Phase-change heat-storage energy-saving electric water heater

A phase-change heat storage and electric water heater technology, which is applied to water heaters, fluid heaters, heat exchange materials, etc., can solve the problems of inconspicuous energy-saving advantages, low heating water efficiency, and inconspicuous energy-saving, etc., to reduce energy consumption Low energy consumption, high heat utilization efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

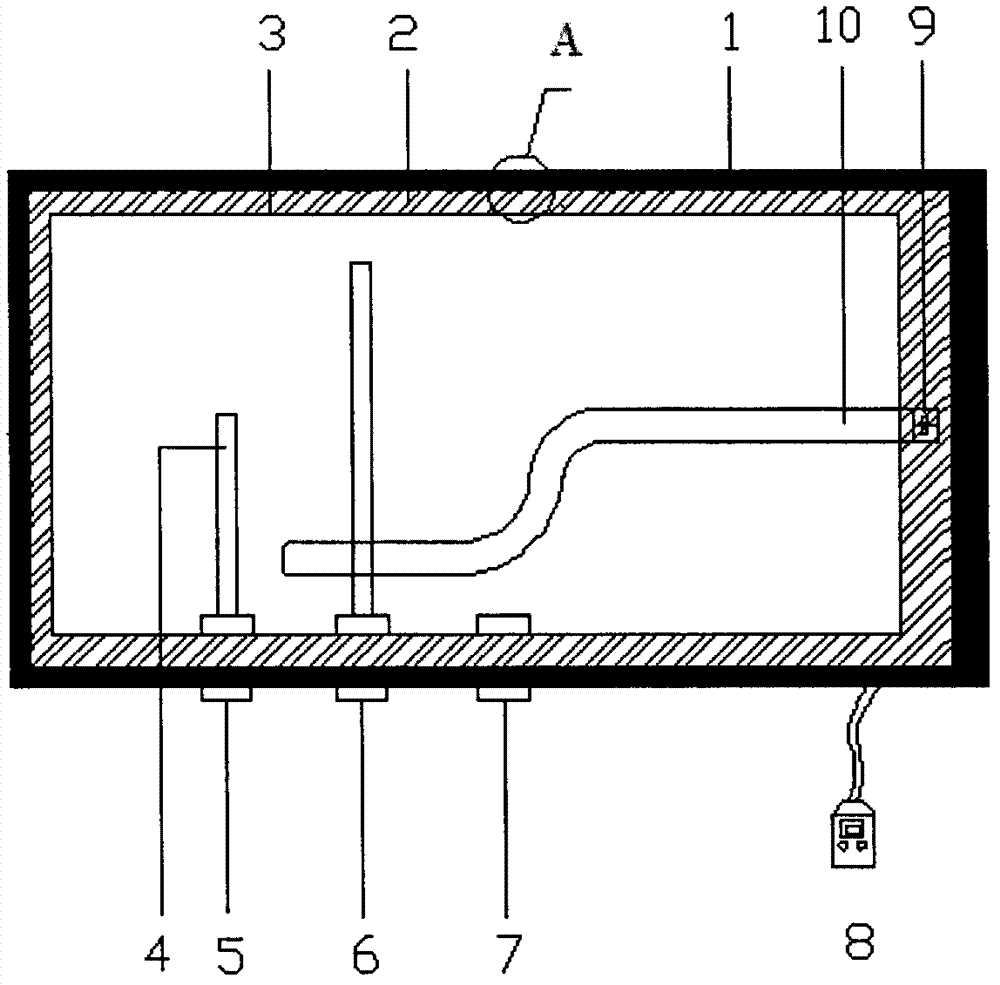

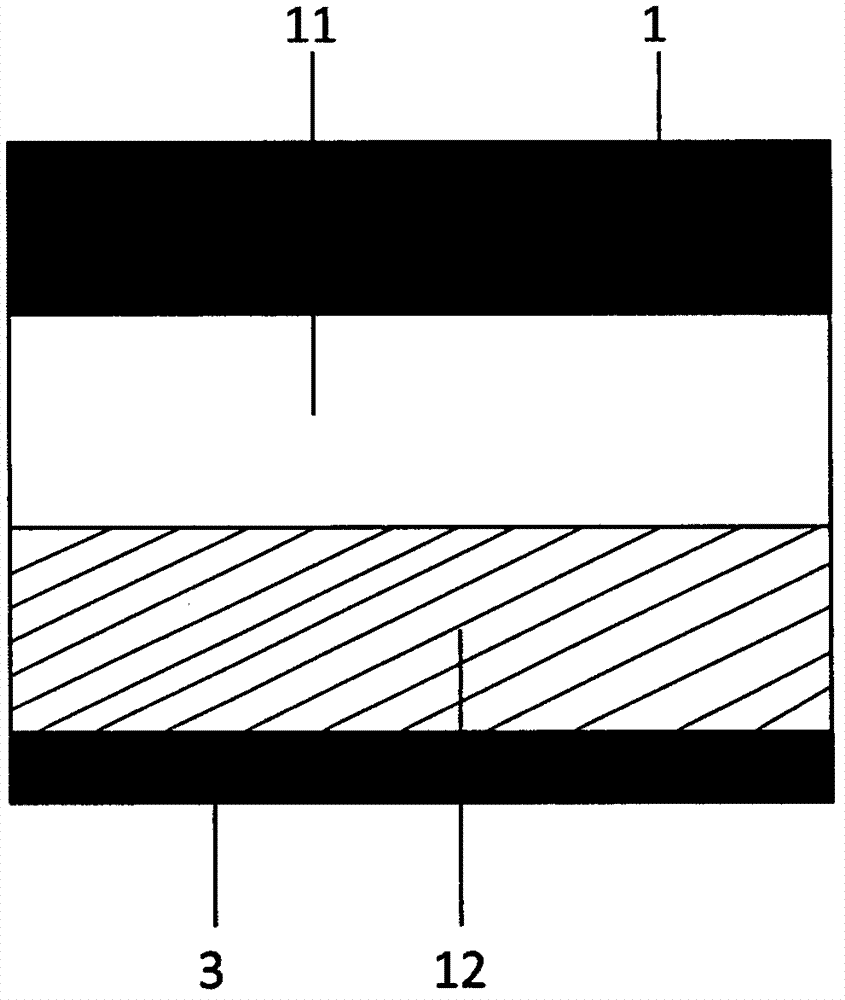

example 1

[0016] In a storage-type electric water heater with a capacity of 40L (the inner diameter of the water tank is 0.336m, and the length of the cylinder is 0.50m), a composite insulation layer containing phase change materials is used, and the thickness is 0.045m. The phase change material is n-octadecane, the phase change temperature is 62.8°C, the phase change enthalpy is 244J / g, and the density is 0.910g / m 3 , the phase change heat storage layer is made by macro capsule technology, and it is placed close to the outside of the liner, with a thickness of 0.019m. The polyurethane foam heat insulation layer is prepared by integral foaming technology, which is filled with the gap between the phase change heat storage layer and the shell, and the thickness is 0.026m, that is, the thickness ratio of the phase change heat storage layer to the polyurethane foam heat insulation layer is 0.73. The water heater was tested in accordance with the relevant test conditions stipulated in the "...

example 2

