Fixed coal inventory method and system of closed coal yard

A fixed, coal-coaling technology, which is applied in measuring devices, instruments, surveying and navigation, etc., can solve the problems of slow scanning speed, unguaranteed smooth operation of the coal-panel instrument, and reduced precision of the coal-panel, so as to improve the scanning accuracy and be practical Strong performance and reliable data transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

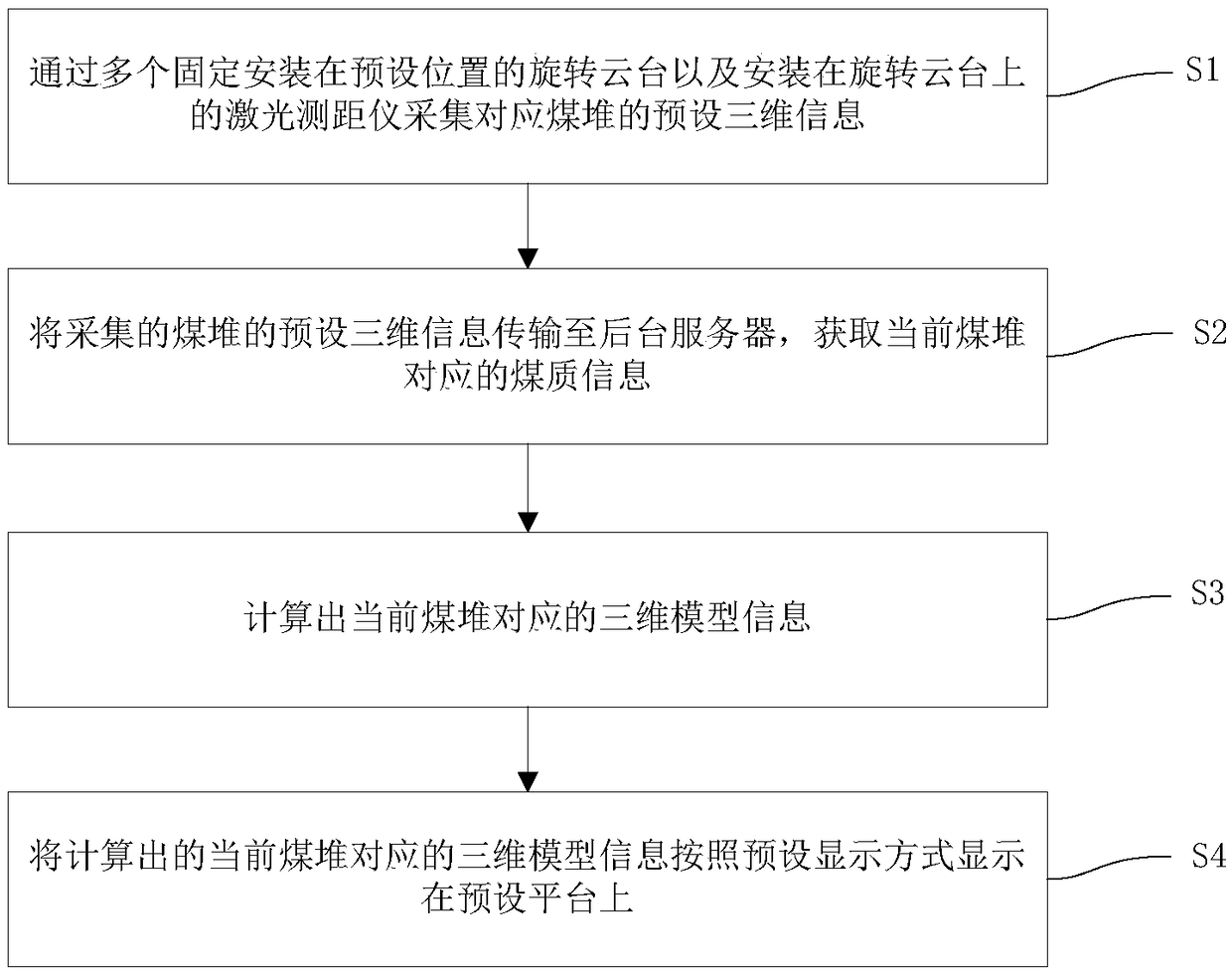

[0065] This embodiment provides a fixed coal-coaling method in a closed coal yard, such as figure 1 , Figure 3 to Figure 8 Shown, this closed coal yard fixed coal method comprises steps:

[0066] S1: Collect the preset three-dimensional information of the corresponding coal pile through multiple rotating pan-tilts fixedly installed at preset positions and laser range finders installed on the rotating pan-tilts;

[0067] S2: Transmit the preset three-dimensional information of the collected coal pile to the background server to obtain the coal quality information corresponding to the current coal pile;

[0068] S3: According to the preset 3D model construction algorithm, combined with the collected preset 3D information and the coal quality information corresponding to the coal pile, calculate the 3D model information corresponding to the current coal pile;

[0069] S4: Display the calculated 3D model information corresponding to the current coal pile on the preset platform ...

