Glass stamping machine

A technology of embossing machine and glass, applied in printing machine, rotary printing machine, printing, etc., to achieve the effect of fine pattern, improved printing effect and high pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0028] The "front", "rear", "left" and "right" orientations mentioned in this application all refer to the moving direction of the mobile carrier.

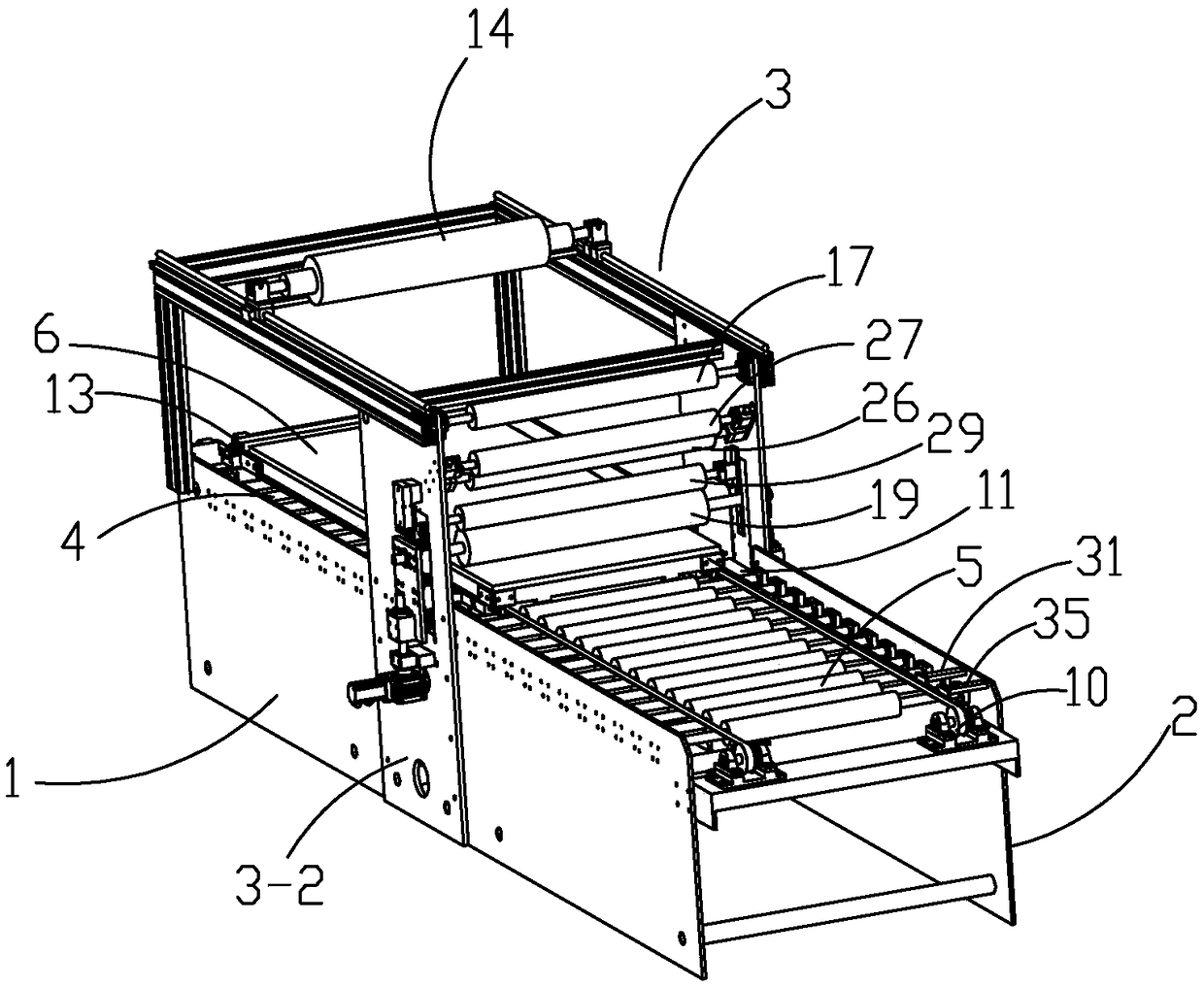

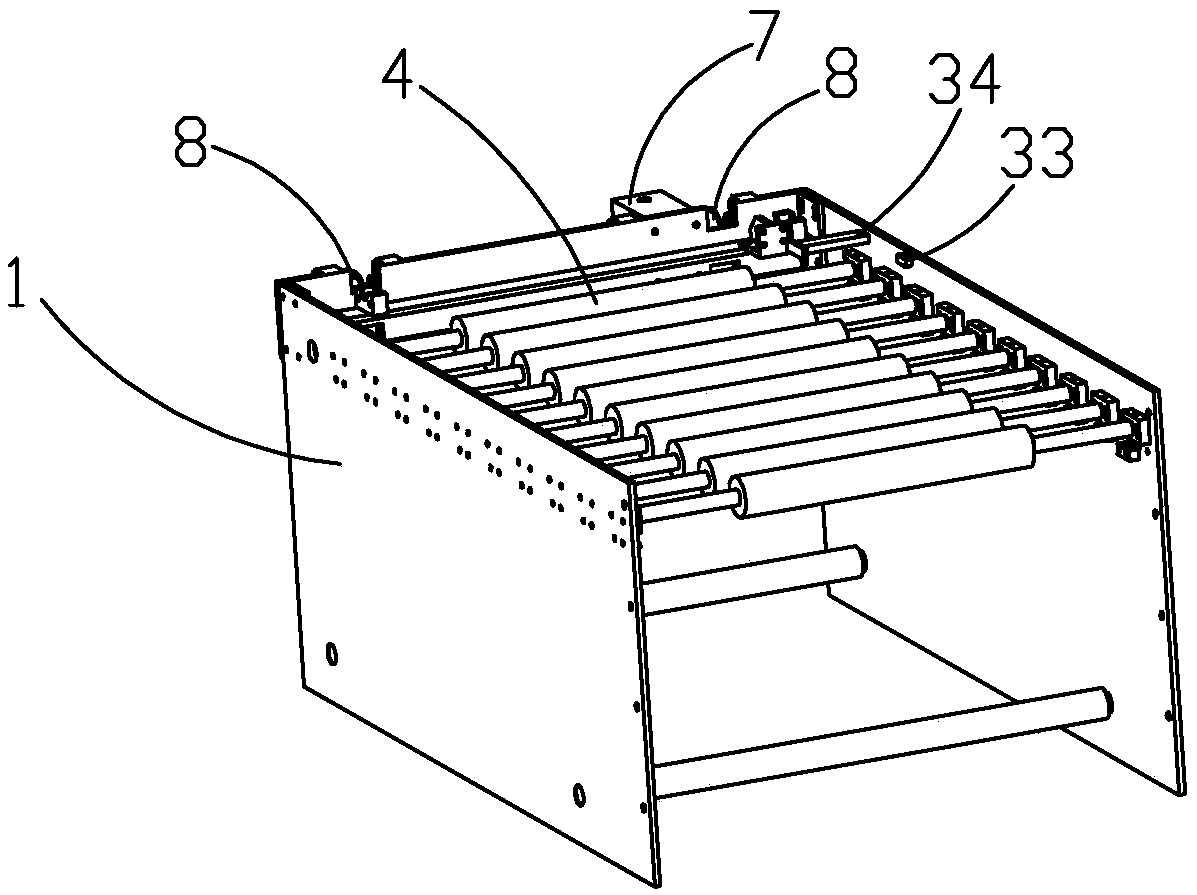

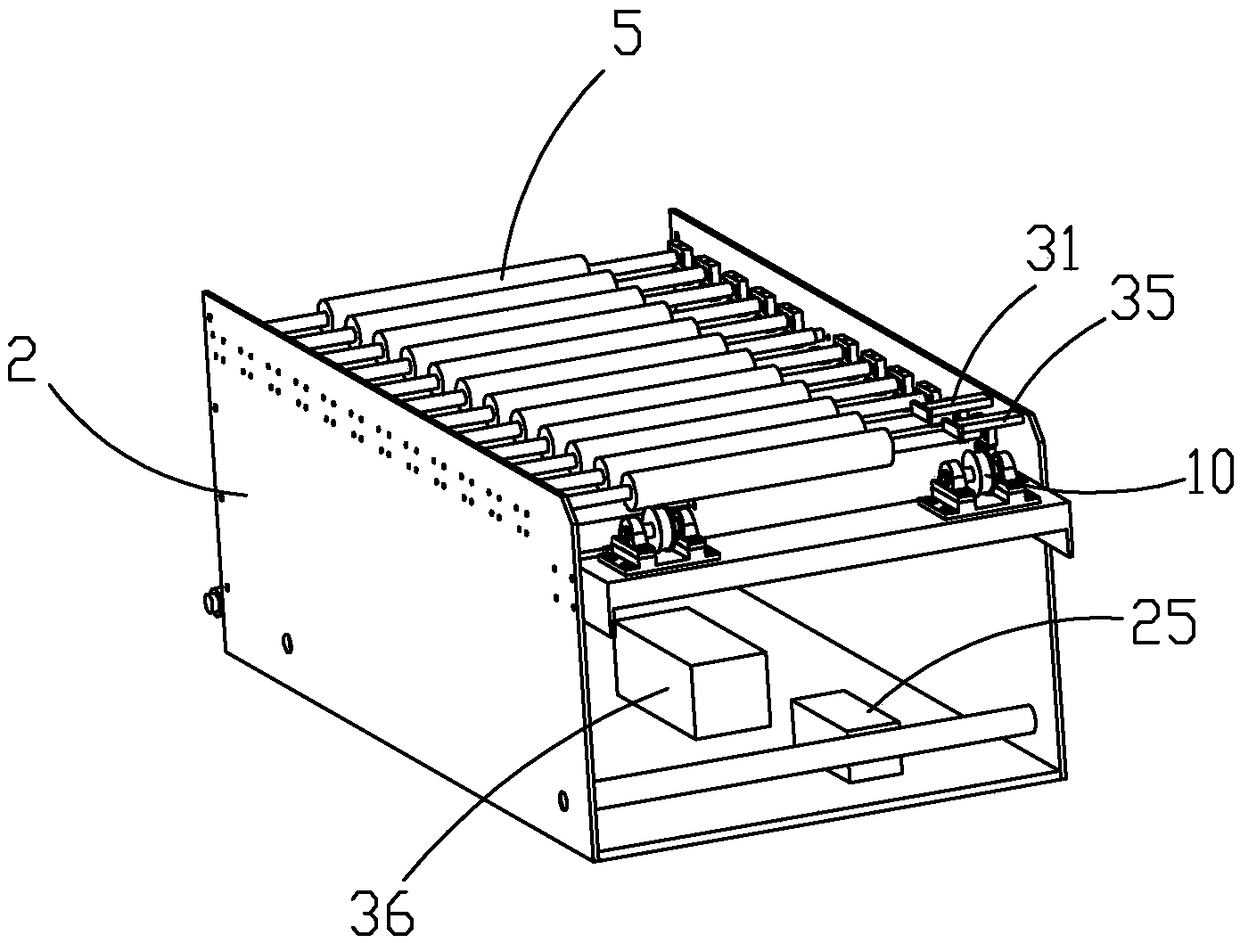

[0029] refer to Figure 1-7 :

[0030] A glass embossing machine, comprising an embossing table 1, an introduction table 2 and an embossing frame 3, the embossing table 2 is provided with a first horizontal roller line 4, and the introduction table 1 is provided with a butt joint with the first horizontal roller line 4 The second horizontal drum line 5 and the embossing frame 3 straddle the top of the embossing table 1, the two sides of its front end are fixedly connected to the two sides of the front end of the embossing table 1 through the vertical rod 3-1, and the two sides of its rear end pass through the main wallboard 3-2 is fixedly connected to both sides of the rear end of the embossing...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap