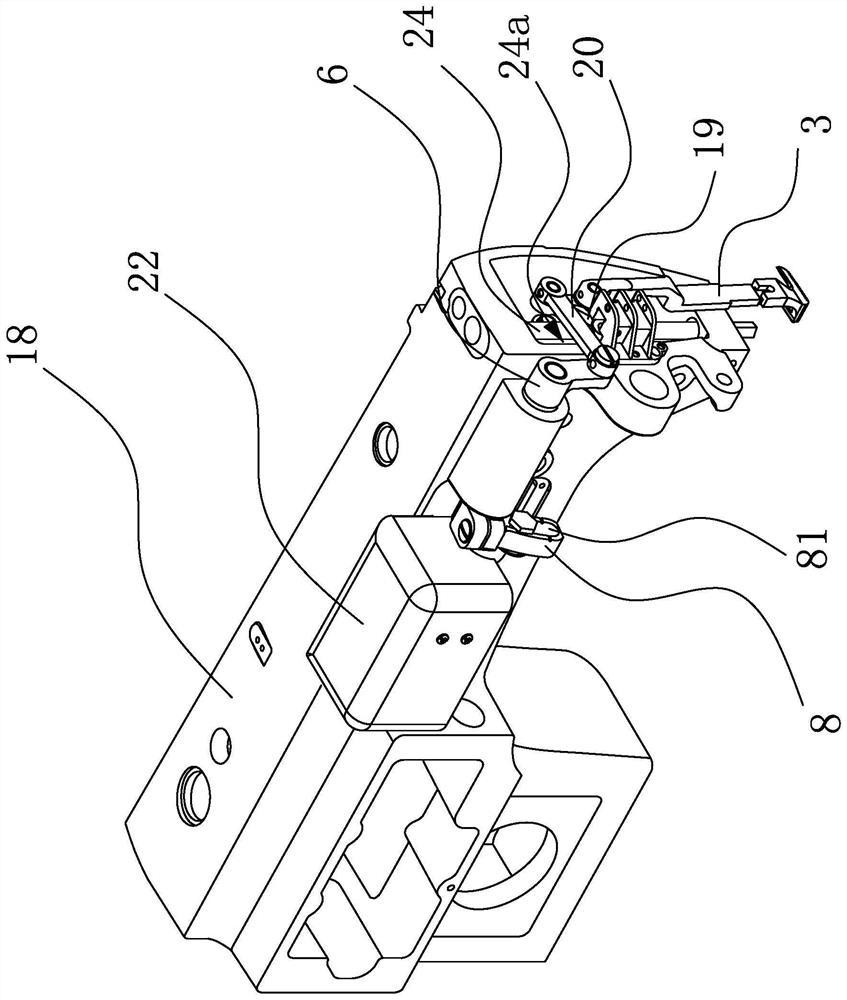

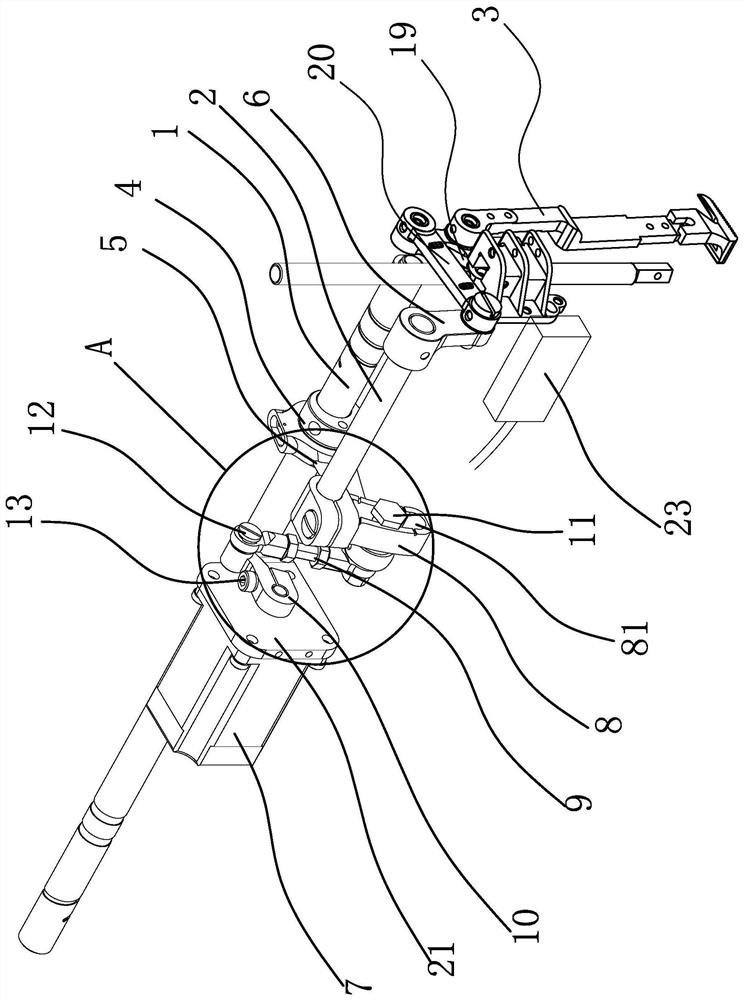

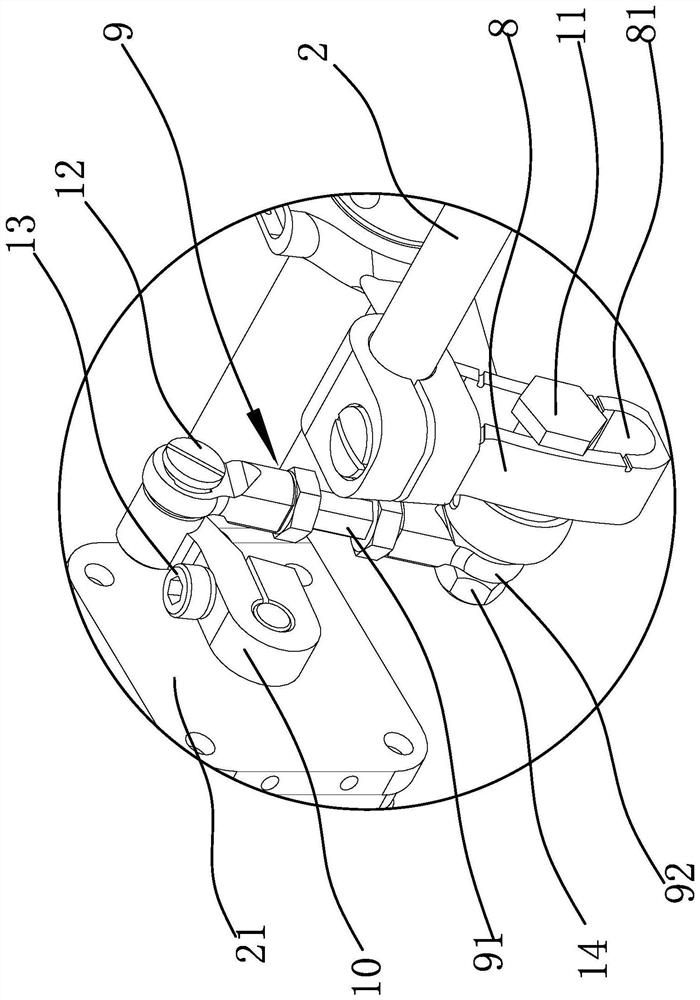

[0044] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the sewing machine includes an upper shaft 1, a presser foot lifting shaft 2 and a presser foot rod 3, the upper shaft 1 is provided with an eccentric wheel 4, and the eccentric wheel 4 is connected with the presser foot lifting shaft 2 through an eccentric connecting rod 5, and the presser foot The lifting shaft 2 is connected with the presser foot bar 3 through the presser foot lift crank 6 and can drive the presser foot bar 3 to reciprocate up and down. The device includes a stepper motor 7 and an adjustment crank 8. The stepper motor 7 drives the swing crank 10 that swings down. The swing crank 10 is connected with an adjustment link 9 that can adjust the length. One end of the adjustment link 9 is hinged with the end of the swing crank 10. The other end of the adjustment link 9 The limit screw 11 is rotatably connected; one end of the eccentric connecting rod 5 is hinged with the limit screw 11; Wa...

Embodiment 2

[0049] Such as Figure 5 As shown, the present embodiment is roughly the same as the first embodiment, the difference is that in the present embodiment, the output shaft of the stepper motor 7 is fixedly provided with a helical gear 15, and the device also includes a drive shaft 17, the drive shaft 17 The axial direction is perpendicular to the axial direction of the output shaft of the stepping motor 7, the transmission shaft 17 is fixedly provided with a helical gear 2 16, the helical gear 15 is meshed with the helical gear 2 16, and one end of the swing crank 10 is fixedly connected to the transmission shaft The end of 17; The end of adjusting link 9 is connected with the other end of swing crank 10. This facilitates the installation and layout of the entire device, and makes the structure compact and the transmission stable and reliable.

Embodiment 3

[0051] Such as Figure 6 As shown, this embodiment is substantially the same as Embodiment 1, the difference is that the adjusting link 9 in this embodiment includes two strip plates 93, and one end of the strip plate 93 has a The other end of the bar-shaped hole 93a has a mounting hole 93b, and the ends of the two bar-shaped plates 93 with the bar-shaped hole 93a fit together and are connected by adjusting bolts 94 inserted in the bar-shaped hole 93a.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com