Laser conformal manufacturing method of three-dimensional curved surface of flexible sensor

A flexible sensor, three-dimensional curved surface technology, applied in manufacturing tools, laser welding equipment, metal processing equipment, etc., can solve the problems of sensor accuracy decline, time-consuming, processing efficiency, and processing accuracy 3D curved surface adaptability needs to be improved. The effect of machining efficiency and improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

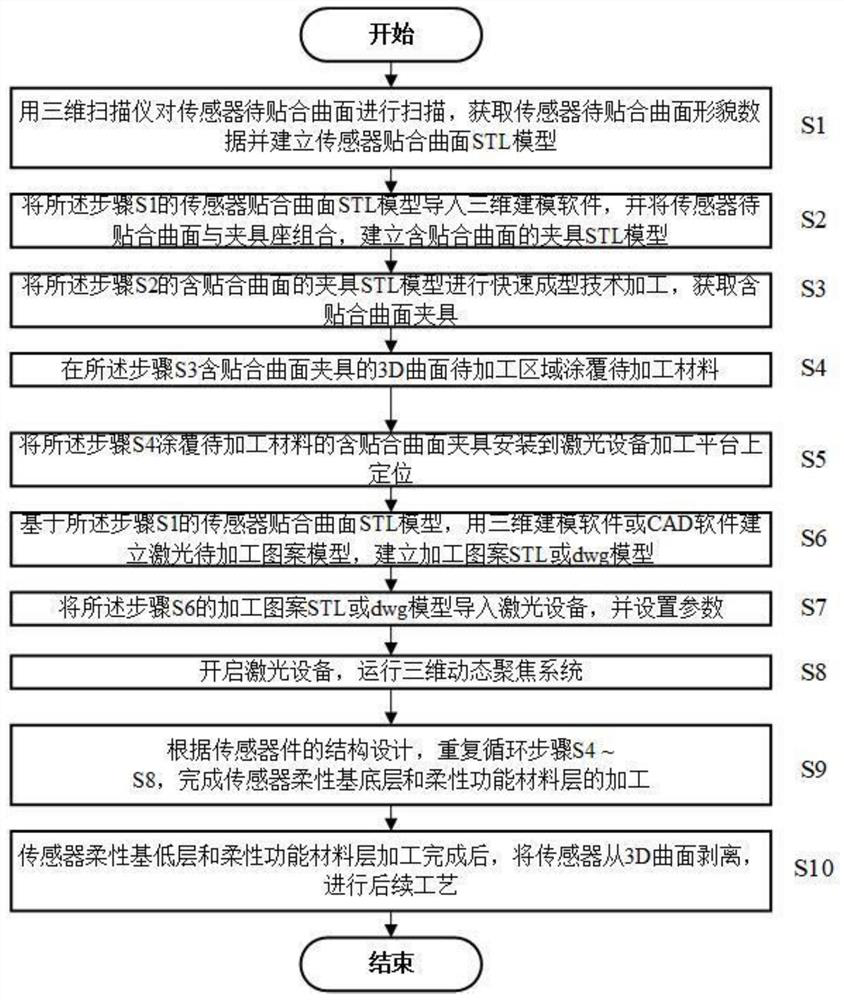

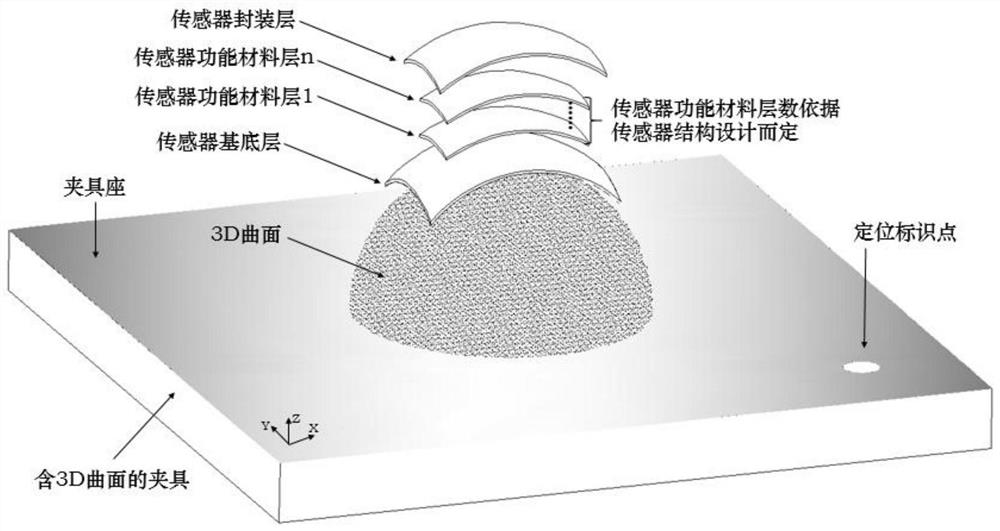

[0033] Attached below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 And embodiment, the present invention is described in further detail, and concrete steps include:

[0034] When monitoring data, many sensors need to fit well to the area to be monitored, but when the area to be monitored is a 3D curved surface, the sensors cannot fit well. The processed flexible sensor is perfectly fitted to the 3D curved surface to be fitted, and is not limited by the curvature of the curved surface, and the 3D curved surface splicing process is not performed after the 2D plane is processed.

[0035] Step 1: Scan the surface to be attached to the sensor with a 3D scanner, obtain the topography data of the surface to be attached to the sensor, and establish an STL model of the surface to be attached to the sensor.

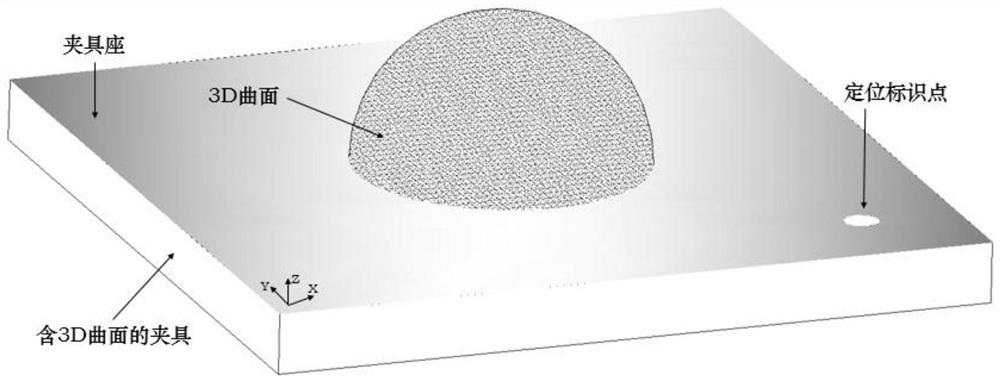

[0036] Step 2: Import the STL model of the sensor fitting surface of the step 1 into the three-dimensional modeling software, and combine the sensor surface to be f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com