Embodiment 2

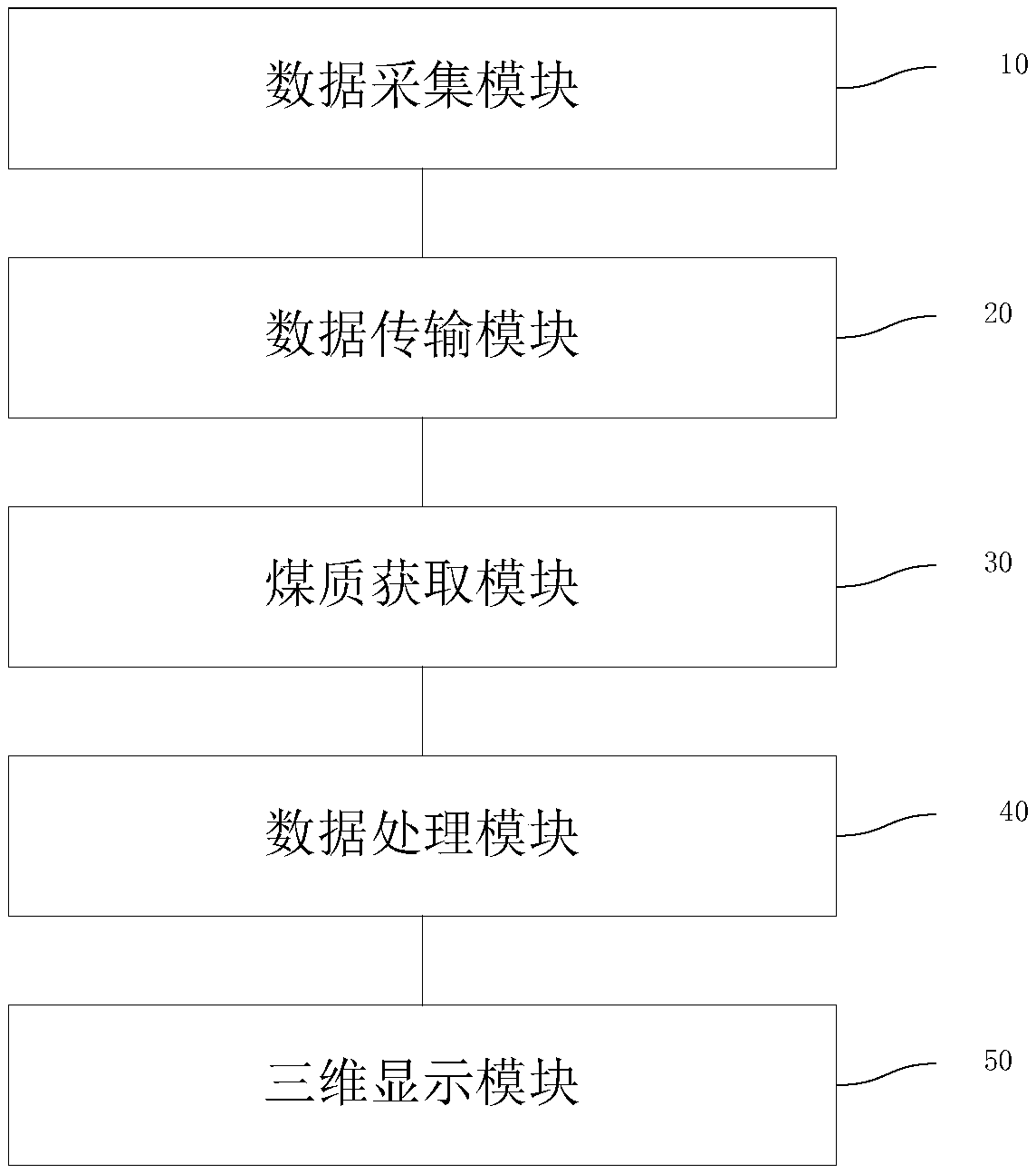

[0100] This embodiment provides a closed coal yard fixed coal system, such as Figure 2 to Figure 8 As shown, the system includes:

[0101] Data collection module, used to collect the preset three-dimensional information of the coal pile;

[0102] The data transmission module is used to transmit the preset three-dimensional information of the collected coal pile to the background server;

[0103] The coal quality acquisition module is used to call the preset coal quality information database and combine the preset three-dimensional information of the collected coal pile to obtain the coal quality information of the current coal pile;

[0104] The data processing module is used to construct an algorithm according to a preset three-dimensional model, and calculate the three-dimensional model information corresponding to the current coal pile in combination with the collected preset three-dimensional information and the coal quality information corresponding to the coal pile;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com