Paving equipment for ballastless track roadbed support layer of high-speed railway roadbed

A ballastless track and high-speed railway technology, applied in the directions of roads, tracks, roads, etc., can solve the problems of small distance between the arrival and departure line and the platform wall, difficult to control performance and construction quality, and large size of paving equipment to prevent splashing. , reduce construction costs and improve the effect of sustainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

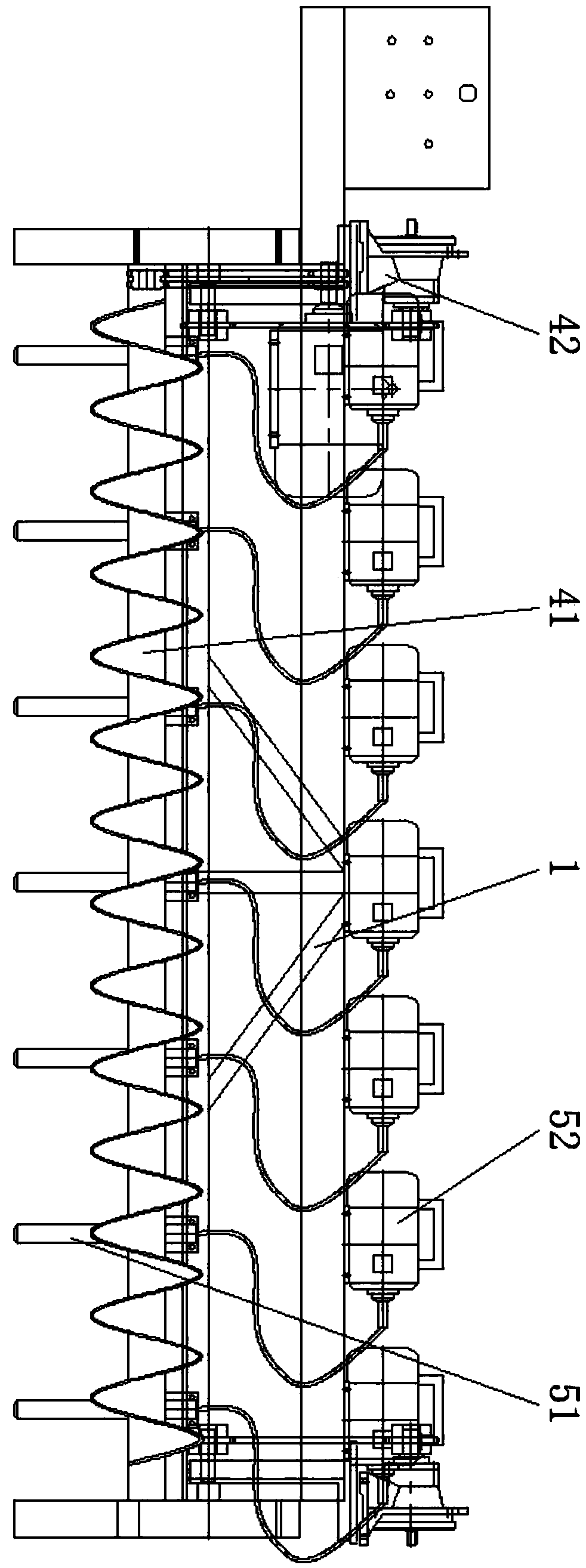

