A mechanical synchronizer

A synchronizer and mechanical technology, applied in the direction of the transmission device to drive multiple propellers, etc., can solve the problems of high use and maintenance cost, high technical level requirements, and many safety hazards, and achieve convenient use and maintenance, broad market prospects, Safe and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

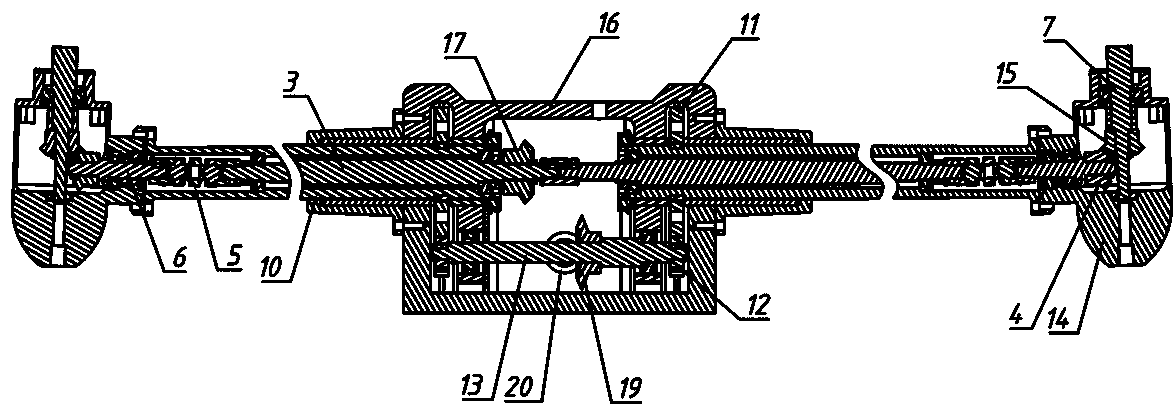

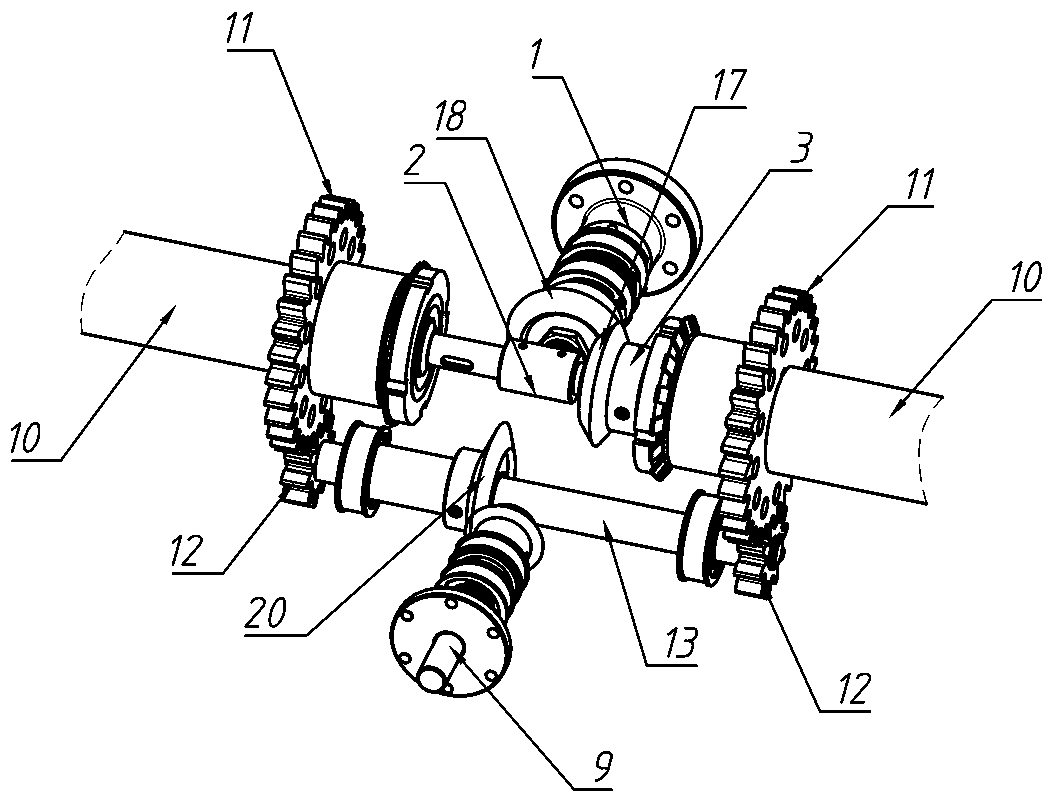

[0035] A mechanical synchronizer of the present invention comprises a synchronizer box 16, at least two transmission shafts 3 connected to the synchronizer box 16 at one end, and the other end of the transmission shaft 3 is connected to the propeller power input shaft 7;

[0036] The synchronizer case 16 includes at least one direction changing mechanism, which can synchronously change the power of the power input shaft of the synchronizer case 16 to the at least two transmission shafts 3;

[0037] The at least two transmission shafts 3 are hyperbolic reduced-diameter transmission shafts 3;

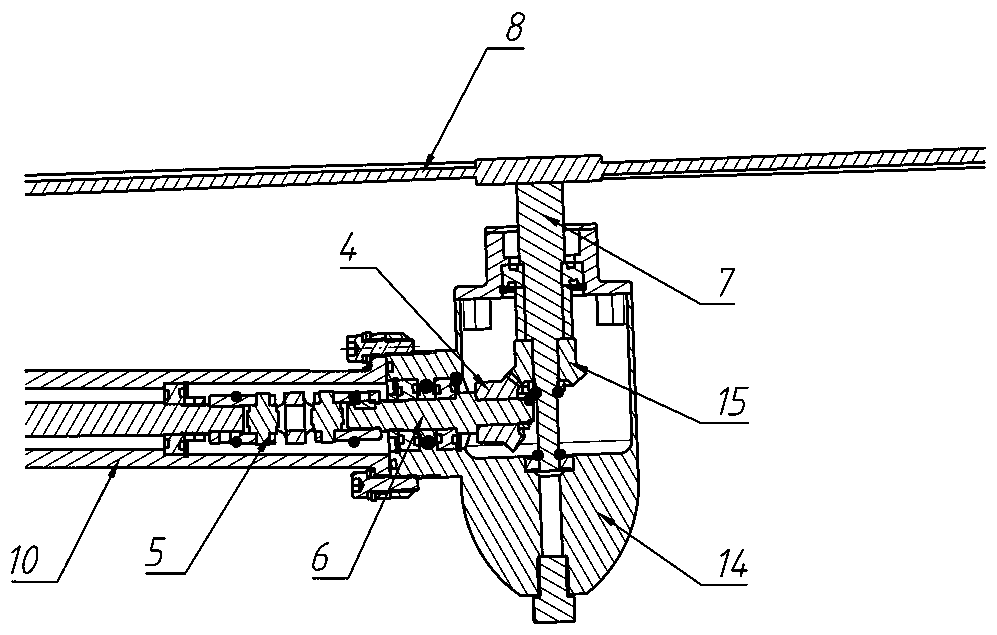

[0038] The end of the transmission shaft 3 connected to the propeller power input shaft 7 also includes at least a direction changing mechanism, which can change the power of at least two transmission shafts 3 to the propeller power input shaft 7;

[0039] The propeller power input shaft 7 is connected to a transmission mechanism housing 14 through a support bearing sleeved on the propell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com