Cell short circuit testing device and testing method thereof as well as cylindrical cell piece production winder

A technology of short-circuit testing and battery cells, which is applied in the direction of measuring devices, circuits, conveyors, etc., can solve the problems of short-circuit detection time of battery cells, only 0.5 seconds to 1 second, and short detection time, so as to increase short-circuit detection time, Long-lasting, reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

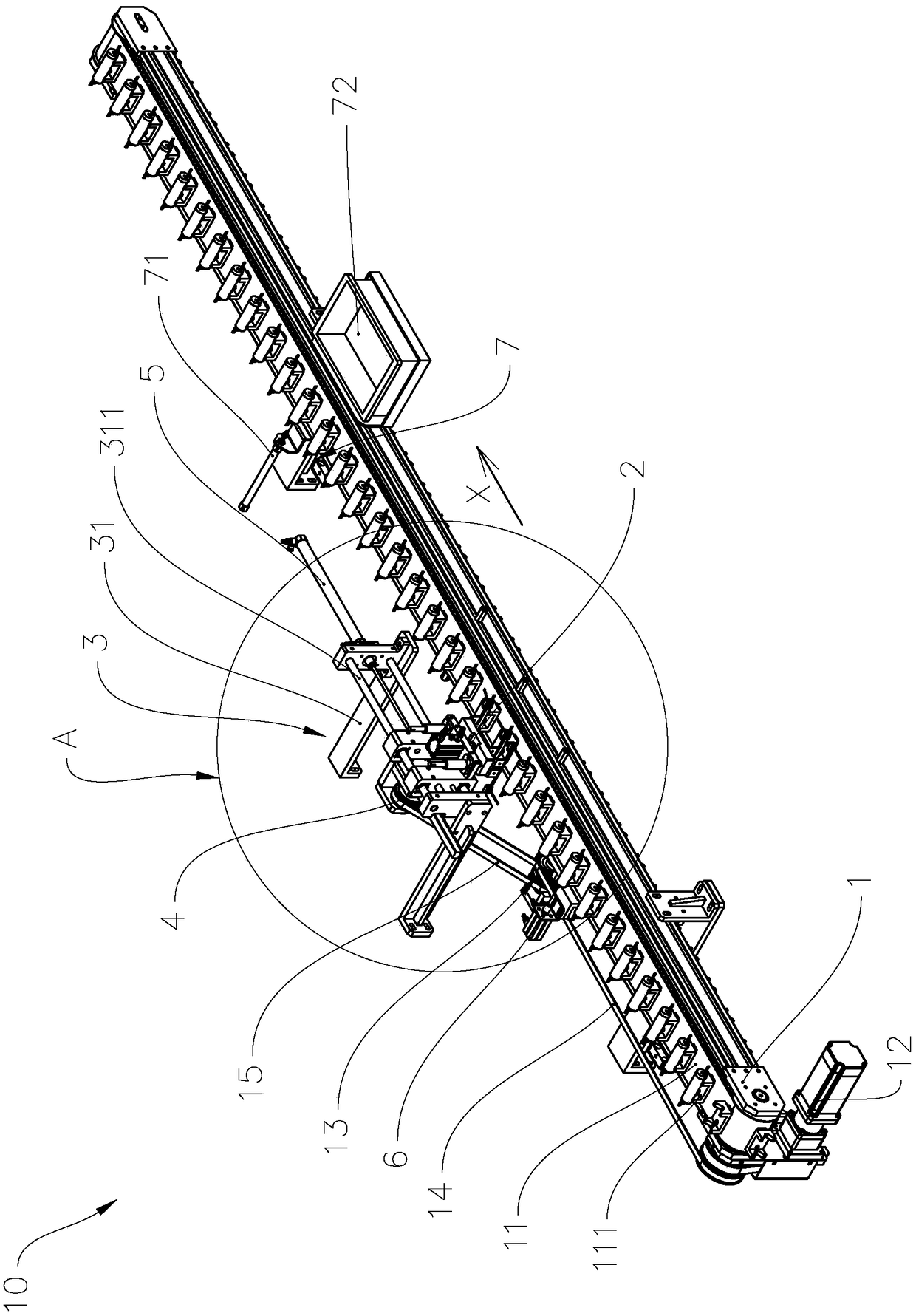

