Guide blade angle linkage adjusting device

A technology of guide vanes and adjustment devices, which is applied in the direction of separating solids from solids by air flow, solid separation, grain processing, etc., and can solve the problems of poor consistency of guide vane angles, time-consuming and laborious, difficult disassembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, this technology is further described:

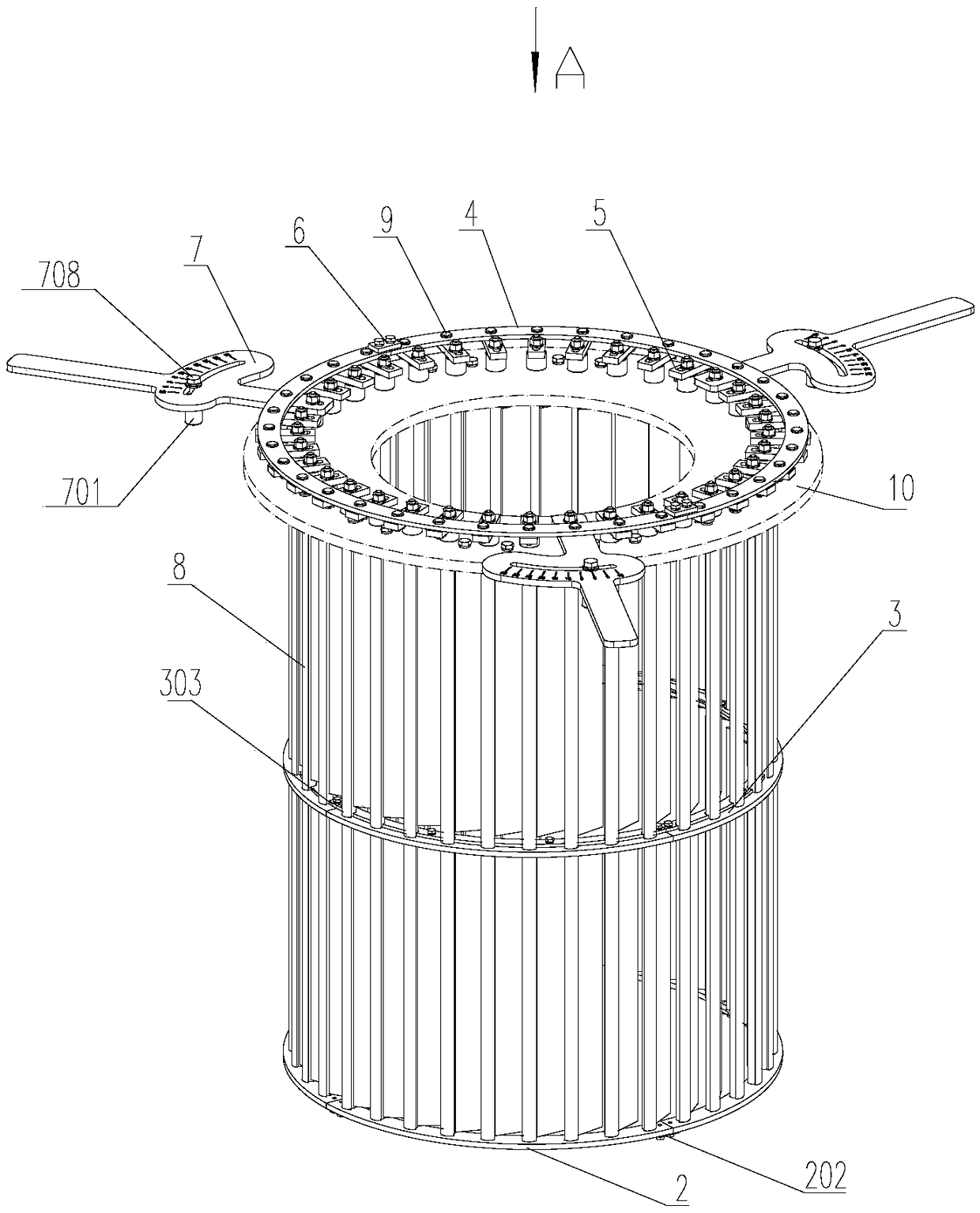

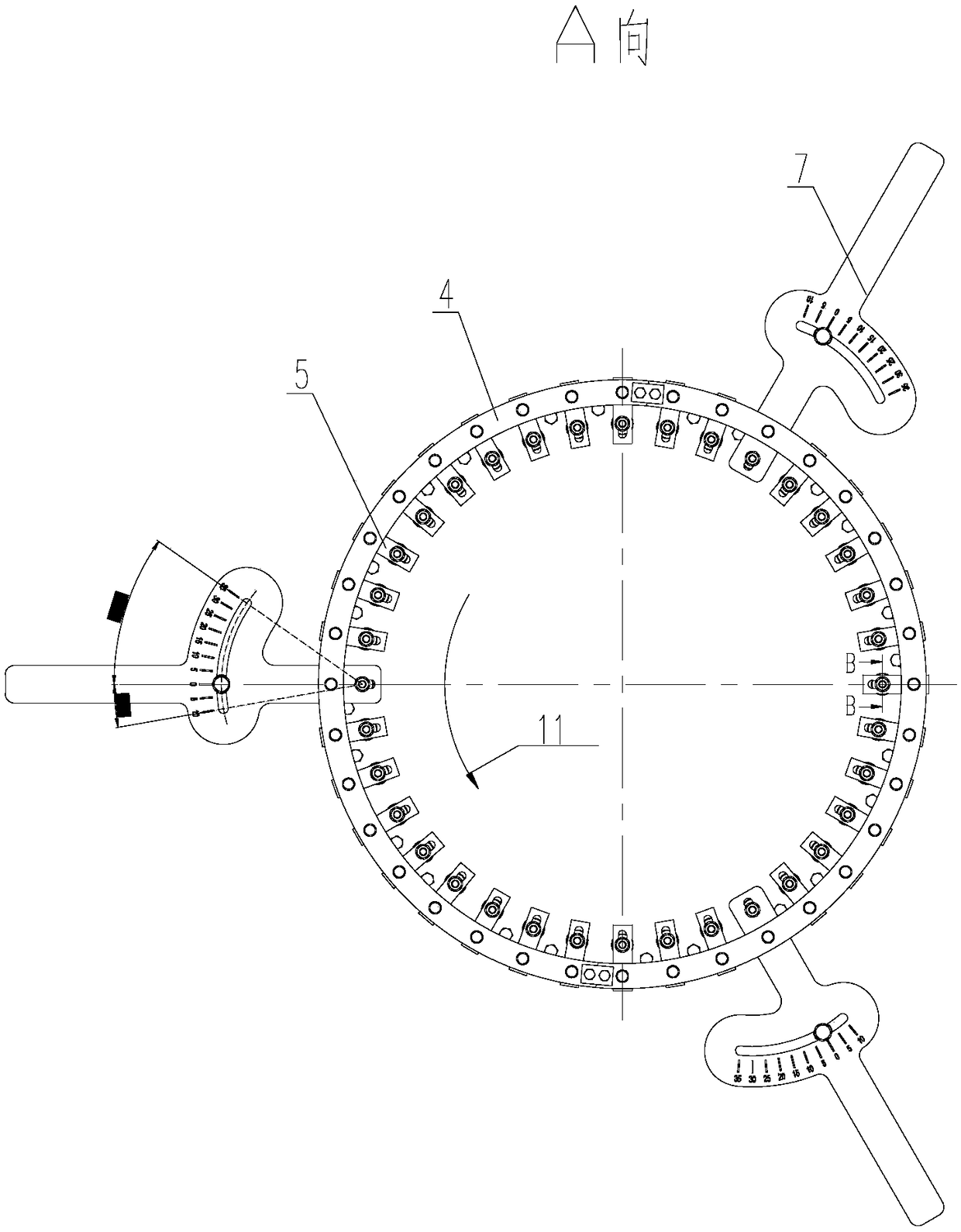

