Transmission gear

A transmission device and a rotating shaft technology, applied in transmission devices, fluid transmission devices, control devices, etc., can solve the problems of large-scale transmission devices, complex working oil passages, and large flow resistance of working oil, so as to improve transmission efficiency and avoid Necessary strength, effect of suppressing flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Next, an embodiment of the present invention will be described based on an embodiment of the present invention shown in the drawings.

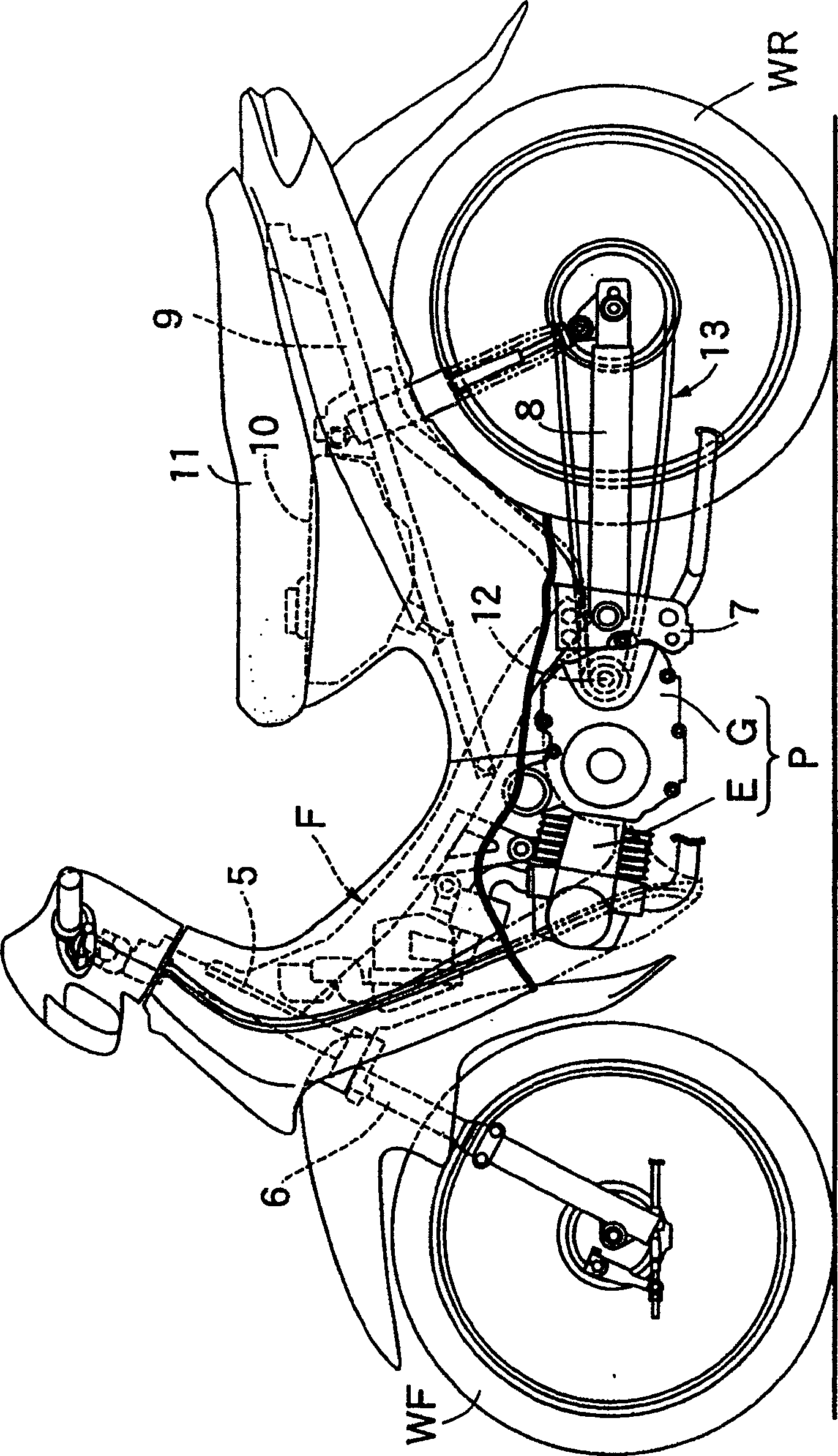

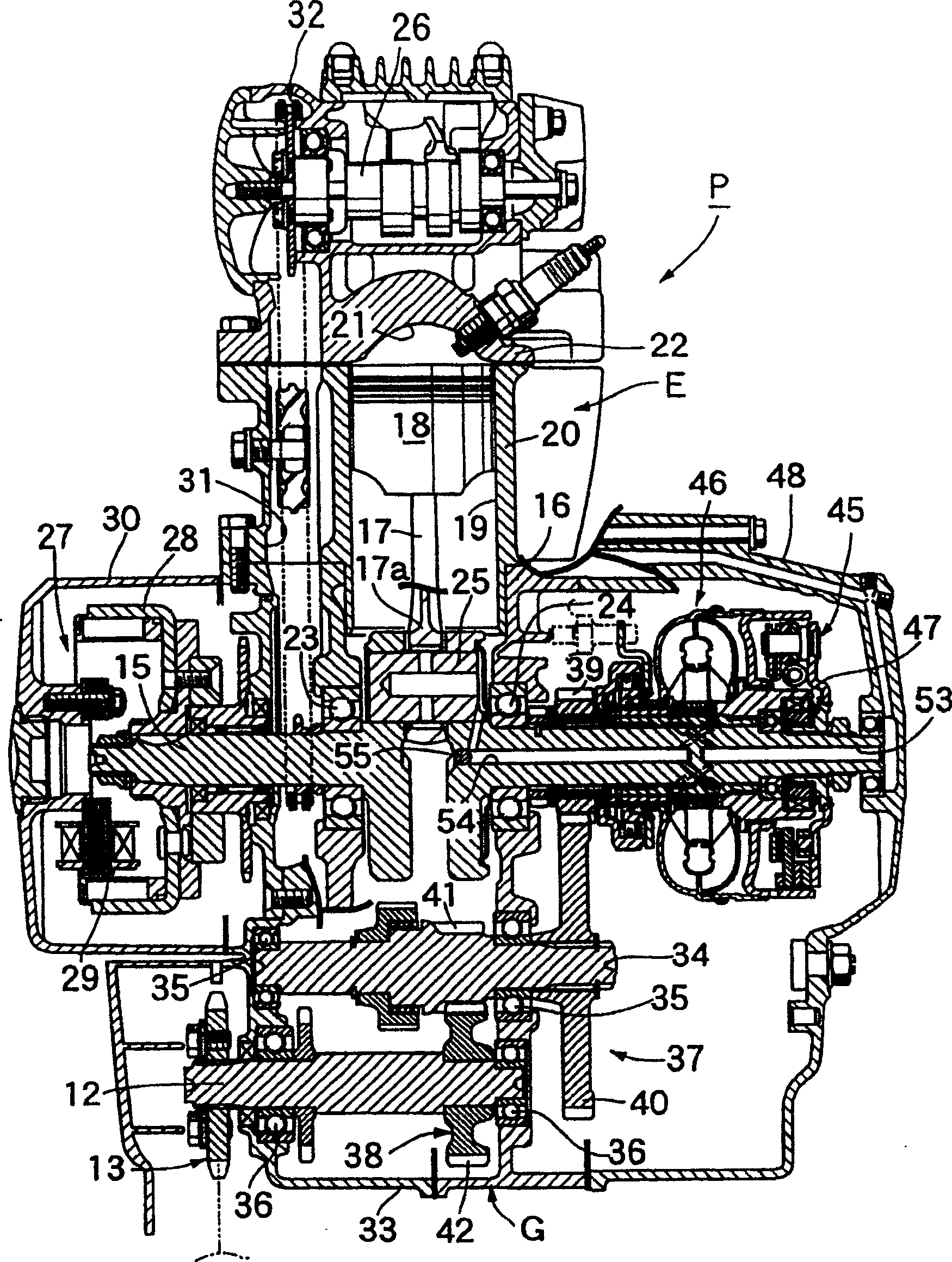

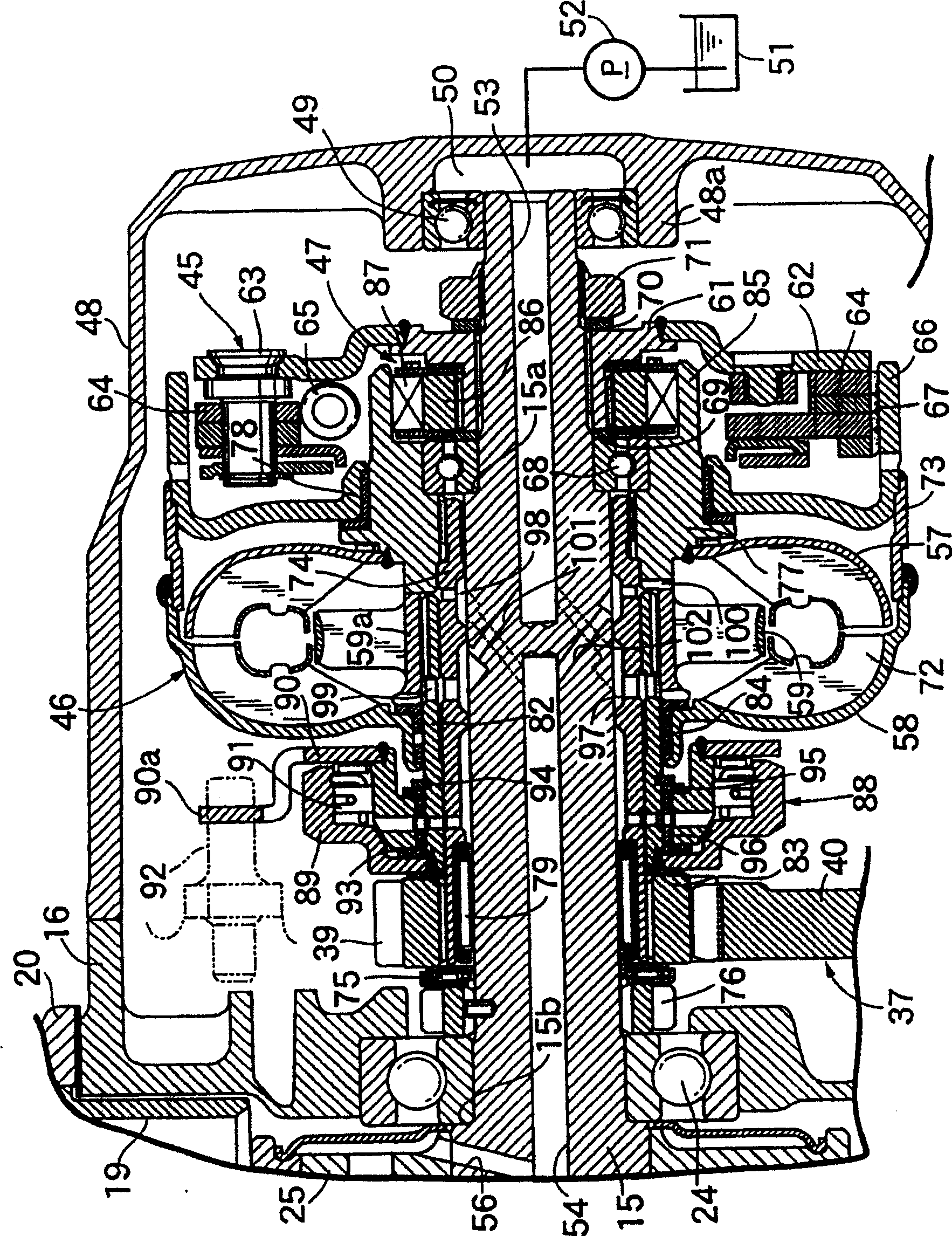

[0017] Figure 1 ~ Figure 3 represents an embodiment of the present invention, figure 1 is a side view of a motorcycle, figure 2 is a longitudinal sectional view of the power unit, image 3 Yes figure 2 Sectional view of the main part.

[0018] first, figure 1 Among them, the front fork 6 is supported in a turnable manner on the head pipe 5 equipped at the front end of the frame F of the motorcycle, and the front fork 6 pivotally supports the front wheel W. The pivot plate 7 supports the swing arm 8 so as to be able to swing up and down, the rear end of the swing arm 8 pivotally supports the rear wheel WR, and the fuel tank 10 and The seat 11 covers the fuel tank 10 .

[0019] The power unit P composed of the engine E and the reducer G is assembled on the frame F, and is arranged between the pivot plate 7 and the front wheel WF...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com