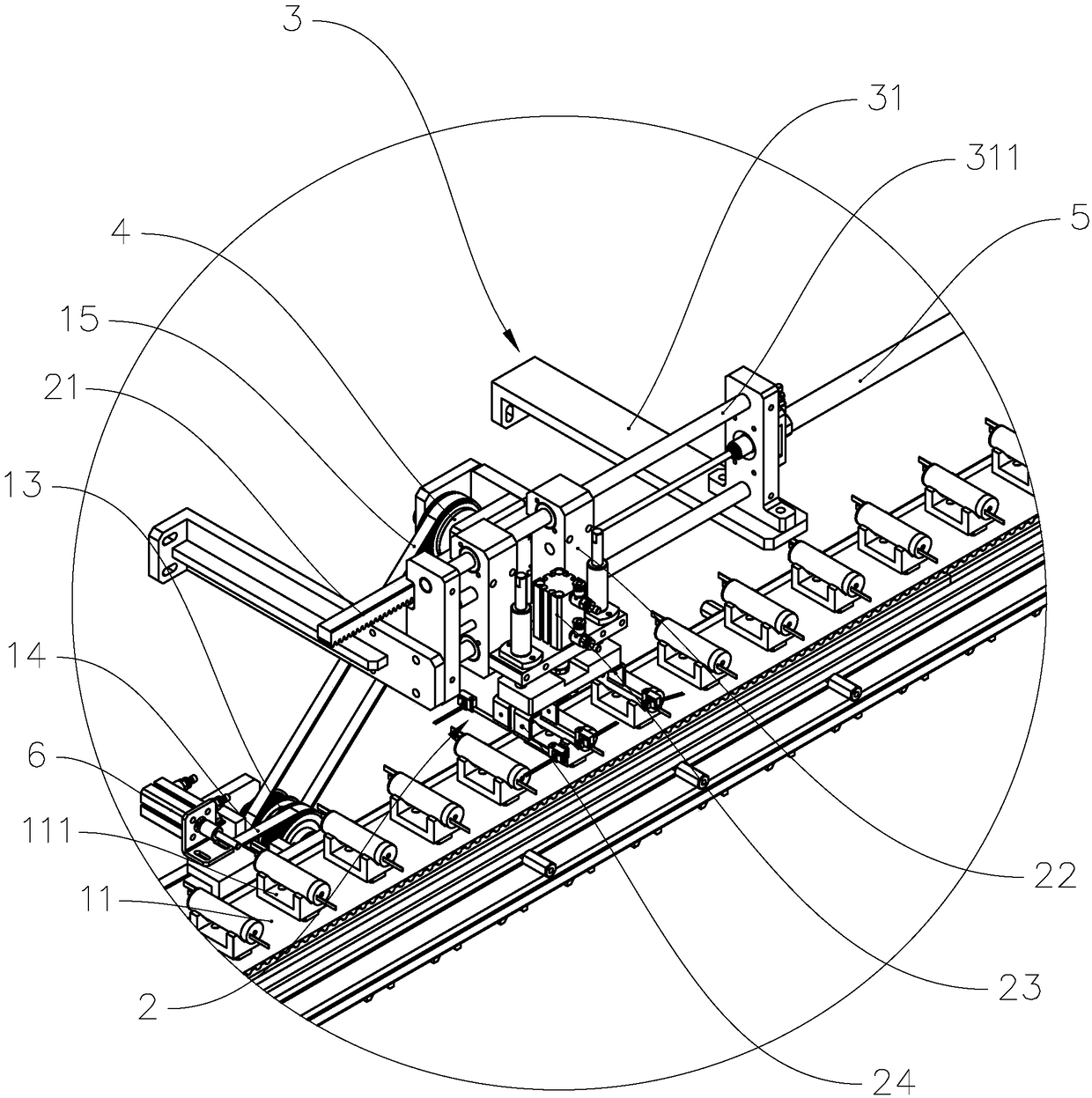

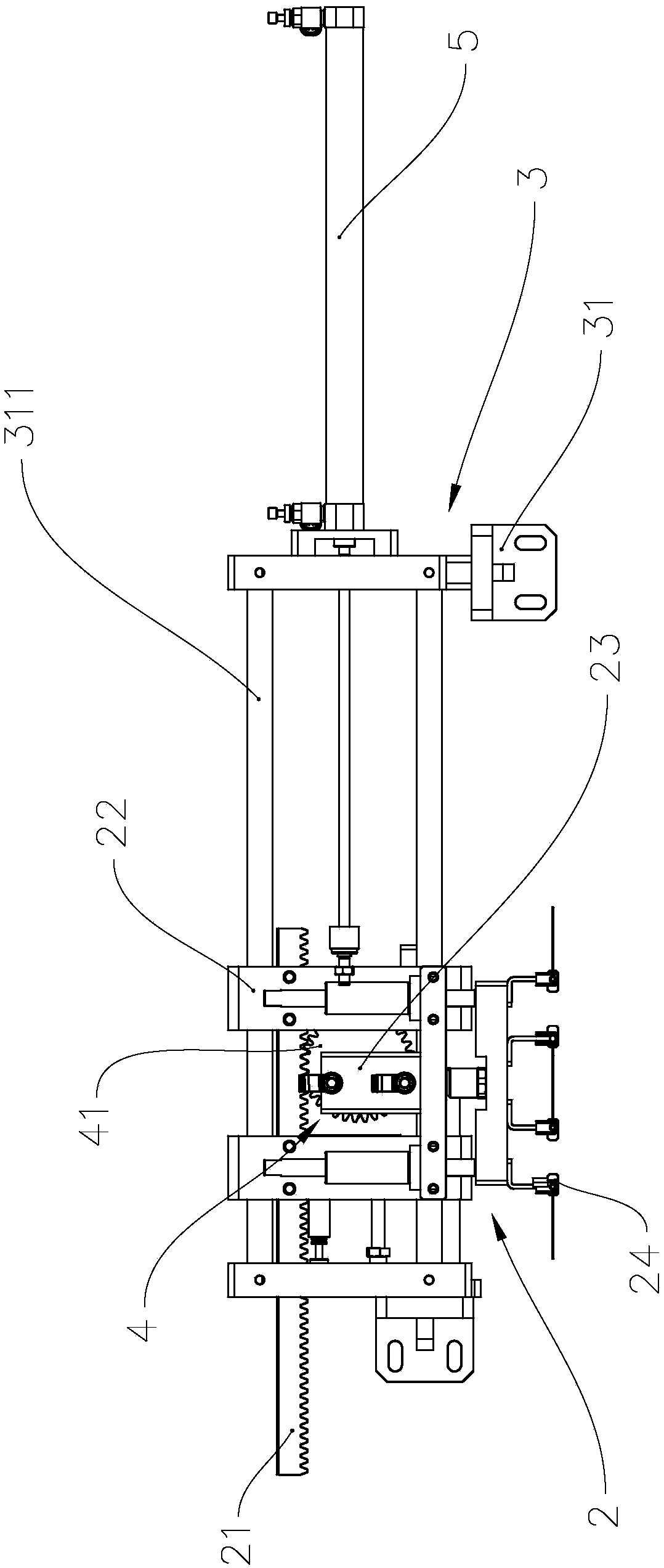

[0035] refer to figure 1 with figure 2 , the winding machine for cylindrical electric core sheet comprises a frame, a winding head and a short-circuit test device 10, wherein the winding head is rotatably connected with the frame around its own axis, and the winding head is used for positive pole pieces, Negative pole pieces, separators, etc. are wound into batteries. And the electric core short-circuit testing device 10 is installed on the frame, and the electric core short-circuit testing device 10 is positioned at the unloading station place of winding head, and electric core short-circuit testing device 10 is used for the electric core that winding head rolls is carried out. Short circuit test to rule out cells with short circuit problems.

[0036] Specifically, such as figure 1 As shown, the cell short-circuit testing device 10 includes a feeding line 1 , a short-circuit testing unit 2 , a guiding unit 3 , a clutch unit 4 , a reset unit 5 , a positioning unit 6 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com