Heat exchanger and method of producing the same

A technology for heat exchangers and manufacturing methods, applied in the direction of heat exchanger types, indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of insufficient reliability of fluid leakage, expensive heat exchangers, and accompanying difficulties, etc. Easy to manufacture, cheap to provide, and the effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

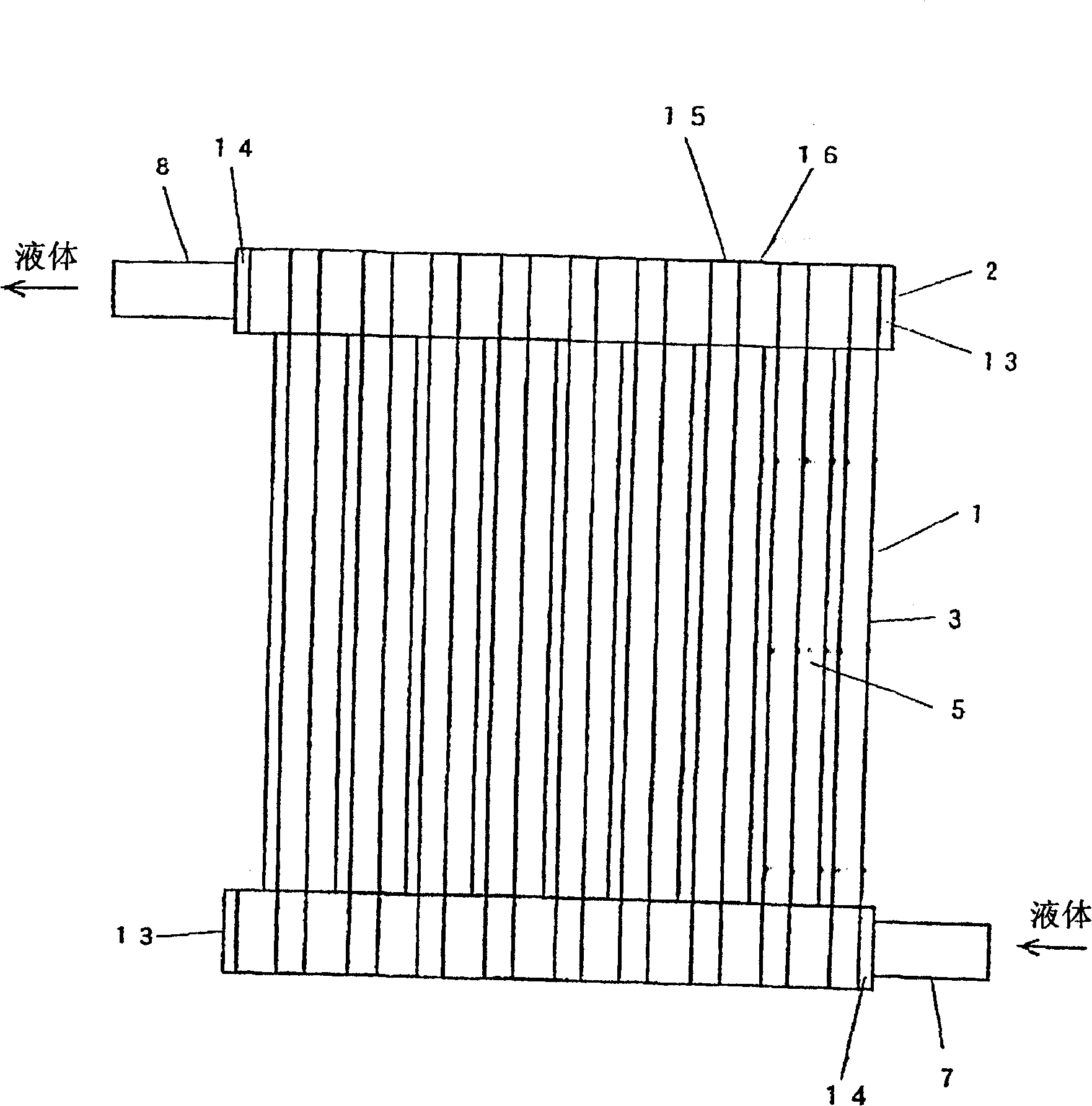

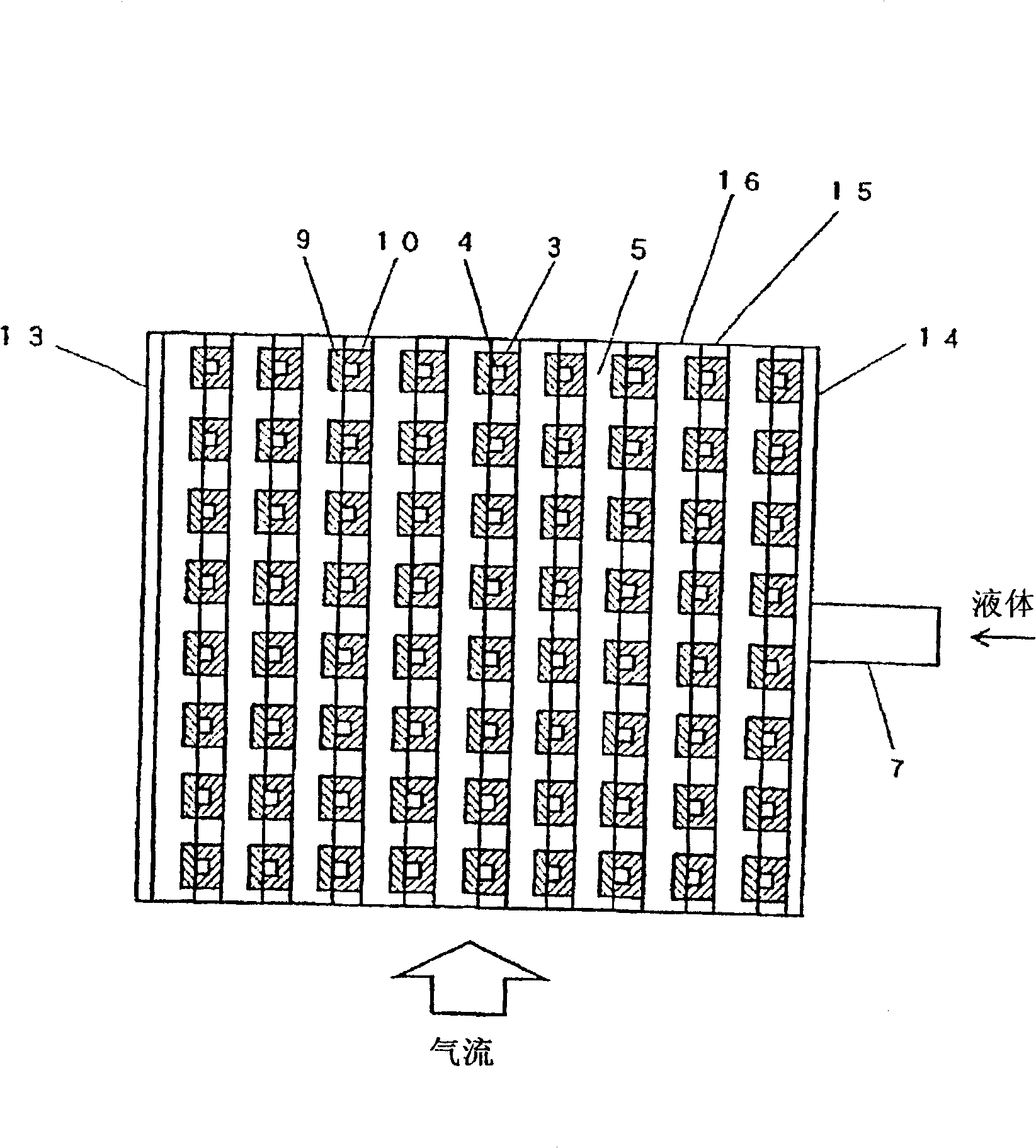

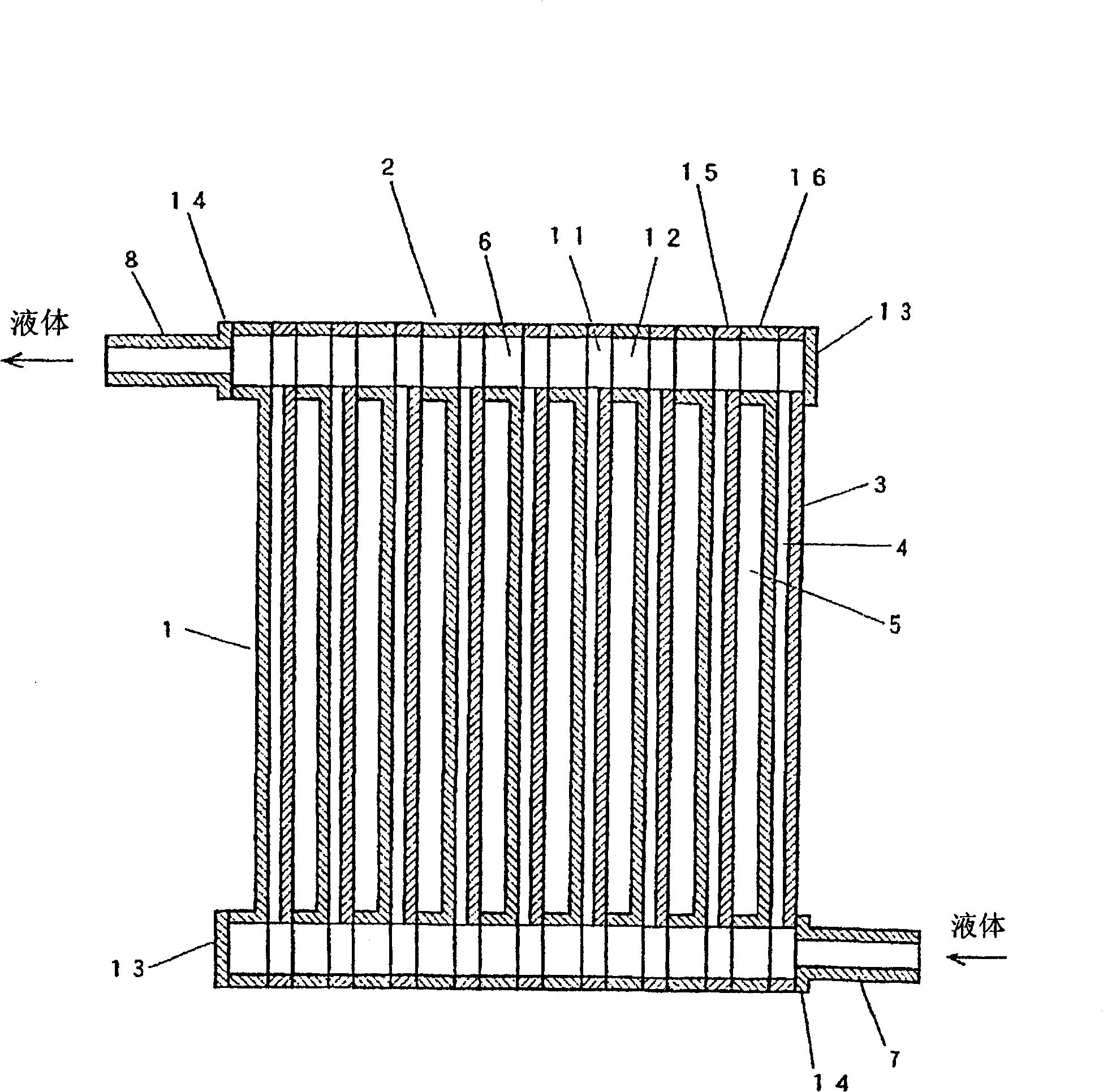

[0064] figure 1 is a front view of the heat exchanger according to Embodiment 1 of the present invention, figure 2 is a sectional view showing the heat exchanger in a direction perpendicular to the tube axis of the heat exchange section, image 3 is a sectional view showing the heat exchanger in the tube axis direction of the heat exchange portion.

[0065] exist Figure 1 to Figure 3 Among them, the heat exchanger is composed of a heat exchange unit 1 and headers 2 at both ends of the heat exchange unit 1 . The heat exchange unit 1 has tubes 3 , tube inner flow paths 4 , and tube outer flow paths 5 arranged in a grid pattern. The header part 2 