Automatic slitting device for chemical fiber paper tube and operation method thereof

A chemical fiber paper tube and slitting device technology, which is applied in the direction of transportation and packaging, sending objects, thin material processing, etc., can solve the problems of paper tube strength influence, burr removal efficiency is not high enough, lap seam arrangement is not uniform, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

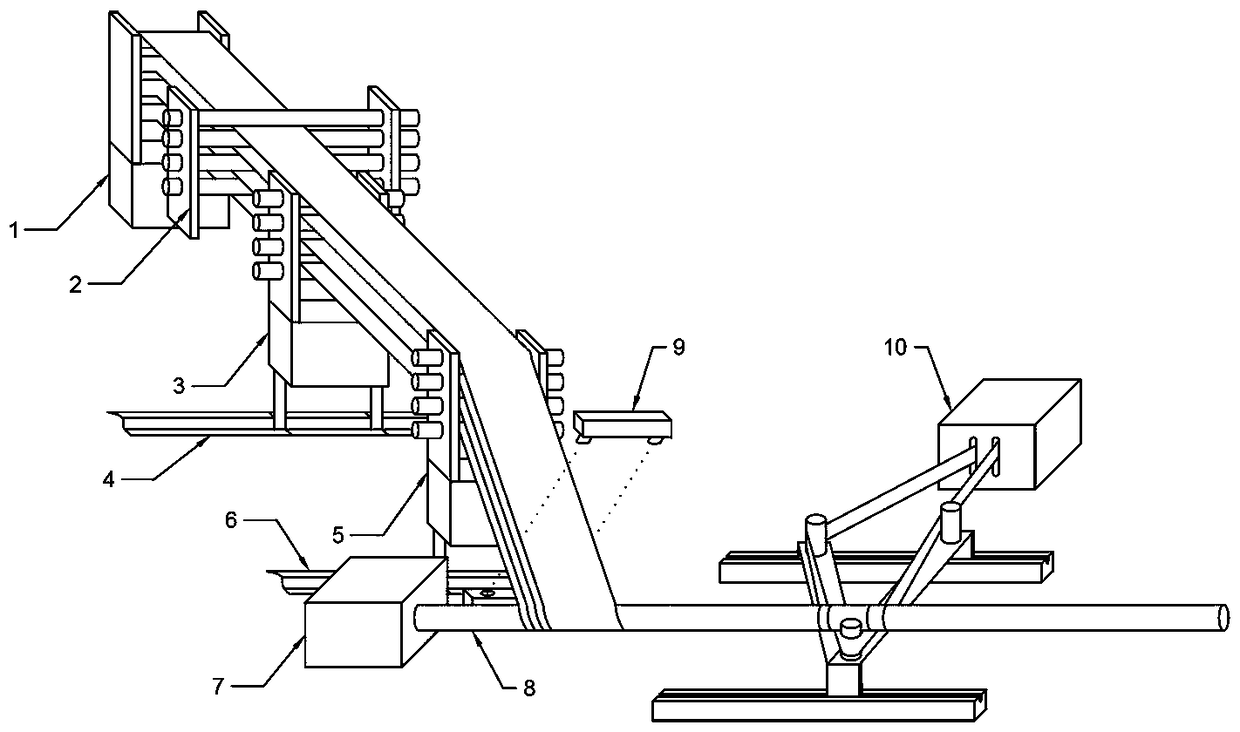

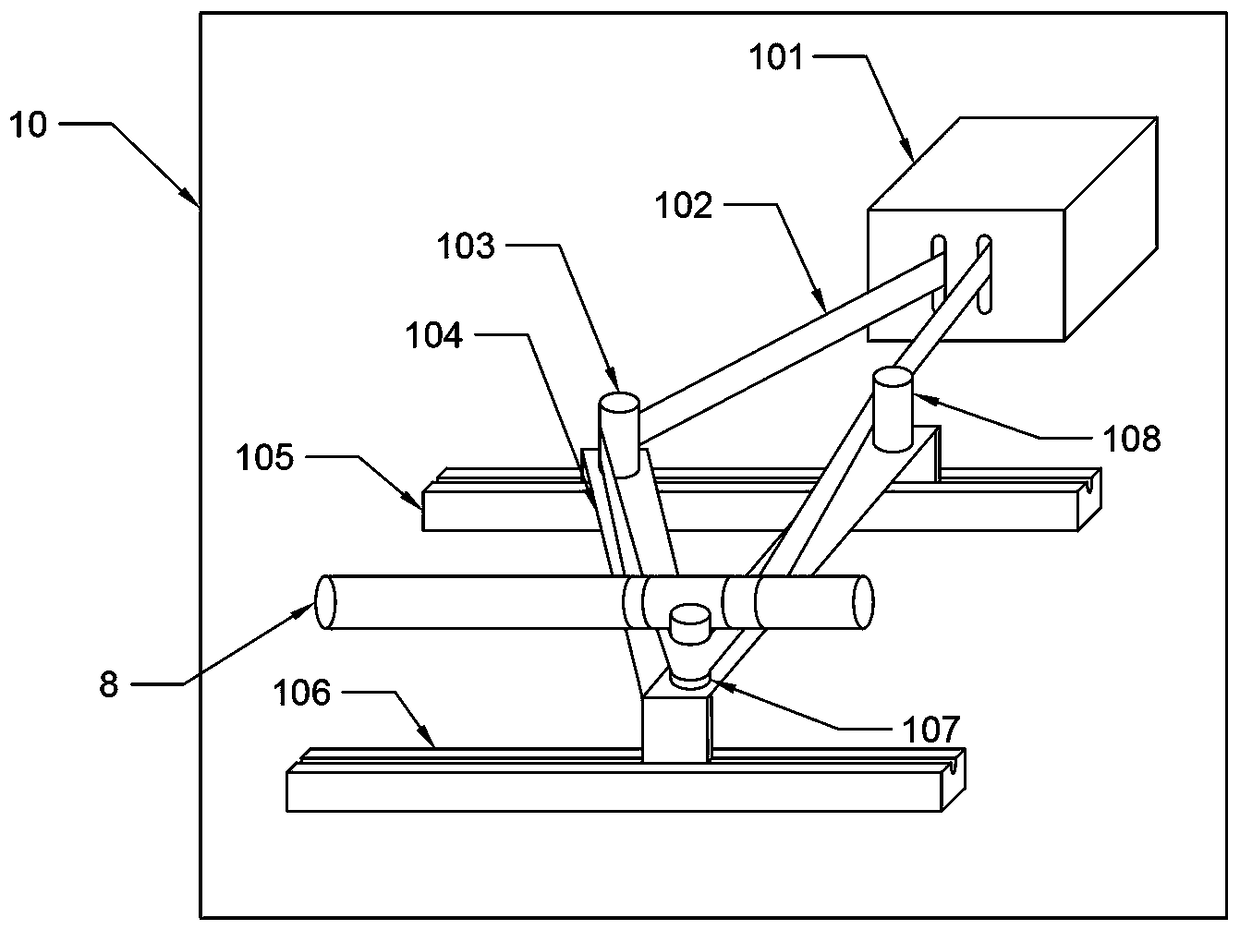

[0022] Embodiment, a kind of chemical fiber paper tube automatic slitting device and its operation method, see figure 1 As shown, it includes paper storage rack 1, No. 1 transmission rack 3, No. 2 transmission rack 5, motor 7 and paper reel 8, and also includes compression tube 2, No. Assembly 9 and hair removal assembly 10; motor 7 is fixedly connected to the front end of paper reel 8, hair removal assembly 10 is fixedly connected to the rear end of reel 8, and infrared monitoring assembly 9 is arranged on the left side of reel 8, two No. transmission frame 5 is arranged on the left side of infrared monitoring assembly 9, No. two transmission frame 5 is slidably connected to the upper end of No. two slide rail 6, No. one transmission frame 3 is arranged on the left side of No. two transmission frame 5, No. one transmission frame 3 is slidably connected to the upper end of the No. 1 slide rail 4, the pressing tube 2 is arranged on the left side of the No. 1 transmission frame ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap