A safety prevention and control method and device for a battery energy storage module

A battery energy storage and battery technology, which is applied to batteries, secondary batteries, battery pack components, etc., can solve the problems of high cost and poor thermal pick-up effect of battery energy storage modules, so as to protect safety and suppress the spread of flames. , reduce the effect of safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

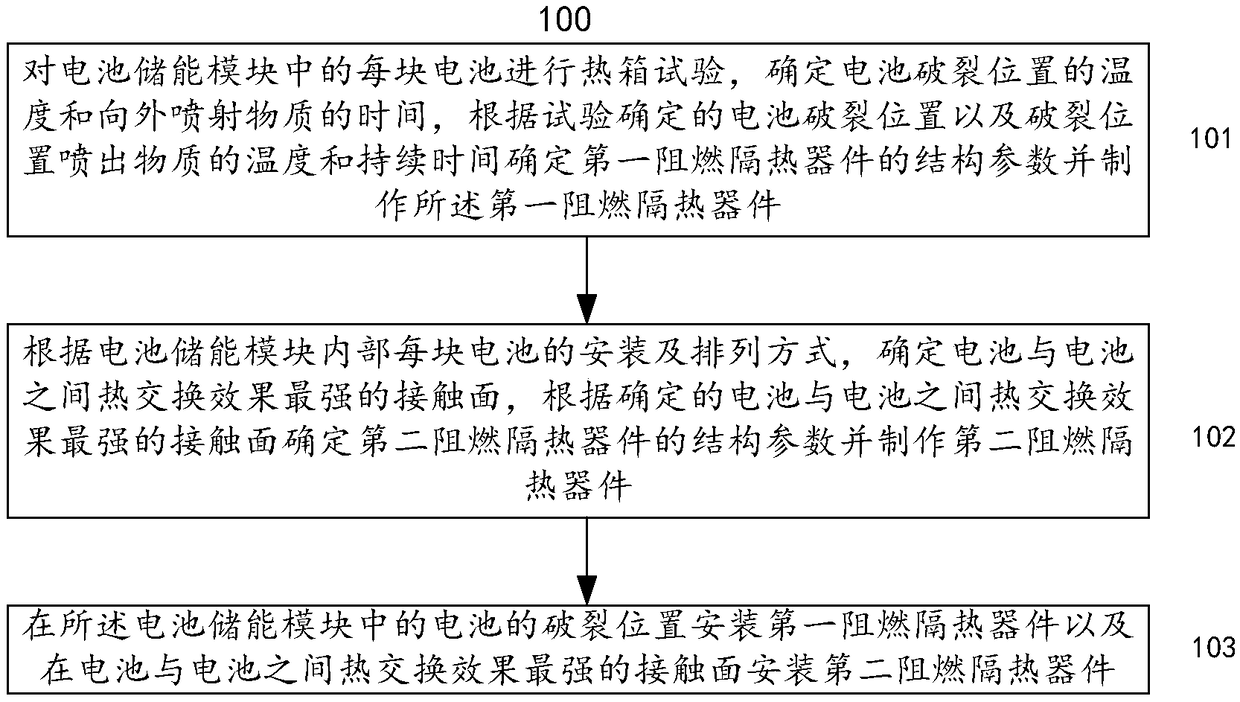

[0052] figure 1 It is a flow chart of the safety prevention and control method of the battery energy storage module according to the first preferred embodiment of the present invention. Such as figure 1 As shown, this preferred embodiment is to design and prepare a flame-retardant and heat-insulating device for a hard-shell packaged lithium-ion battery module. Explosion-proof valve, the cooling method of the battery module is air cooling. The safety prevention and control method 100 for battery energy storage modules in this preferred embodiment starts from step 101 .

