Advanced multi-color jelly production equipment

A technology for producing equipment and jelly, which is applied to mixers with rotating containers, dissolving machines, mixers, etc., can solve the problems of single setting mode, low stirring efficiency, poor stirring effect, etc., achieves easy replacement operation, improves stirring effect, The effect of improving mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

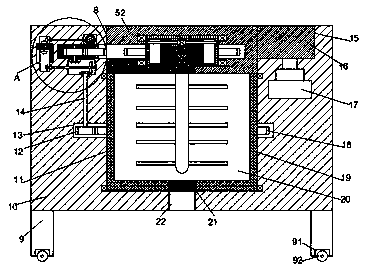

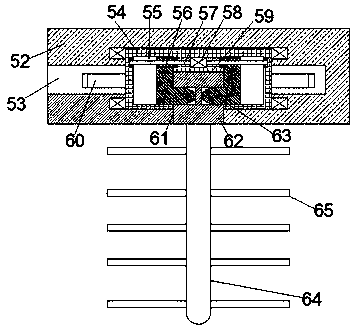

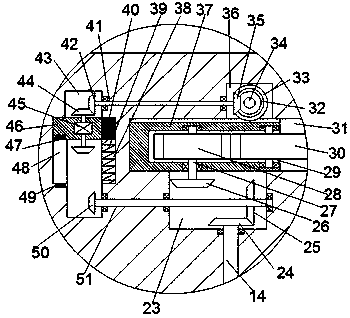

[0023] Such as Figure 1-3As shown, a kind of advanced multi-color jelly production equipment of the present invention comprises the placement frame 10 that is fixedly arranged on the angle frame 9 and the stirring structure that is arranged in the described placement frame 10, and the described placement frame 10 is provided with the first A rotary bin 11, the inner top wall of the first rotary bin 11 is provided with a first communication groove 8 connected to the outside, and a second rotary bin that runs through the first rotary bin 11 extends from left to right in the placement frame 10 13. A stirring box 19 is rotatably installed in the first rotary bin 11 through a bearing, and the outer surface of the stirring box 19 is fixedly provided with an outer ring gear 18 extending into the second rotary bin 13 in the peripheral direction, so A first sliding chamber 31 is provided extending leftward in the left end wall of the first communication groove 8, and a sliding push bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com