A shield propulsion system control method for anti-offset load

A technology of a propulsion system and a control method, which is applied in earth-moving drilling, mining equipment, tunnels, etc., can solve problems such as difficulties, achieve uniform thrust, increase force, and avoid segment rupture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described below in conjunction with examples and accompanying drawings.

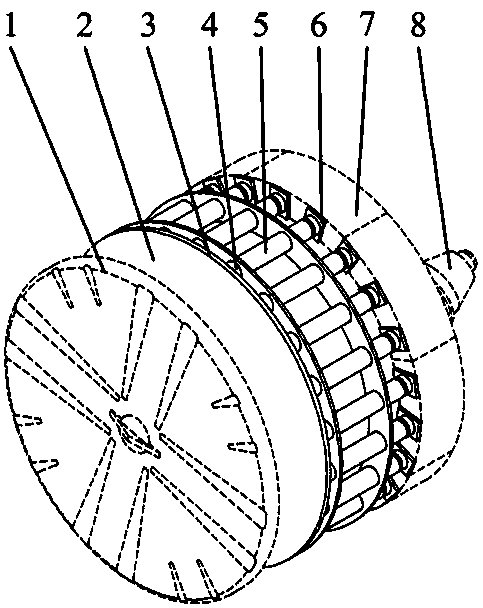

[0022] like figure 1 As shown, it mainly includes a cutter head 1, a shield body 2, a circular partition 3, a hydraulic control valve 4, a hydraulic cylinder 5, a pressure-resistant hard rubber block on the circular partition 3, and a hydraulic reversing valve on the hydraulic cylinder 5. 4 Control expansion and contraction, the left end of the hydraulic cylinder 5 is lined with a pressure-resistant hard rubber block and the circular partition 3 is fixed, the right end is pushed on the segment (7) through the support shoe (6), and the cutter head 1 cuts rocks and soil through the spiral Conveyor 8 conveys out, and the right end of hydraulic cylinder 5 pushes on segment 7 by support shoe 6.

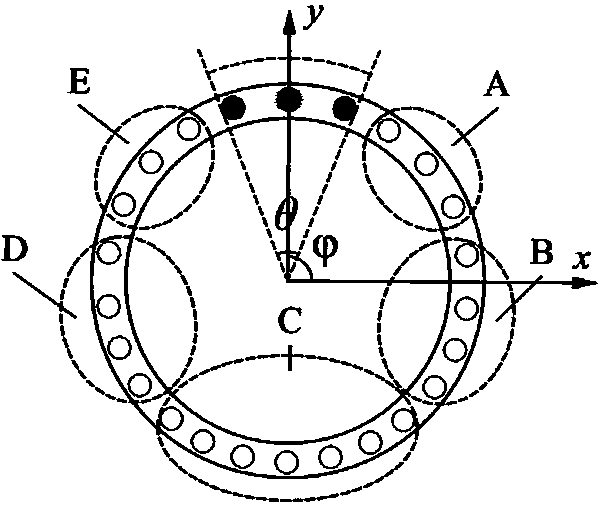

[0023] like figure 2 As shown, several hydraulic cylinders are arranged in a ring, equidistant, continuous and uniform on the system, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com