Back-flushing type dirt separator with continuous vibration function for pipeline cleaning

A kind of pipeline cleaning and continuous technology, which can be used in fixed filter element filters, chemical instruments and methods, filtration and separation, etc., can solve the problems of clogging pipelines and affecting filtration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

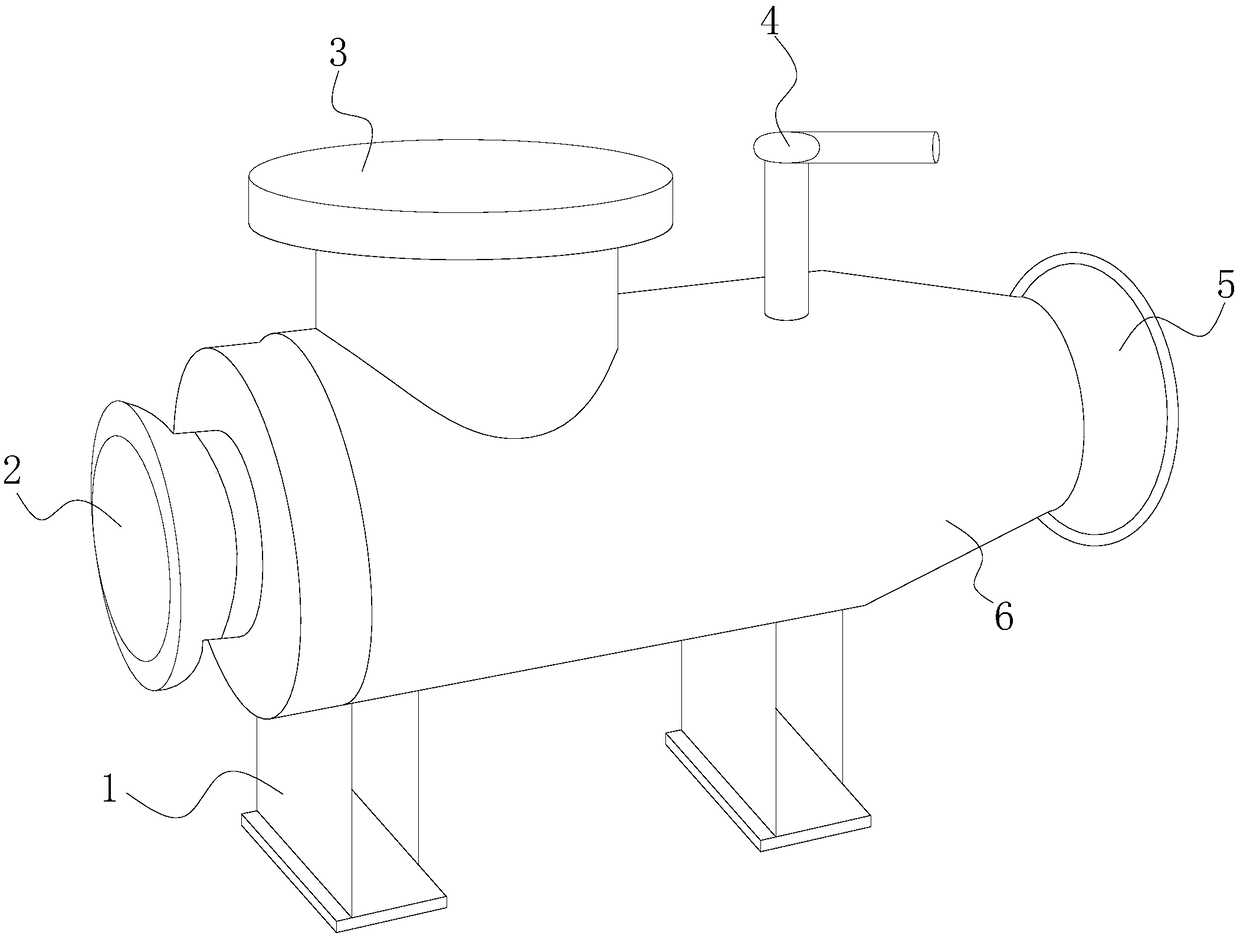

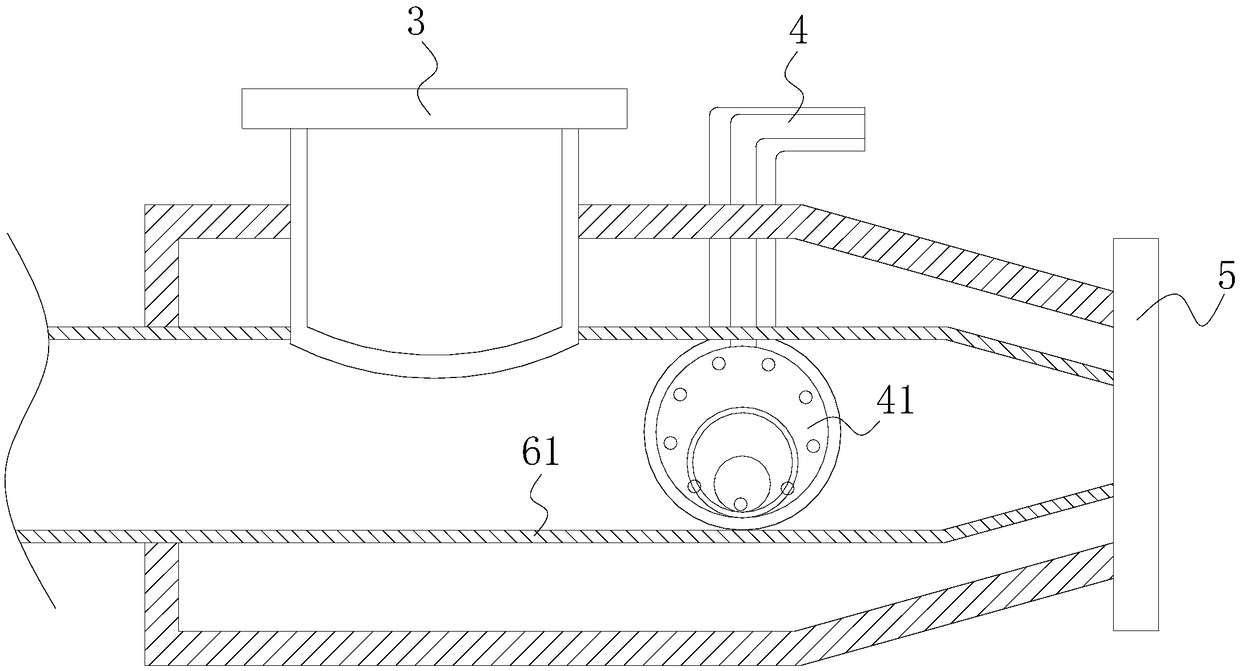

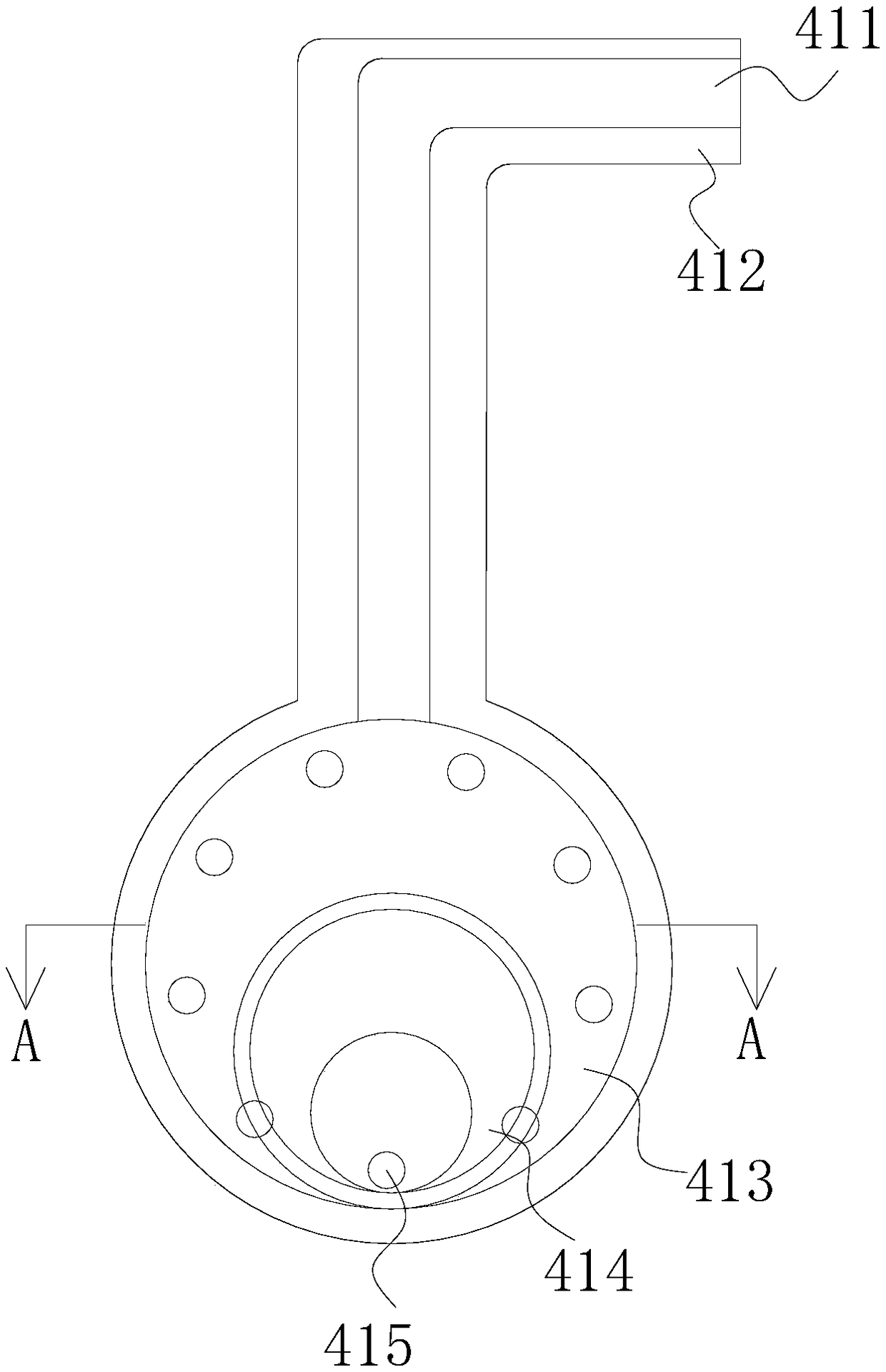

[0021] Such as Figure 1-Figure 2 As shown, the present invention provides a backwash type decontamination device for sustainable vibration of pipeline cleaning, its structure includes a support foot 1, a water inlet 2, a sewage outlet 3, an air valve 4, a water outlet 5, and a body 6. The inside of the body 6 is provided with a filter screen 61, the body 6 is horizontal, and an integrated water inlet 2 and a water outlet 5 are respectively provided at its head and tail, and the supporting legs 1 are provided with two and vertically fixed on the body 6, the sewage outlet 3 and the body 6 are integrated above it and are located on the same level as the air valve 4, and the air valve 4 runs through the end of the body 6 with a high-frequency vibrator 41, the high The frequency vibrator 41 is arranged inside the filter screen 61, and the diameters of the two are equal. The filter screen 61 and the sewage outlet 3 are welded together through one end of the body 6, and the end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com