Electrolyte preparation equipment and method

An electrolyte and equipment technology, applied in the field of electrolyte preparation equipment, can solve the problems of filter plate clogging, poor stirring effect, affecting the quality of electrolyte, etc., and achieve the effect of preventing clogging and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

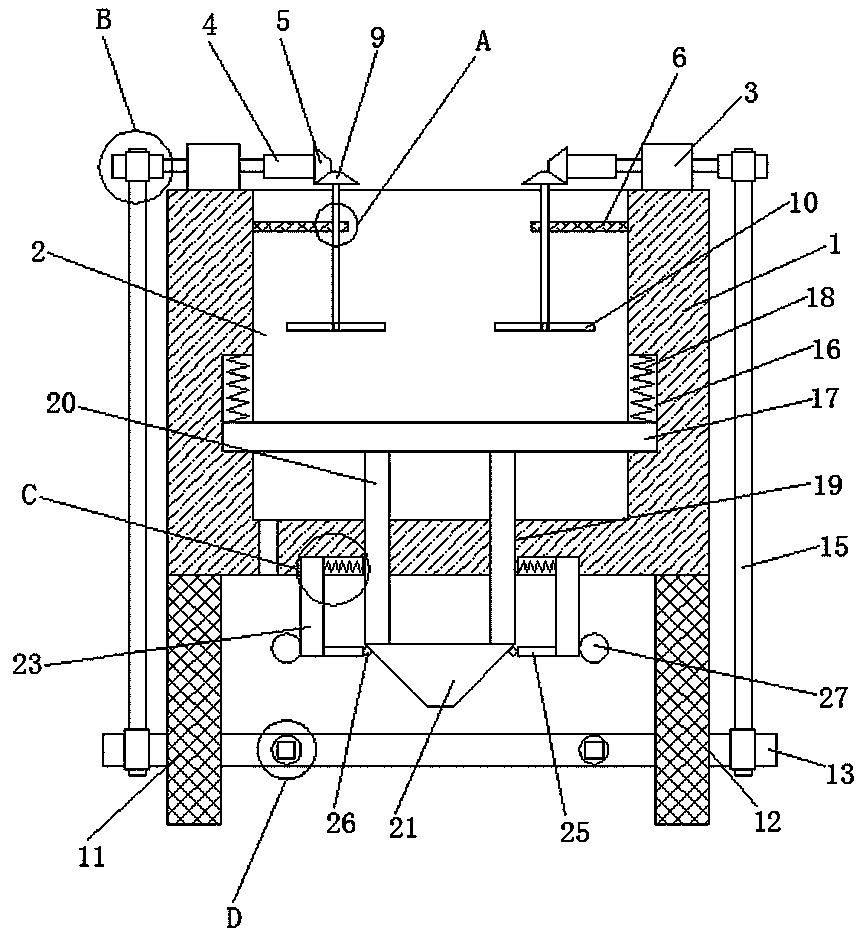

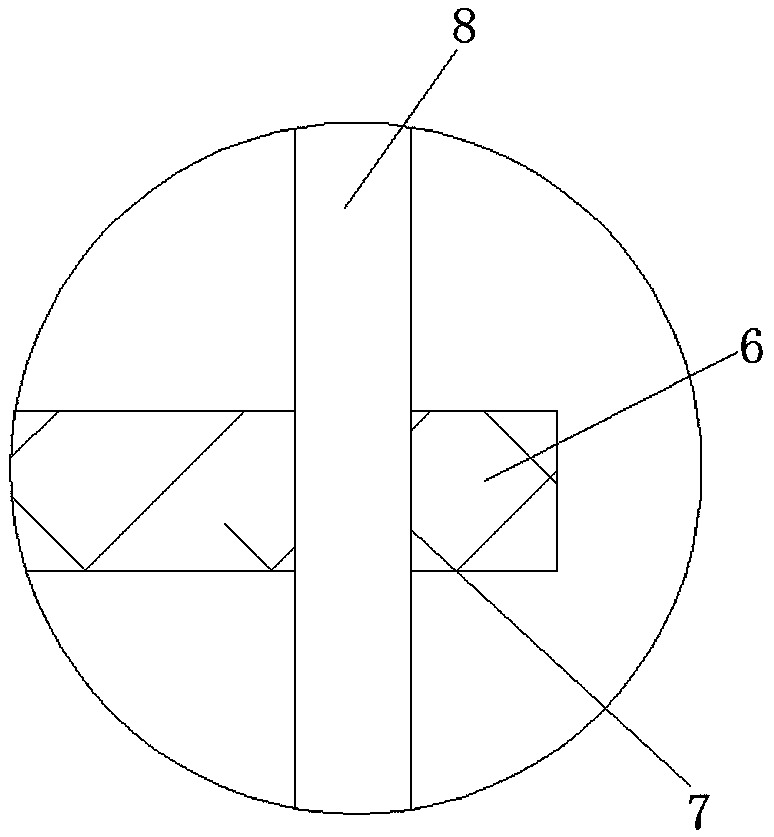

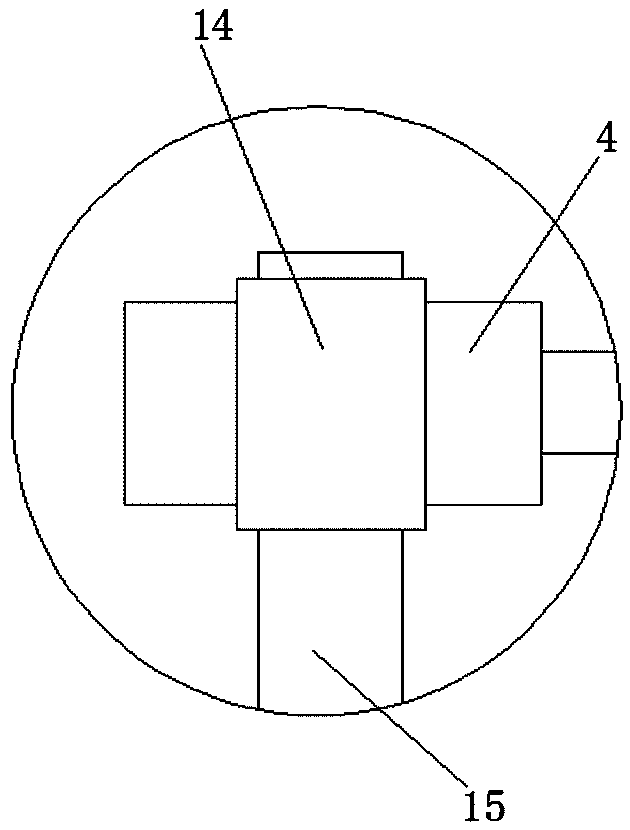

[0030] refer to Figure 1-5In this embodiment, a kind of electrolyte preparation equipment is proposed, comprising a preparation box 1, a preparation tank 2 is provided on the top of the preparation box 1, and a biaxial stirring motor 3 is fixedly installed on both sides of the top of the preparation box 1, and the biaxial stirring The output shaft of the motor 3 is welded with a stirring shaft 4, and the ends of the two stirring shafts 4 between the two biaxial stirring motors 3 that are close to each other are welded with a first bevel gear 5. The traction plate 6 is welded, and the top of the traction plate 6 is provided with a traction hole 7, and the rotation shaft 8 is installed in the traction hole 7. The top of the rotation shaft 8 is welded with a second bevel gear 9, and the outer side of the rotation shaft 8 is welded with a plurality of The rotating rod 10 is welded with support plates 11 on both sides of the bottom of the preparation box 1, and the support plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com