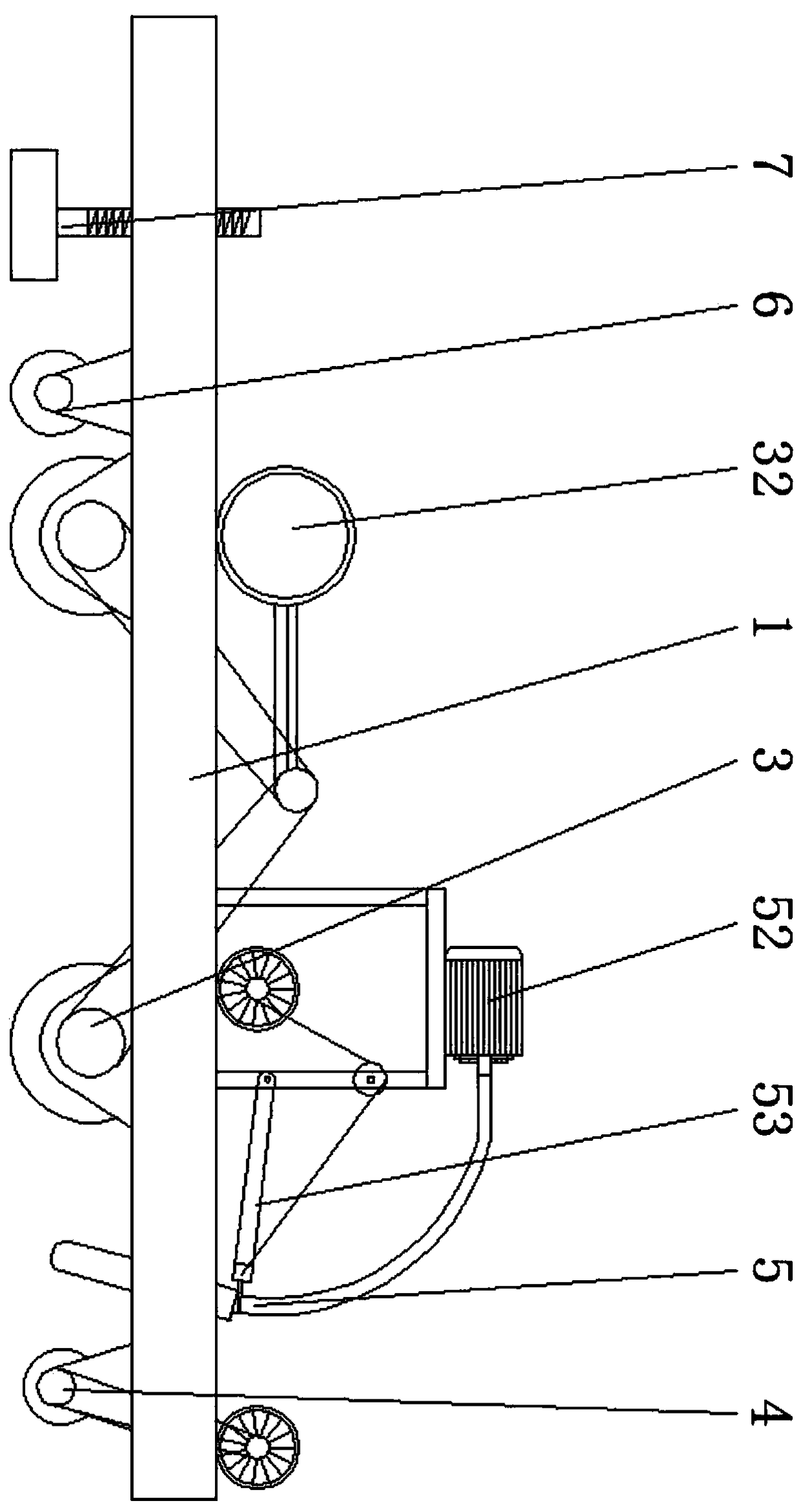

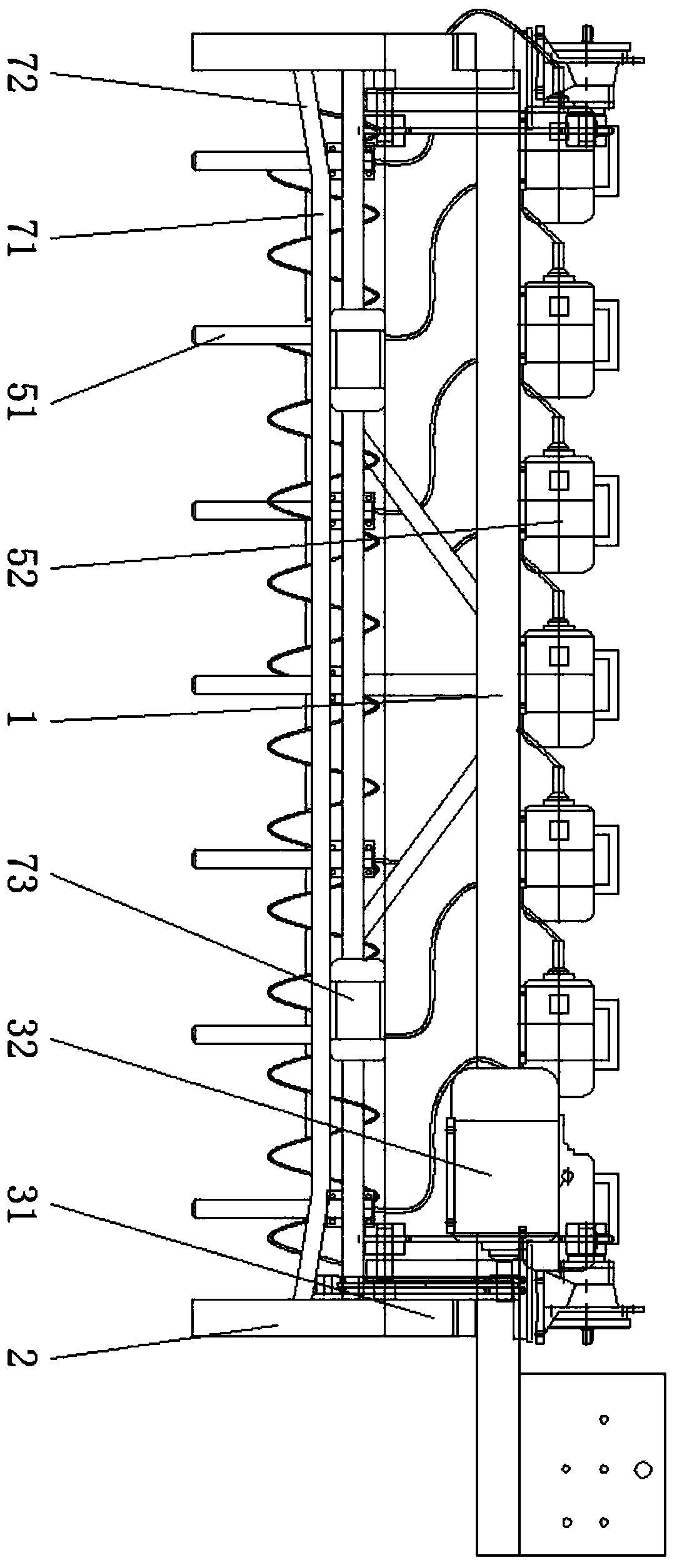

[0027] see Figure 1-3 , in this embodiment, a kind of paving equipment for the support layer of ballastless track subgrade of high-speed railway subgrade, comprises frame 1, and frame 1 is provided with distributing part 4, vibrating part 5, roller 6 and Leveling section 7, the frame 1 lower end is provided with walking section 3, includes the walking wheel 31 that is arranged on both sides of frame 1 and the walking motor 32 that is connected with driving wheel 3 powers in the walking section 3, and walking motor 32 is connected with driving device by transmission device. The walking wheels 31 are connected, the supporting formwork 2 is provided under the frame 1, and four traveling wheels 31 are provided with rolling arrangement above the supporting formwork 2;

[0028] The cloth part 4 is provided with a spiral roller cage 41, and the spiral roller cage 41 is slidingly connected with the frame 1 up and down, so that the upper and lower positions of the spiral roller cage 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com