Conveying belt adjustment device used for carton sealing machine

A technology of adjusting device and conveyor belt, applied in packaging and other directions, can solve the problems of inconsistent production lines before and after the conveyor belt, increase the time for changing the carton line, affect the production efficiency of the assembly line, etc., to achieve fast and efficient line change, stable and reliable transmission, and convenient adjustment. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

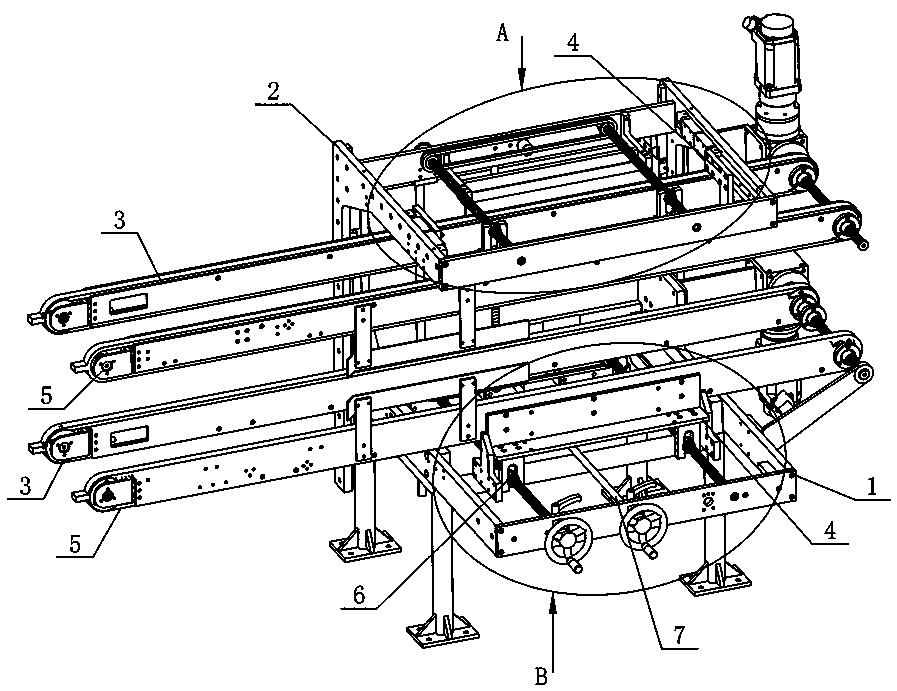

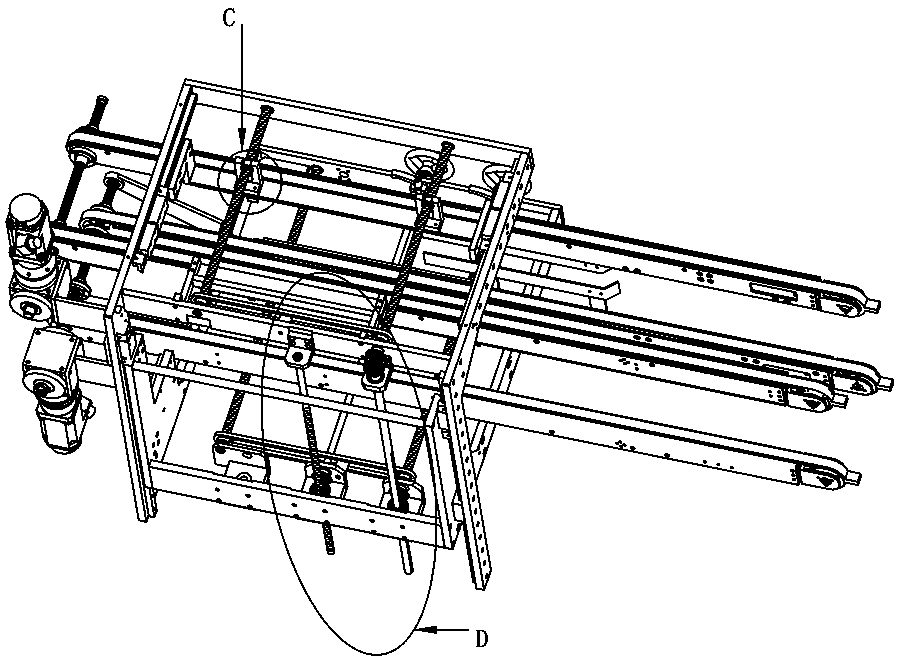

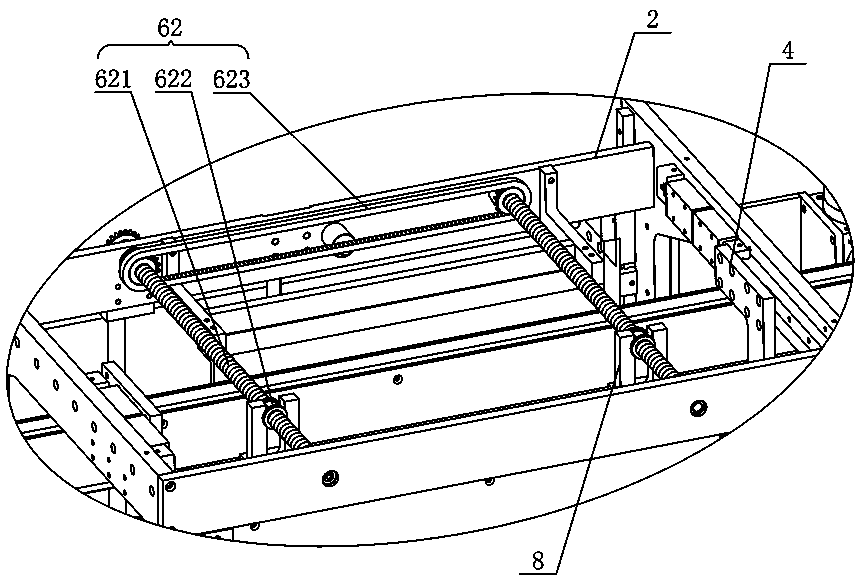

[0031] Figure 1 to Figure 6 It shows the conveyor belt adjustment device for the sealing machine of this embodiment, including a fixed bracket 1 and a height adjustment bracket 2, the height adjustment bracket 2 is slid on the fixed bracket 1, and both the fixed bracket 1 and the height adjustment bracket 2 are fixed The first conveyor belt 3 is arranged, and the fixed bracket 1 and the height adjustment bracket 2 are all slidably provided with a horizontally movable width adjustment bracket 4, and each width adjustment bracket 4 is fixedly equipped with a second conveyor belt 5, between each conveyor belt A box conveying channel is formed. The fixed support 1 is equipped with a width adjustment mechanism 6 for driving the two width adjustment supports 4 to move horizontally synchronously. The fixed support 1 is equipped with a heigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com