Detection planning method based on quality function allocation

A quality and planning technology, applied in the field of quality inspection planning based on quality function configuration, can solve problems such as the lack of quantitative description methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The present invention will be described in further detail below in conjunction with the accompanying drawings.

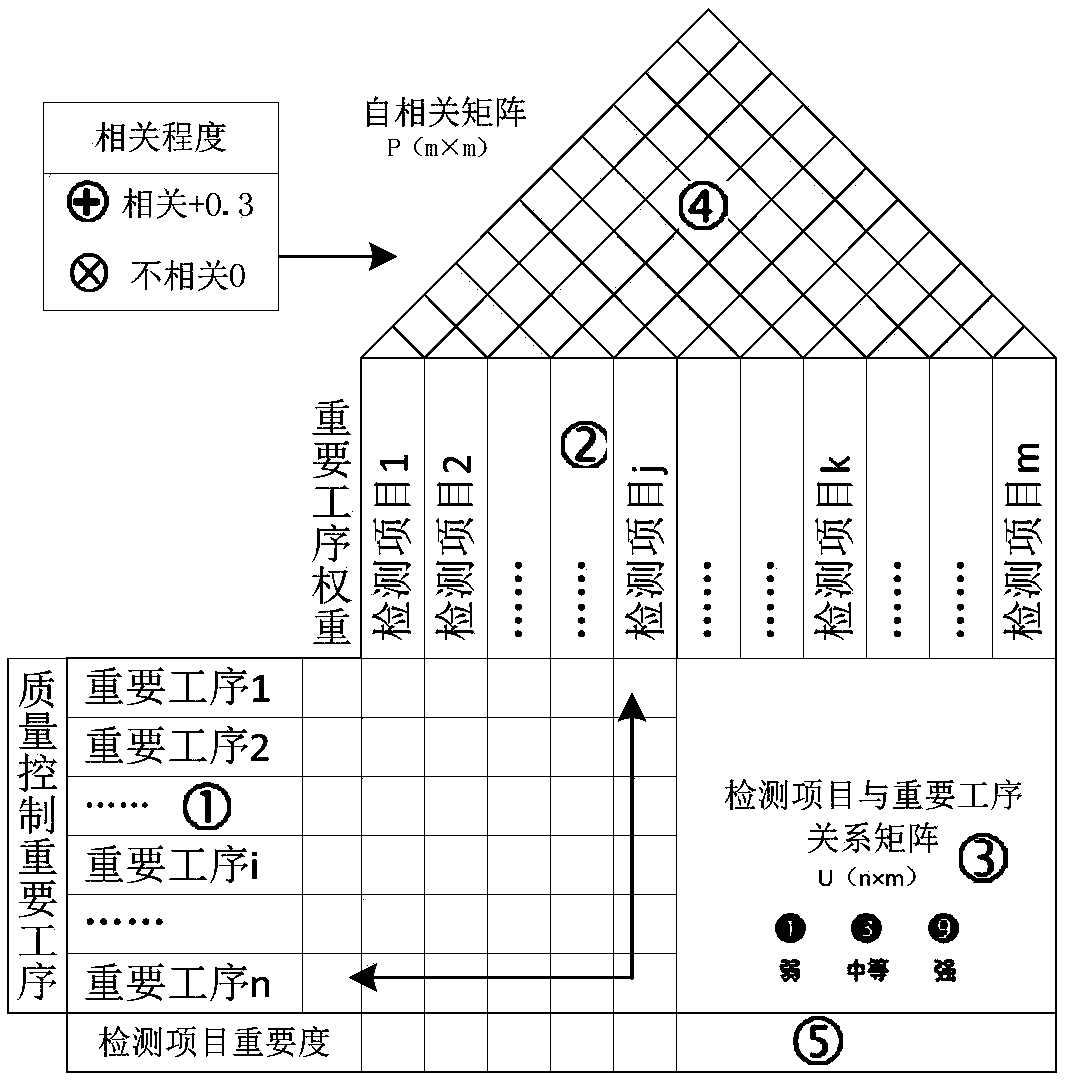

[0080] Quality Function Deployment (QFD) in the design of the present invention is initially a new product development and quality assurance technology formed to meet customer needs, improve product quality and win market competition. The quality function configuration takes the customer's quality requirements as input to drive product planning and design, and at the same time obtains quality characteristics that have a greater impact on customer needs through quantitative calculations, so as to facilitate product quality control.

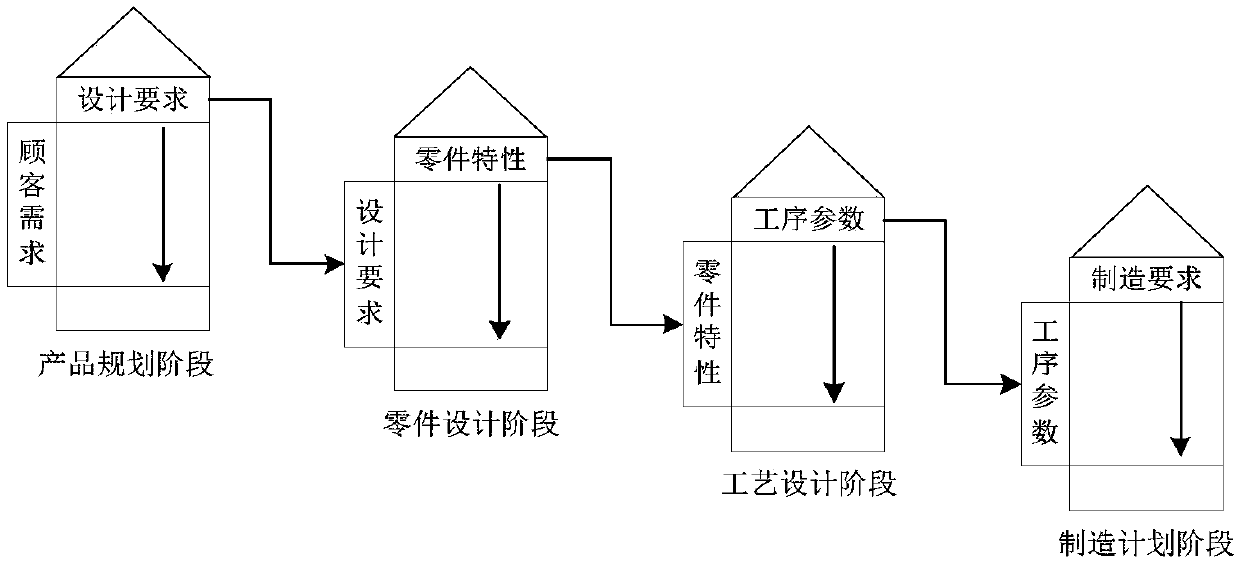

[0081] Since the four stages of the American Suppliers Institute (ASI) model: component planning, component design, process design, and production planning correspond to the general product development process of enterprises, it has been widely used by scholars and enterprises. The specific process of its four-stage decomposition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com