[0018] In a storage-type electric water heater with a capacity of 50L (the inner diameter of the water tank is 0.336m, and the length of the cylinder is 0.605m), a composite insulation layer containing phase change materials is used, and the thickness is 0.035m. The phase change material is 1-hexadecanoic acid, the phase change temperature is 64°C, the phase change enthalpy is 200J / g, and the density is 0.850g / m 3 , the phase-change heat storage layer is made by macrocapsule technology, and it is placed close to the outside of the liner with a thickness of 0.015m. The polyurethane foam heat insulation layer is prepared by integral foaming technology, which is filled with the gap between the phase change heat storage layer and the shell, and the thickness is 0.020m, that is, the thickness ratio of the phase change heat storage layer to the polyurethane foam heat insulation layer is 0.75. The water heater was tested according to the relevant test conditions described in Example ...

example 3

[0020] In a storage-type electric water heater with a capacity of 60L (the inner diameter of the water tank is 0.336m, and the length of the cylinder is 0.71m), a composite insulation layer containing phase change materials is used, and the thickness is 0.035m. Among them, the phase change material is n-triundecane, the phase change temperature is 65°C, the phase change enthalpy is 252J / g, and the density is 0.910g / m 3 , the phase change heat storage layer is made by macro capsule technology, and it is placed close to the outside of the liner, with a thickness of 0.013m. The polyurethane foam heat insulation layer is prepared by integral foaming technology, which is filled with the gap between the phase change heat storage layer and the shell, and the thickness is 0.022m, that is, the thickness ratio of the phase change heat storage layer to the polyurethane foam heat insulation layer is 0.59. The water heater was tested according to the relevant test conditions described in E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com