Aeroengine blade vibration test device and method

An aero-engine and vibration testing technology, which is applied in vibration testing, machine/structural component testing, measuring devices, etc., can solve the problems of single clamping blade direction, low test efficiency, single clamping blade specification, etc., to achieve any performance, expand the test range, and ensure the effect of preload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

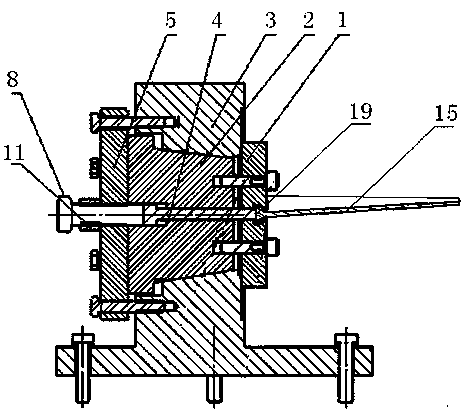

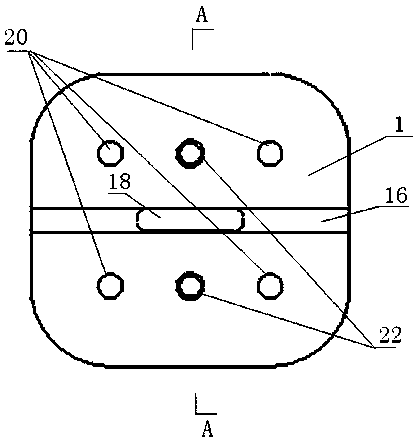

[0052] The difference between this embodiment and Embodiment 1 is that the tenon groove 16 runs through the entire length direction of the rotating disk 1, and the shape of the tenon groove 16 depends on the shape of the blade tenon 19. The blade tenon 19 is in the shape of a fir tree, and the tenon 16 is in the shape of a fir tree type.

Embodiment 3

[0054] The test method of a kind of aeroengine blade vibration test test device of the present embodiment comprises the following steps:

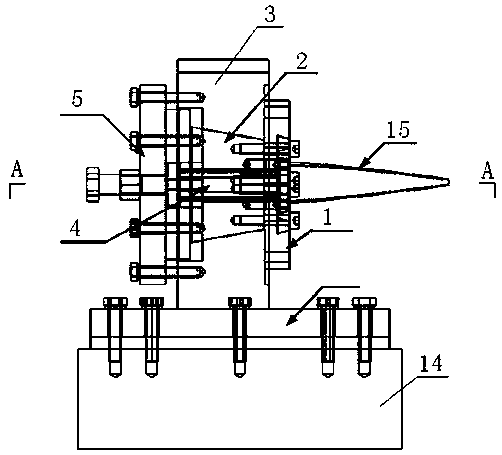

[0055] 1. Install the device main body 3 on the vibrating table 14;

[0056] 2. Put the back cover 2 into the back cover installation chamber 12 of the main body 3 of the device. Since both are provided with tapers, in order to facilitate the subsequent steps, do not use force when putting the back cover 2 into the main body 3 of the device in this step. push tight;

[0057] 3. Determine the shape and size of the tenon and groove of the rotating disk 1 according to the shape and size of the blade tenon 19;

[0058] 4. Install the rotating disk 1 on the rear cover 2 and position it;

[0059] 5. Put the pressing block 4 into the back cover 2, insert the blade tenon 19 into the tenon groove 16 of the rotating disk 1, push the pressing block 4 by hand, make it contact with the blade tenon 19 and make the blade tenon 19 and the rotating disk ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com