Grinder fixture for precise and efficient grinding of injection needle tip and operation method thereof

A technology of injection needles and grinding machines, which is applied in the direction of machine tools, grinding machines, and manufacturing tools suitable for grinding the edge of workpieces, and can solve limited and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

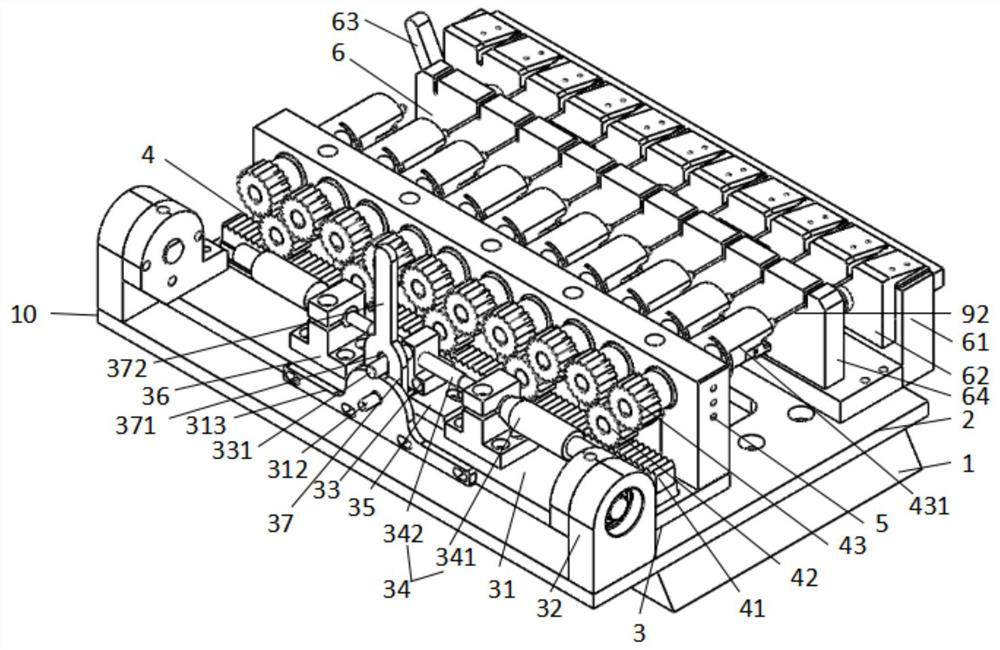

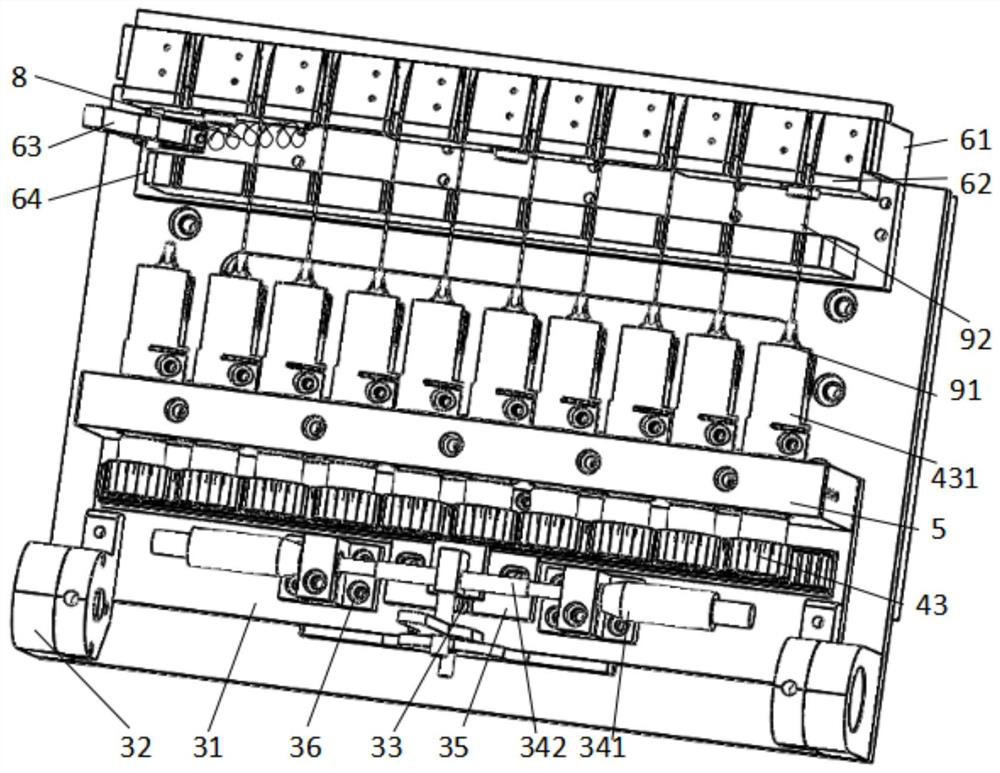

[0030] Embodiments of the present invention will be further described below in conjunction with specific implementation manners, and examples of the embodiments are shown in the accompanying drawings.

