Pipe connection and assembly body

An assembly and pipe connection technology, applied in the direction of sleeve/socket connection, pipe/pipe joint/pipe fitting, passing element, etc., can solve the problems of difficult to maintain waterproof sealing performance, multi-manpower and time, cumbersome and other problems, and reduce construction costs. Cost, simple pipe connection, and the effect of reducing working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

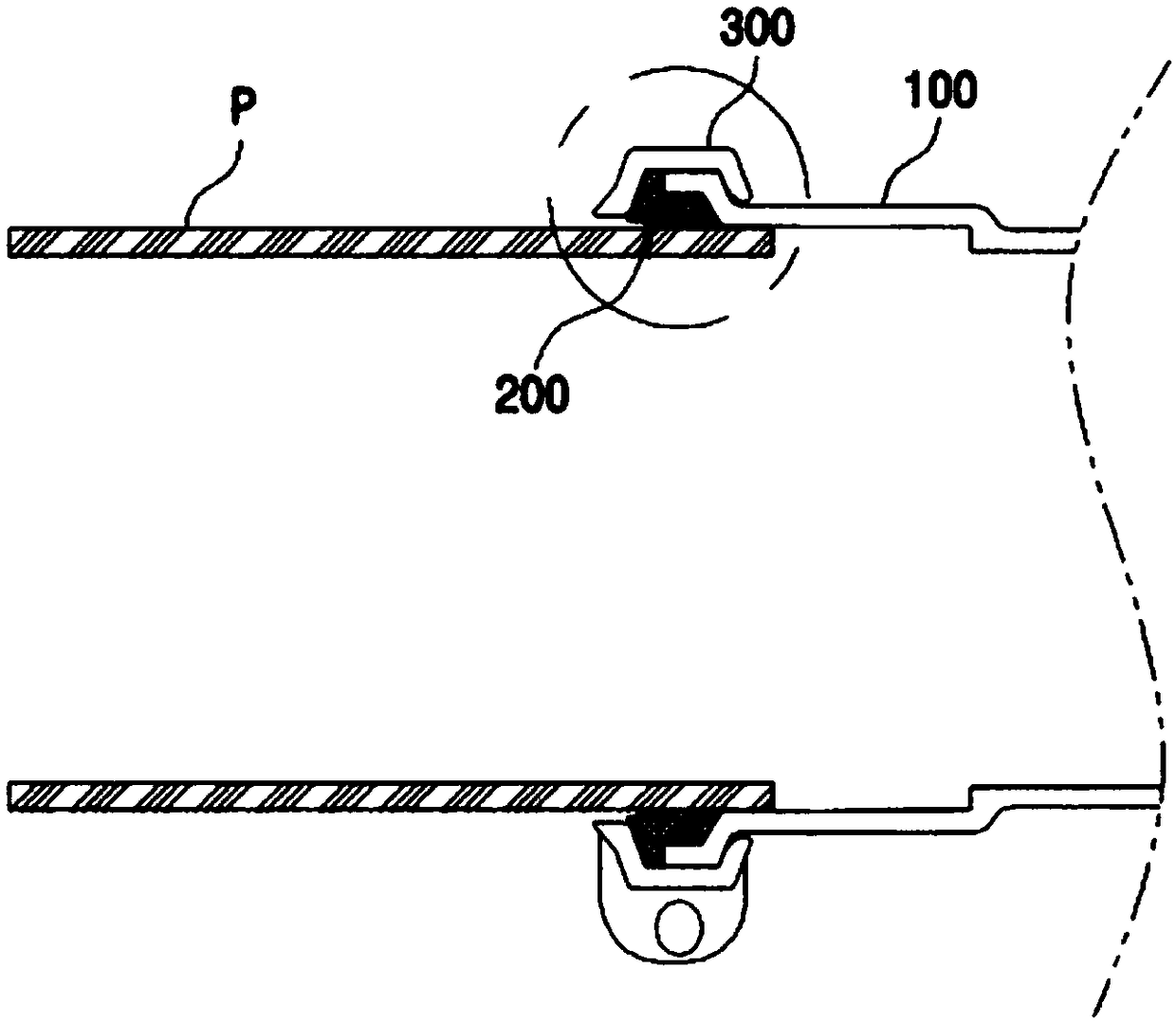

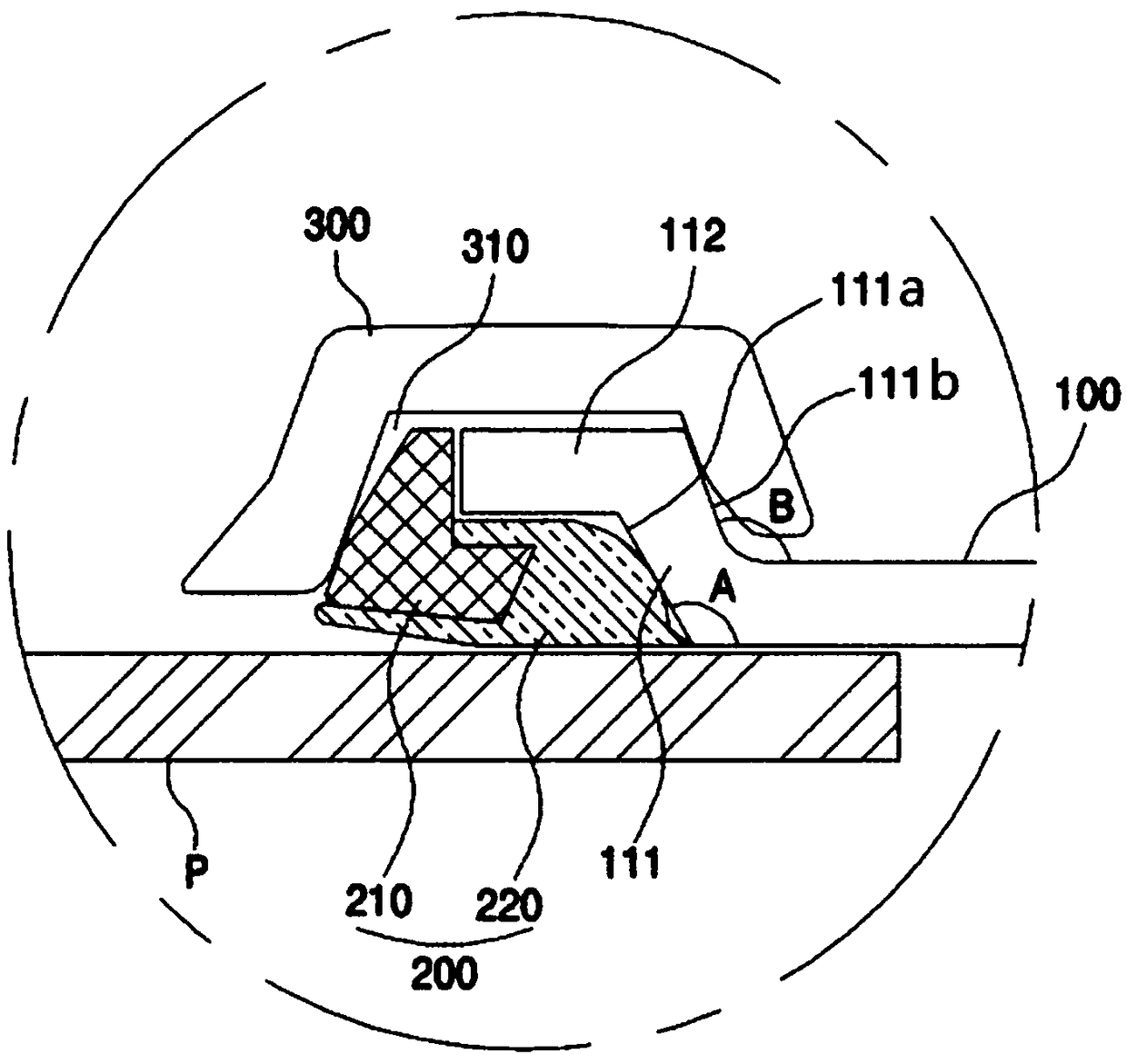

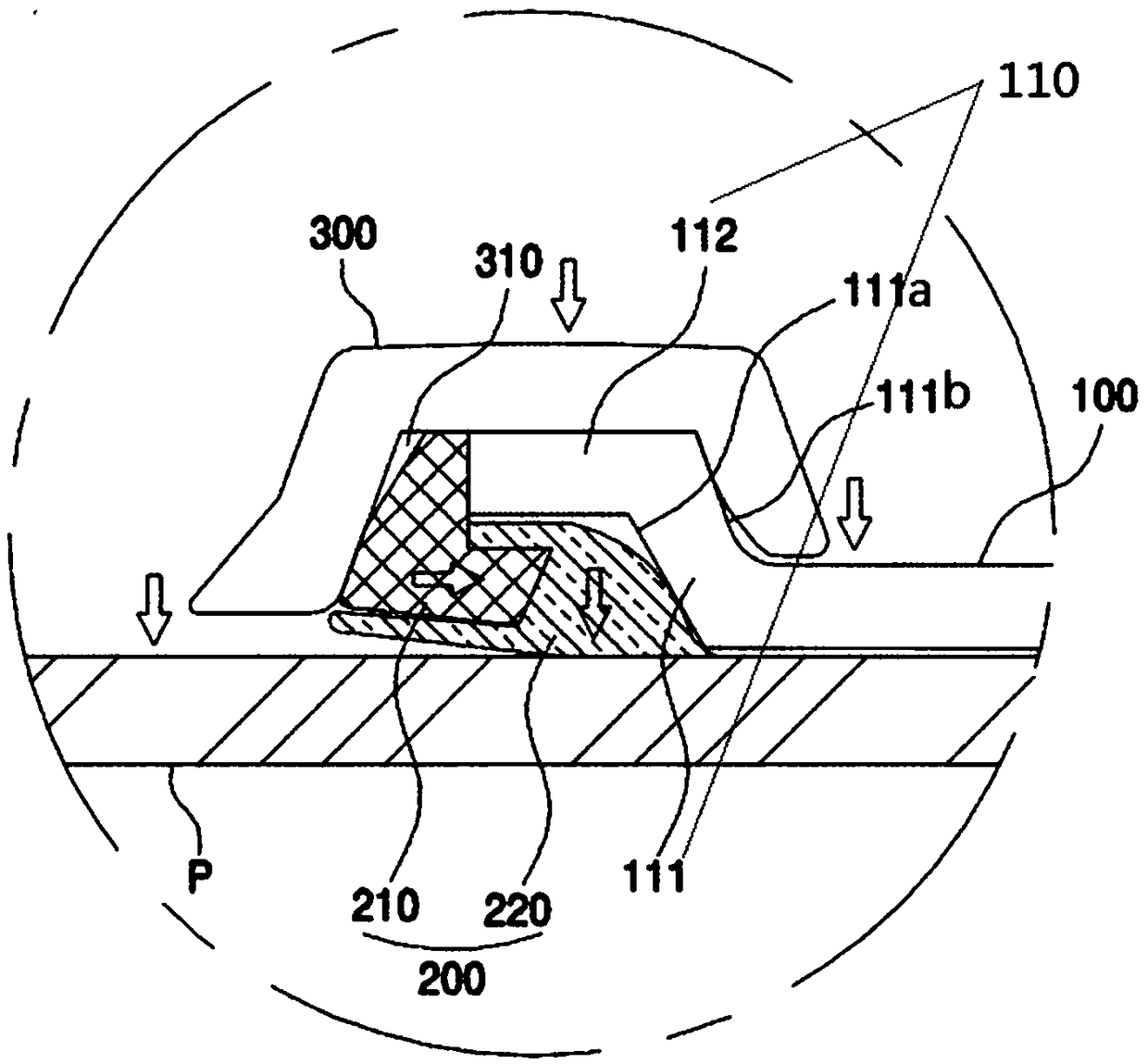

[0027] First, after inserting and combining the pressure ring 210 and the elastic ring 220 and inserting the pressure ring 220 into the expansion port 110 , pass the expansion port 110 and the pressure ring 210 with the jig 300 . The diameter port 110 allows the pipe P to be connected