Fabric embossing automation equipment

An automatic equipment and fabric technology, which is applied in the direction of textiles, papermaking, textile decoration, etc., can solve the problems of low embossing efficiency of cloth embossing equipment, achieve continuous embossing automatic operation, high embossing efficiency, Meet the effect of embossing in large quantities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

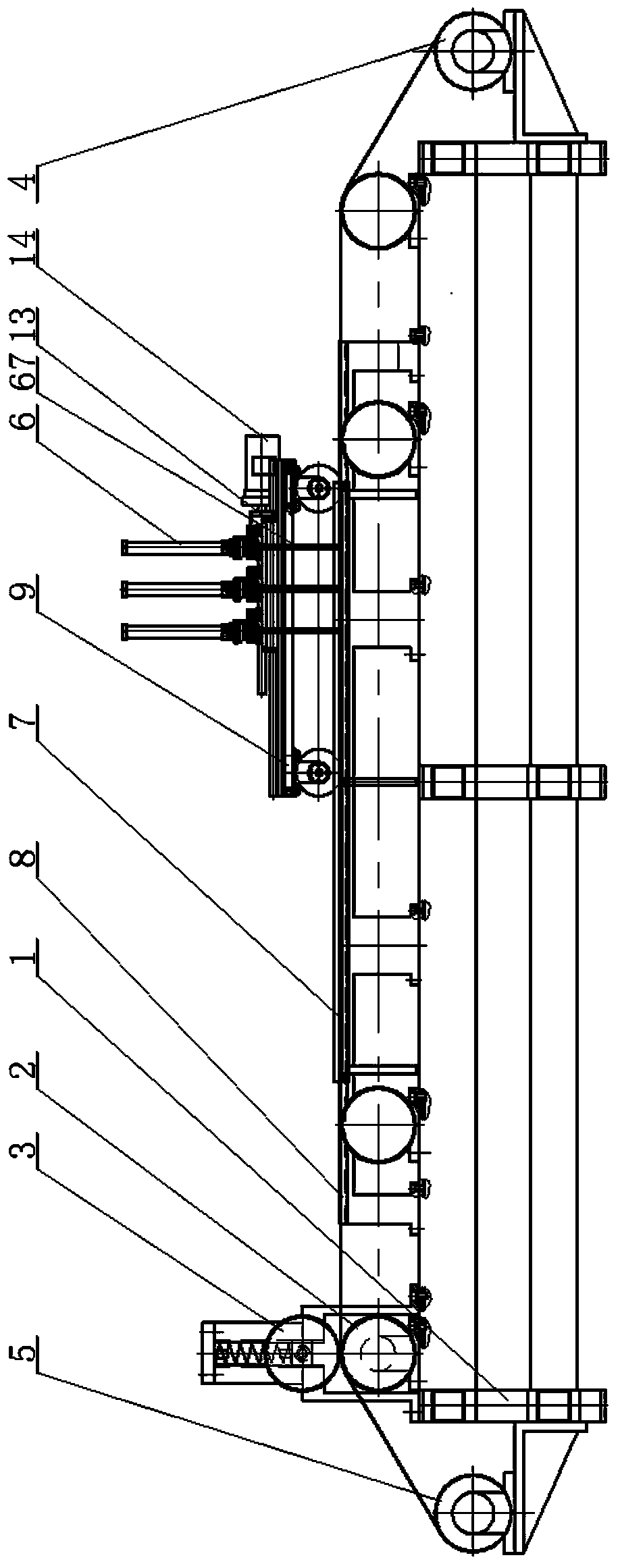

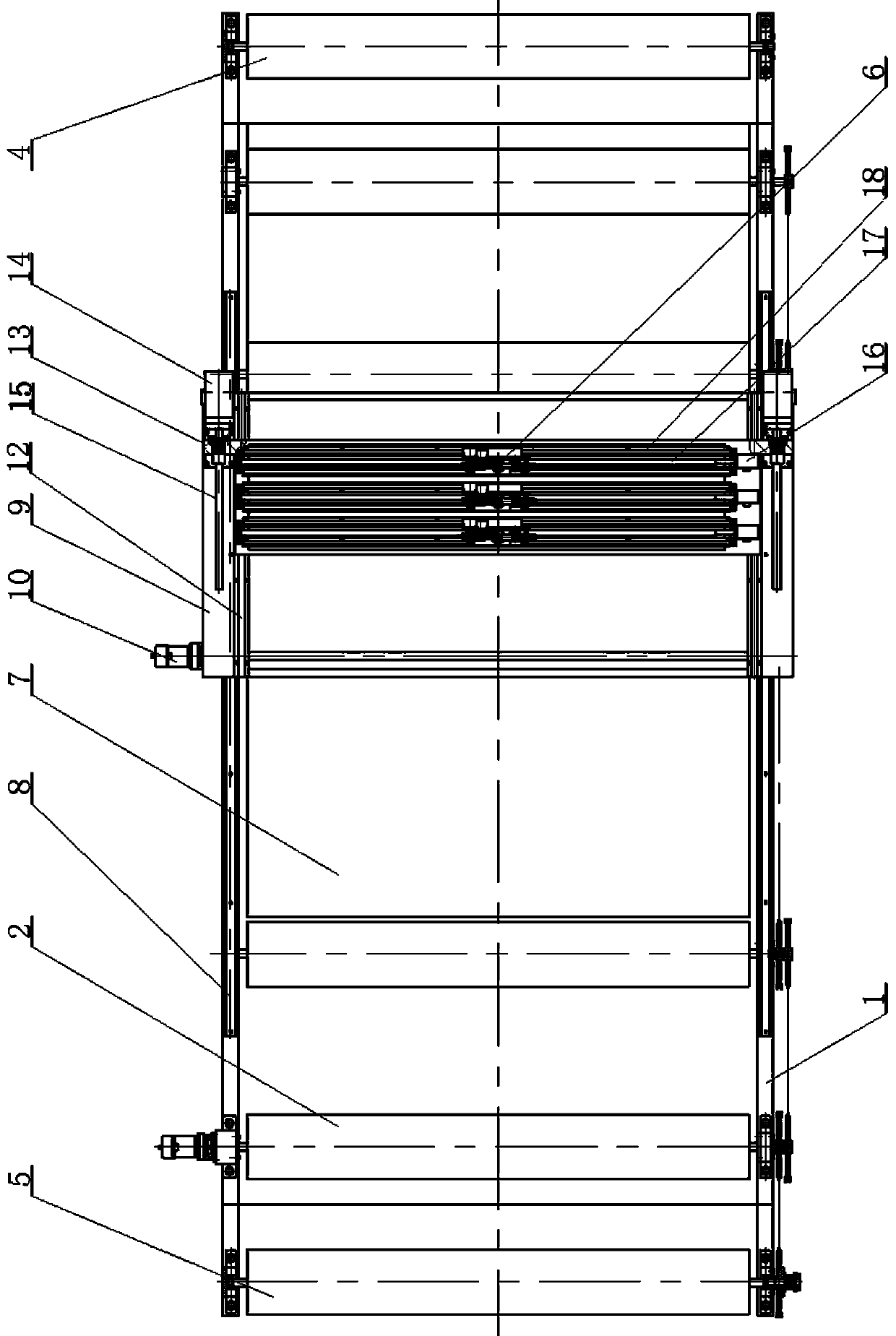

