A Modeling Method for Starting Process of Micro Gas Turbine Engine

An engine starting and gas turbine technology, applied in geometric CAD, design optimization/simulation, special data processing applications, etc., can solve the problems of low efficiency, large amount of modeling data, low modeling accuracy, etc. The effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the purpose, technology and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and examples.

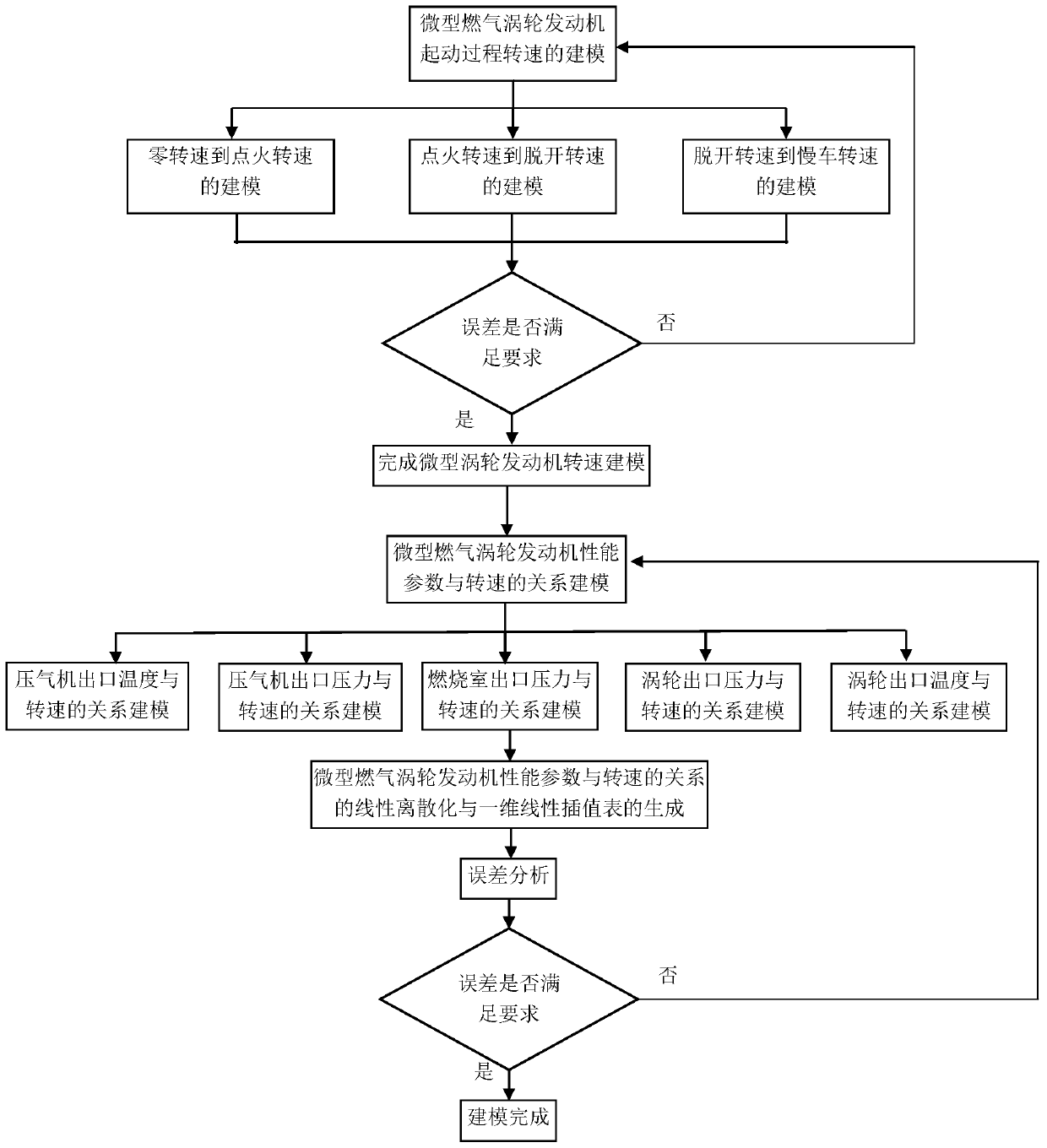

[0028] A method for modeling the starting process of a micro gas turbine engine, comprising the following steps:

[0029] Step 1: The starting process of the micro gas turbine engine is divided into three stages. In the first stage, the engine speed is from zero to the speed at which the turbine starts to generate power, and the engine is completely accelerated by the starter; in the second stage, the turbine starts to generate power. Speed to starter disengagement; the third stage, from starter disengagement speed to idle speed;

[0030] Model the engine starting process in terms of its phases;

[0031] In the first stage, the engine speed is from zero to the speed at which the turbine starts to generate power (that is, from zero speed to ignition spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com