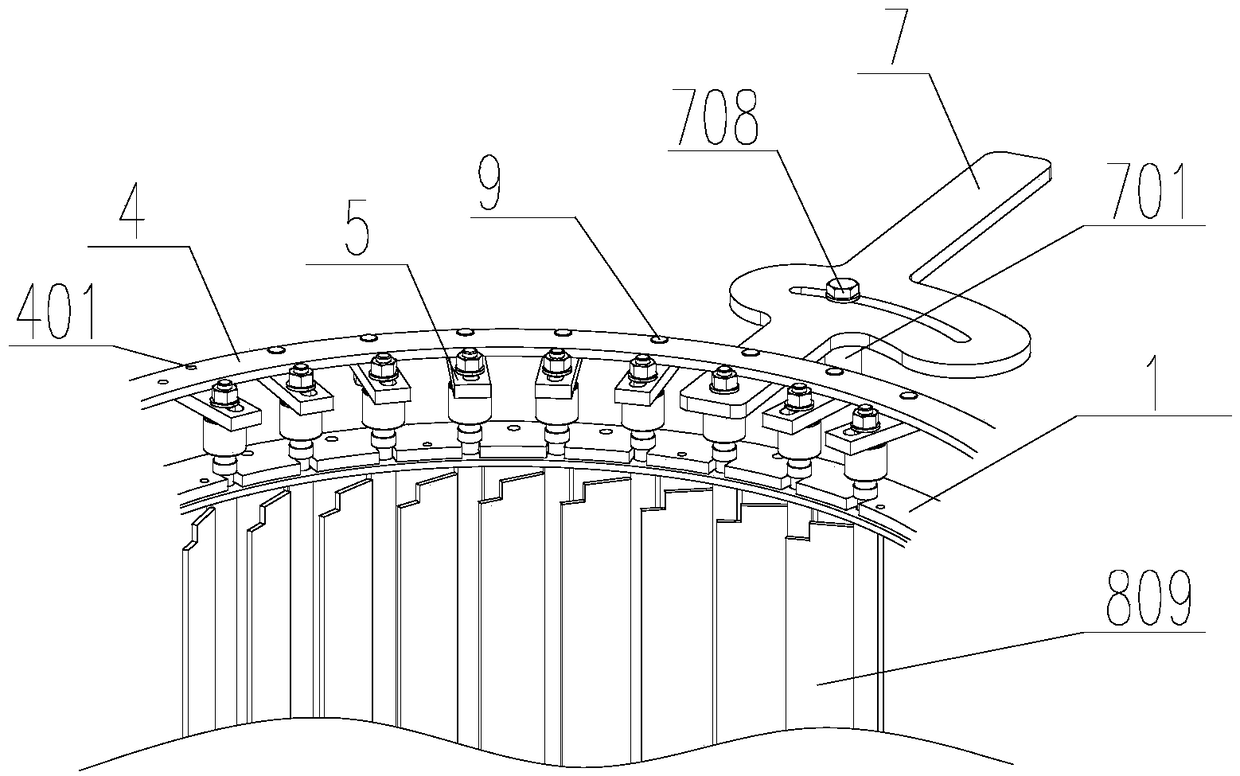

[0031] see Figure 1-Figure 5 The shown guide vane angle linkage adjustment device includes a guide vane assembly fixedly connected to the frame, the guide vane assembly includes a guide vane and a guide vane bracket, and the guide vane bracket includes at least the The upper flange and the lower flange located below and parallel to the upper flange, a group of guide vanes are evenly distributed along the circumference of the guide vane bracket, and are swingably arranged on the guide vane bracket; The straight plate connected to the rotating shaft, the rotating shaft swings and is set on the upper flange and the lower flange; the part of the shaft head protruding from the outer flange of the rotating shaft is used to connect the guide vane assembly with the frame from bottom to top. part, the supporting part used to cooperate with the upper flange to provide fixed support for the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com