to be inserted into the pipe joint 100. By tightening the clamp 300, the pressure ring 210 pressurizes the elastic ring 220, and on the outer peripheral surface of the pipe P to be connected, the elastic ring 220 The pressurized contact surface 221 and the fins 223 are in close contact, so that the pipe joint 100 and the pipe P to be connected can be airtightly connected to each other.

[0028] Therefore, the elastic ring 220 for watertightness and the pressurizing ring 210 for pressurizing the elastic ring 220 are integrated as a pipe connection assembly for connecting and fixing the pipe P to be connected and the pipe joint 100. Installed inside the pipe joints 100, the clamps 300 are arranged ...

Embodiment 2

[0030] The pipe joint 100 is branched into multiple directions to be inserted into the pipes P to be connected, and an enlarged diameter opening 110 with an inner diameter gradually expanding is formed at the end. In addition, the blocking body 250 includes a pressure plate 260 disposed opposite to one of the enlarged diameter openings 110 of the respective enlarged diameter openings 110 and blocking the enlarged diameter opening 110 of the one side, and a pressurizing plate 260 disposed on the pressurizing opening 110 . The first elastic ring 270 between the plate 260 and the enlarged diameter port 110 is formed. In addition, the pressurizing body 200 includes a pressurizing ring 210 disposed opposite to the enlarged diameter opening 110 on the other side except the enlarged diameter opening 110 on one side of the respective enlarged diameter openings 110 and a pressurizing ring 210 connected to the pressurizing One side of the ring 210 is connected to and inserted into the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com