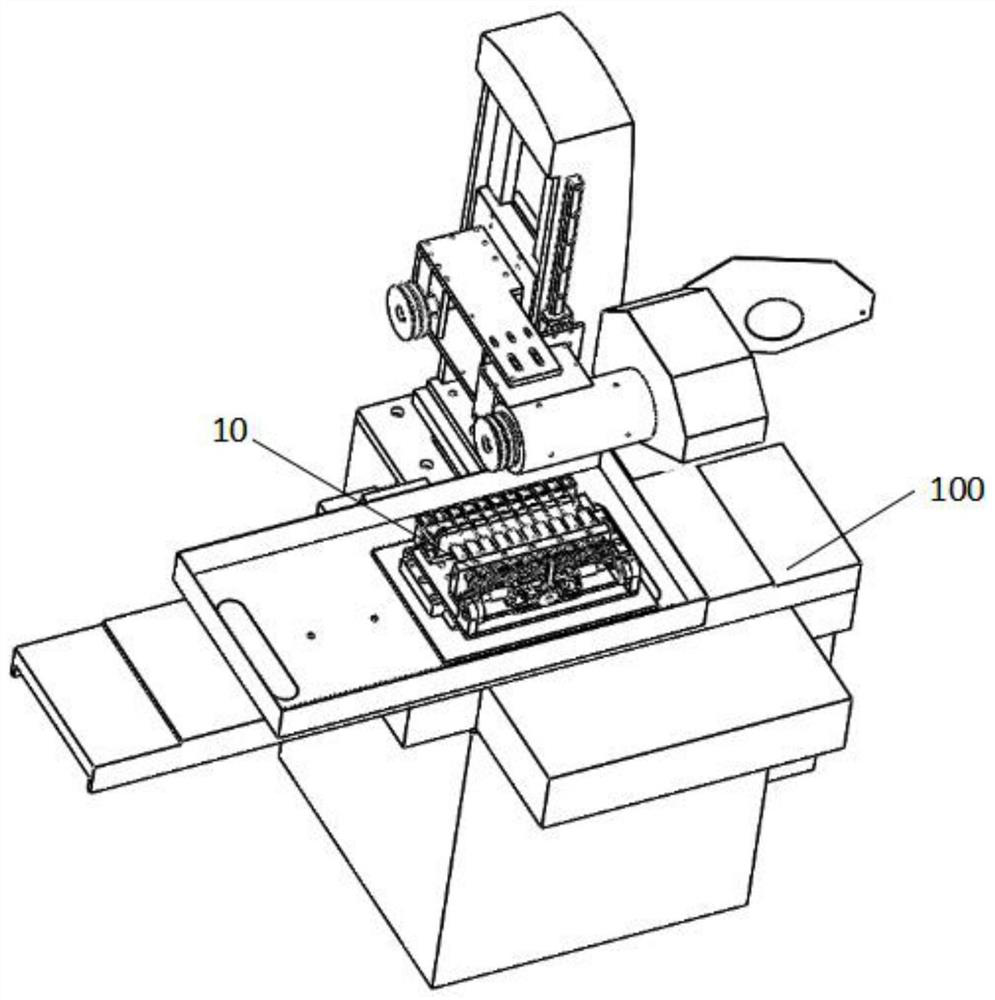

[0031] Such as Figure 1-7 , a grinder jig 10 for precise and efficient grinding of injection needle points, installed on a grinder 100, and used for grinding a row of needle heads 9 at the same time after rotating the angle, and the injection needle heads 9 include a needle seat 91 and an injection needle 92, including a mounting plate 1, Bottom plate 2 and the adjustment mechanism 3, the transmission mechanism 4, the middle plate 5, and the matching mechanism 6 arranged on the bottom plate 2, the installation plate 1 is used to install the jig on the grinding machine 100, and the front end of the bottom plate 2 is provided with the adjustment mechanism 3 , the adjustment mechanism 3 includes a flip plate 31, a flip shaft seat 32, a fixed block 36, a regulator 34, a backing pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com