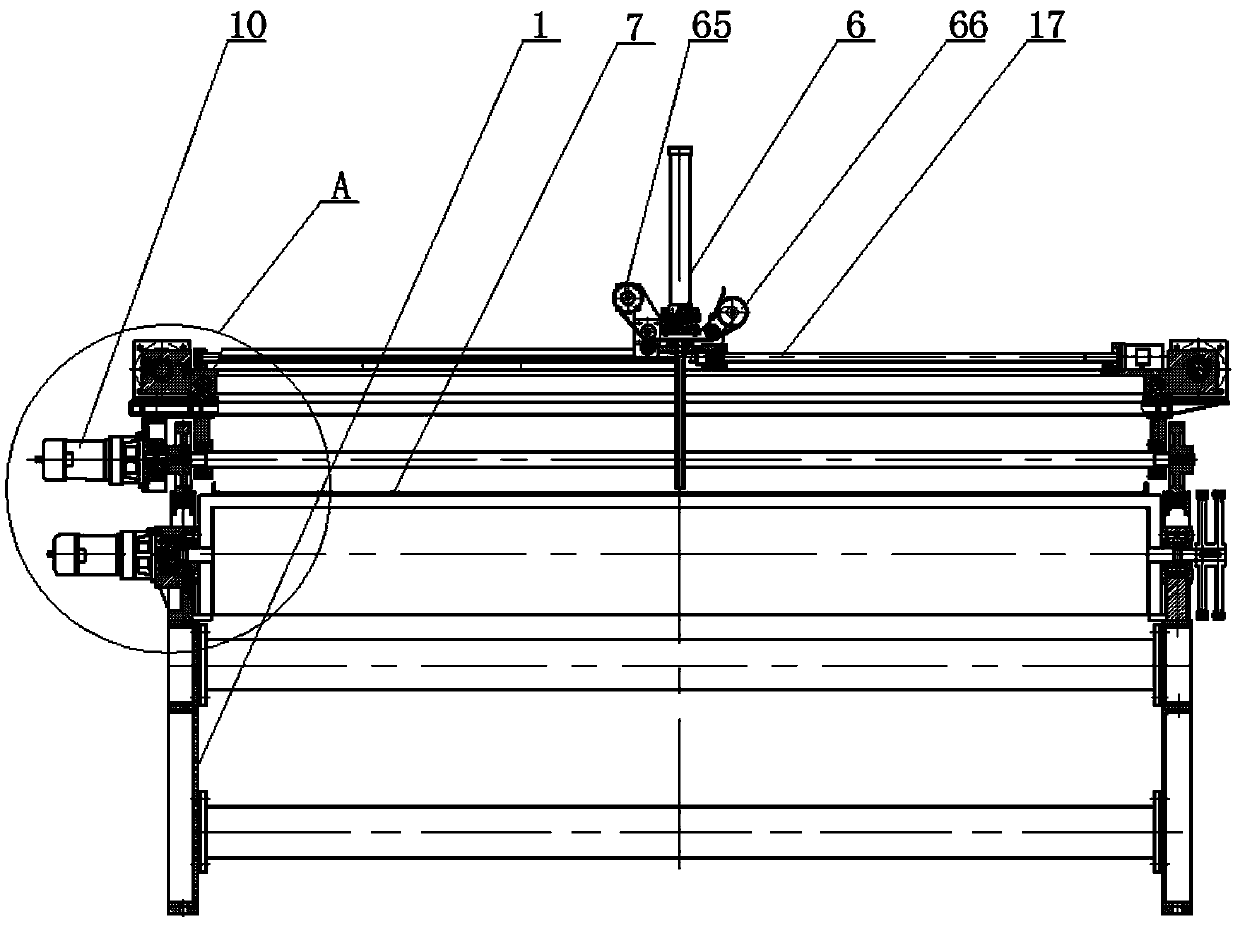

[0021] Depend on Figure 1 to Figure 8 As shown, a cloth embossing automatic equipment, including machine base 1, driving roller 2, pressure roller 3, cloth reel 4, cloth take-up roller 5 and embossing device 6, cloth reel 4 and cloth take-up roller 5 They are respectively installed at both ends of the machine base 1, and the middle part of the machine base 1 is provided with a cloth backing plate 7, and the cloth on the cloth reel 4 passes through the cloth backing plate 7 and the pressure roller 3 under the action of the driving roller 2, and then rolls on the cloth for collection. On the roller 5, guide grooves 8 are provided on both sides of the frame 1, and a large crane 9 is arranged above the guide groove 8. The large crane 9 is driven by a large crane motor 10, and the output shaft of the large crane motor 10 is equipped with Gear 11, rack is installed in guide gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com