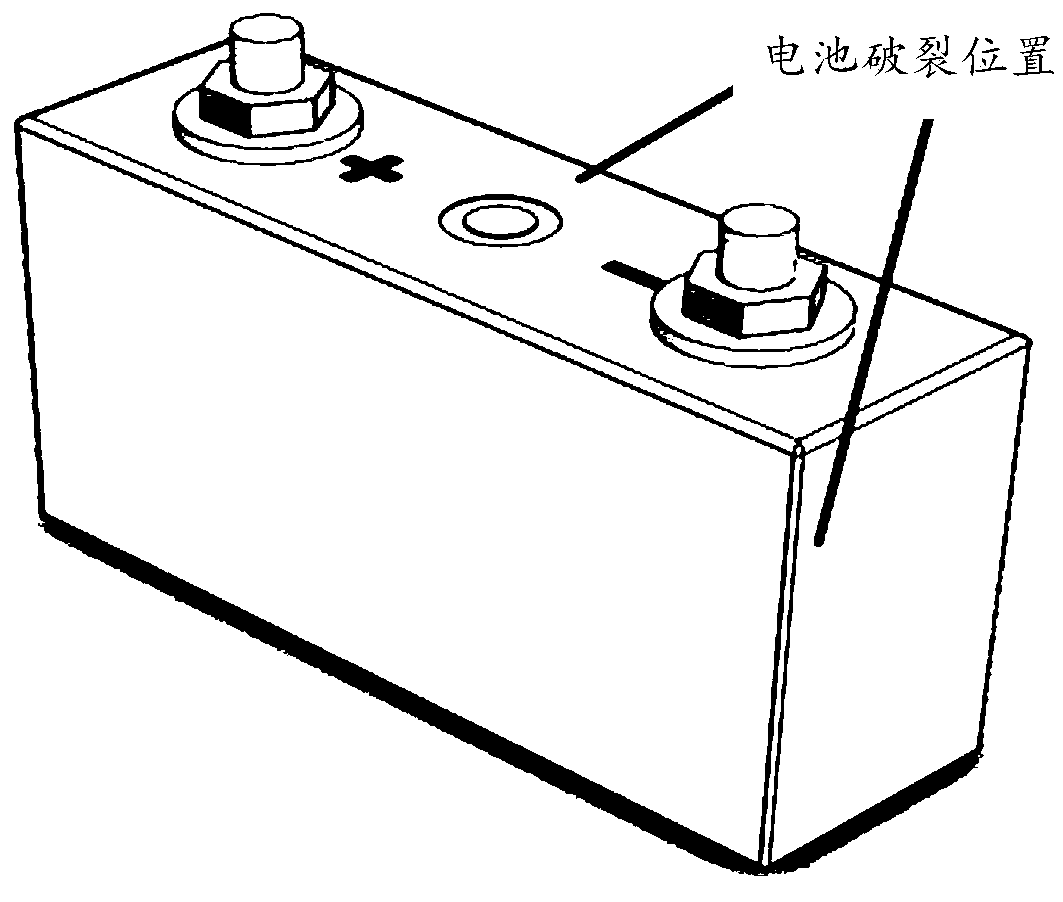

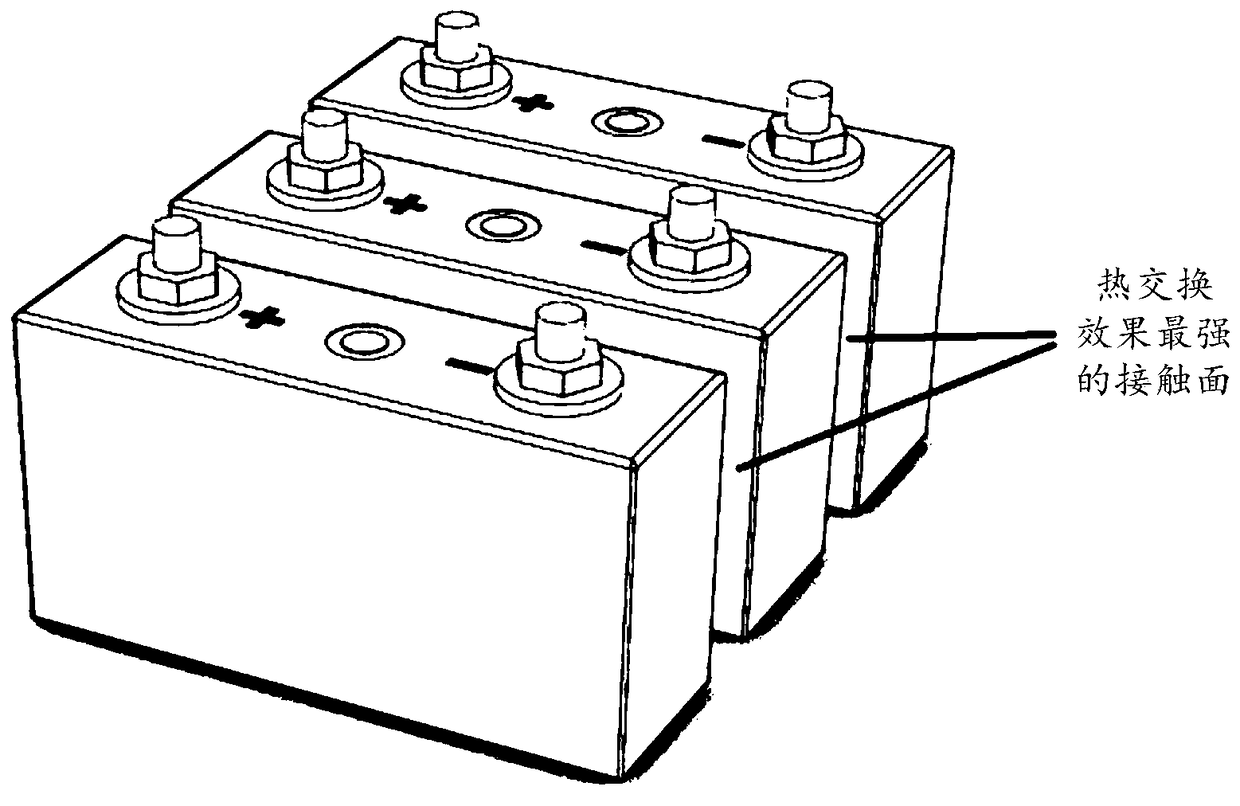

[0053] In step 101, test the battery in the battery energy storage module, determine the rupture location of the battery and the temperature and duration of the substance ejected from the rupture location of the battery, and determine the rupture location of the battery and the temperature of the substance ejected from the rupture location according to the test and duration to determine the structural parame...

Embodiment 2

[0097] Figure 8 It is a flow chart of the safety prevention and control method of the battery energy storage module according to the second preferred embodiment of the present invention. Such as Figure 8 As shown, this preferred embodiment is to design and prepare a safety protection device for a hard-shell packaged lithium-ion battery module. The cooling method of the module is air cooling. The safety prevention and control method 800 of the battery energy storage module in this preferred embodiment starts from step 801 .

[0098] In step 801, conduct a hot box test on each battery in the battery energy storage module, heat the battery at a heating rate of 20°C / min until the battery ruptures, and determine the temperature at the ruptured location of the battery and the time for ejecting substances.

[0099] Figure 9 It is a schematic diagram of the rupture position of the battery in the battery energy storage module of the second preferred embodiment of the present inv...

Embodiment 3

[0118] Figure 12 It is a flow chart of the safety prevention and control method of the battery energy storage module according to the third preferred embodiment of the present invention. Such as Figure 12 As shown, this preferred embodiment is to design and prepare a safety protection device for a soft-packed lithium-ion battery module, the battery is soft-packaged, the battery has a nominal capacity of 10Ah, the battery lugs are drawn out from the same side, and the cooling method of the battery module is liquid cooling. The safety prevention and control method 1200 of the battery energy storage module in this preferred embodiment starts from step 1201 .

[0119] In step 1201, conduct a hot box test on each battery in the battery energy storage module at a heating rate of 1°C / min, heat until the battery ruptures, determine the location of the battery rupture, the temperature of the rupture location, and the time for ejecting substances.

[0120] Figure 13 It is a schema...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com