has a branch flow path 6 , an inflow pipe 7 , and an outflow pipe 8 inside, and the in-pipe flow path 4 is connected to the branch flow path 6 . The cross-sectional shape of the pipe 3 is approximately square, and is composed of a strip-shaped long plate 9 and a long plate 10 with a U-shaped cross-sectional shape. The branch chan...

Embodiment approach 2

[0080] Figure 11 It is a perspective view of the heat exchange part in Embodiment 2 of this invention.

[0081] Figure 12 is a front view of the first substrate of Embodiment 2, Figure 13 is a front view of the second substrate. The heat exchange unit is constituted by alternately laminating first substrates 26 and second substrates 28 . A plurality of first slits 30 and a plurality of second slits 40 are alternately arranged substantially parallel to each other on the first substrate 26 . On the second substrate 28 , a third slit 50 having the same shape as the first slit 30 is provided at substantially the same position as the projection of the first slit 30 .

[0082] Accordingly, since the first slit 30 and the third slit 50 overlap each other on the projected plane, they are communicated with each other to form the tube-outside flow path 60 . In addition, the dimension in the longitudinal direction of the third slit 50 arranged on the second substrate 28 is shorte...

Embodiment approach 3

[0095] figure 1 9 is a perspective view of the heat exchange unit in Embodiment 3 of the present invention. The heat exchange unit is formed by stacking the first substrate 126 between the second substrate 128 . As in the second embodiment, the tube-outside flow path 160 is formed by the first slit 130 and the third slit 150 . In addition, an in-pipe flow path 170 is formed by the second slit 140 and the second substrate 128 . Here, on the inflow side of the external fluid, three first substrates 126 are laminated between the second substrates 128, followed by two, and one is laminated on the outlet end of the external fluid, whereby the in-pipe flow path 170 It becomes larger toward the inflow side of the external fluid in the substrate lamination direction.

[0096] In Embodiment 3, although three rows are arranged in the flow direction of the external fluid, not three rows but multiple rows may be used. In addition, the number of first substrates 126 to be laminated c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com