Heat exchange promoting member and heat exchanger

A heat exchanger and component technology, applied in the field of heat exchange promoting components and heat exchangers, can solve the problems of inability to apply louver fins, no heat conduction promoting method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

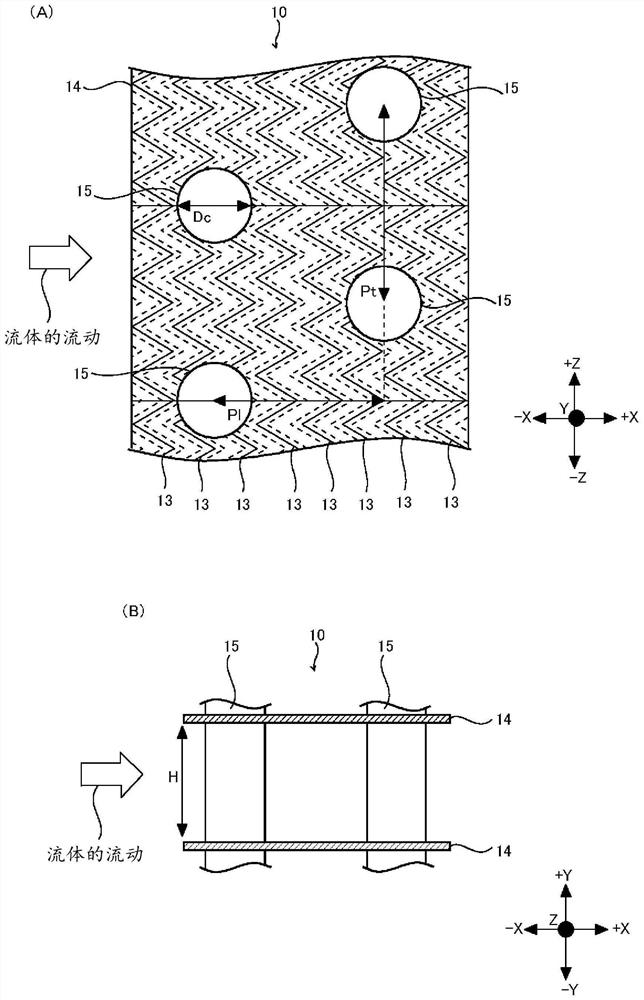

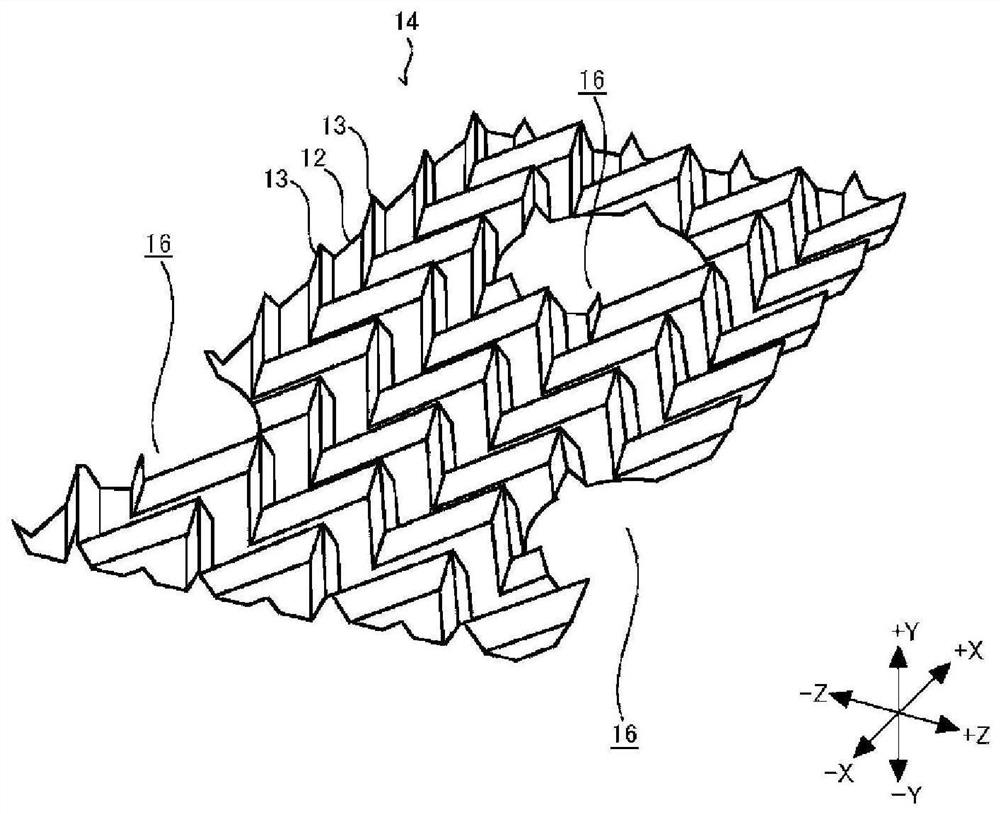

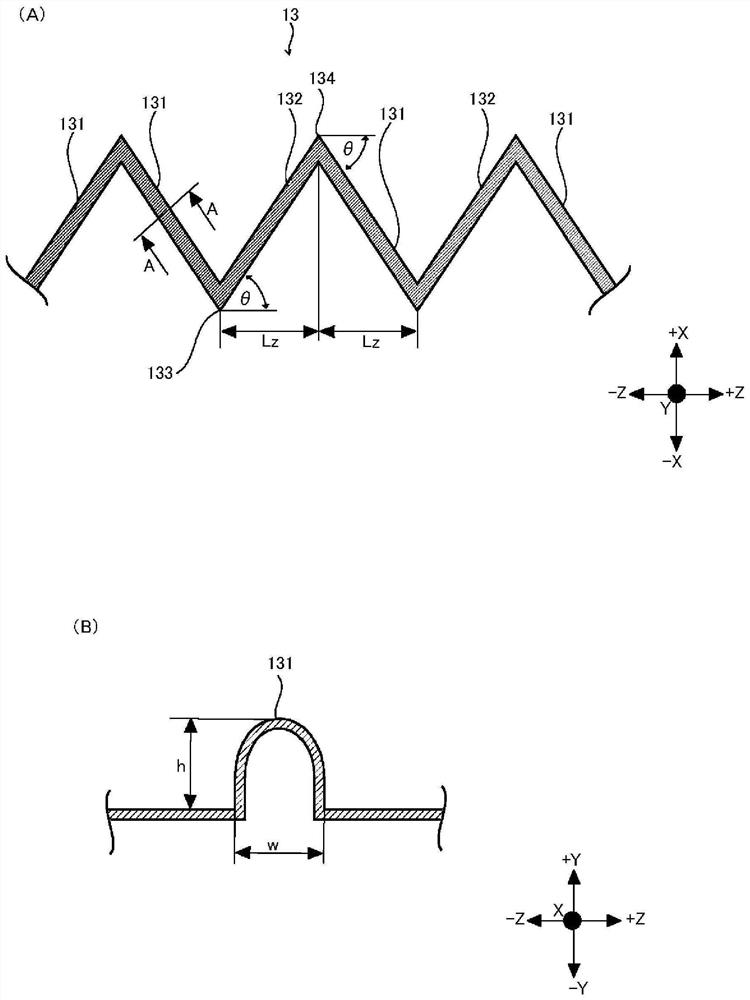

[0052] Hereinafter, embodiments of the present invention will be described in detail based on the drawings. In the following description, the case where the heat exchange promoting member of the present embodiment is applied to a fin-and-tube heat exchanger is exemplified, but the heat exchange promoting member of the present embodiment can also be applied to heat exchangers of other types, such as It can be applied to a heat transfer surface of a plate-type heat exchanger, a heat exchanger provided with a rectangular flow path, specifically, a heat transfer surface of an EGR cooler, or the like. In the following description, the X direction is a direction parallel to the direction in which the fluid flows, the Y direction is the thickness direction of the heat sink 14 , and the Z direction is a direction orthogonal to the X direction and the Y direction.

[0053] refer to figure 1 , the structure of the heat exchanger 10 will be described. figure 1 (A) is a view of the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com