A kind of inorganic non-lead cesium bismuth halide cs 3 bi 2 x 9 Perovskite microdisk and its synthesis method

A synthetic method and inorganic non-technique, applied in the direction of bismuth compounds, inorganic chemistry, chemical instruments and methods, etc., can solve the problems of narrow synthesis window and difficulty in the synthesis of micron discs, and achieve the effects of low cost, regular shape and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

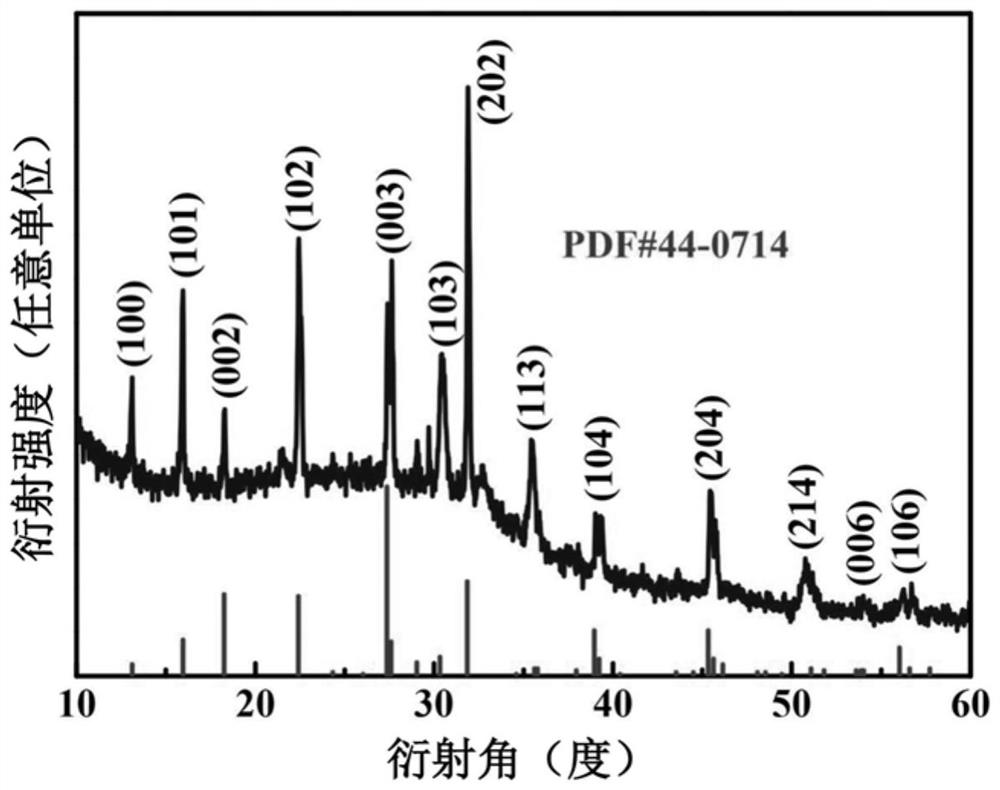

[0033] In the present invention, a kind of inorganic non-lead cesium bismuth halide Cs 3 Bi 2 x 9 A method for synthesizing perovskite microdisks, comprising the following steps:

[0034] (1) cleaning the substrate;

[0035] (2) Preparation of CsX and BiX 3 The mixed powder of X=Cl, Br or I;

[0036] (3) Put the cleaned substrate and the prepared mixed powder into a double temperature zone horizontal tube furnace;

[0037] (4) Set the appropriate temperature, holding time and pressure of the horizontal tube furnace;

[0038] (5) Introduce high-purity argon as a carrier gas to produce high-quality, regular-shaped Cs 3 Bi 2 x 9 Perovskite microdisks.

[0039] In step (1), the substrate was ultrasonically cleaned in acetone, ethanol and deionized water for 10 minutes, and then dried with high-purity nitrogen.

[0040] In step (2), prepare CsX, BiX according to the molar ratio of 3:2 3 mixed powder.

[0041] In step (3), the cleaned substrate is placed on the ceramic b...

Embodiment 1

[0050] (1) The substrate is cleaned, and the substrate is SiO 2 / Si substrate;

[0051] Using SiO 2 / Si is the substrate, SiO 2 The thickness of the layer is 300nm, and it is chemically cleaned. The cleaning steps are: put the substrate in acetone, ethanol and deionized water and ultrasonically clean it for 10 minutes; then dry it with high-purity nitrogen and set it aside.

[0052] (2) Preparation of CsBr and BiBr 3 mixed powder;

[0053] Weigh 0.1277 g of CsBr powder and BiBr powder with a high-precision electronic balance 3 Powder 0.1795 g, then mix the two powders evenly. To prevent CsBr and BiBr 3 The powder absorbs moisture, and the weighing process is completed in a nitrogen-protected glove box.

[0054] (3) Put the cleaned substrate and the prepared mixed powder into a double temperature zone horizontal tube furnace;

[0055] Cleaned SiO 2 / Si substrate placed in the low temperature zone of the horizontal tube furnace, SiO 2 Face up; place the prepared mixed ...

Embodiment 2

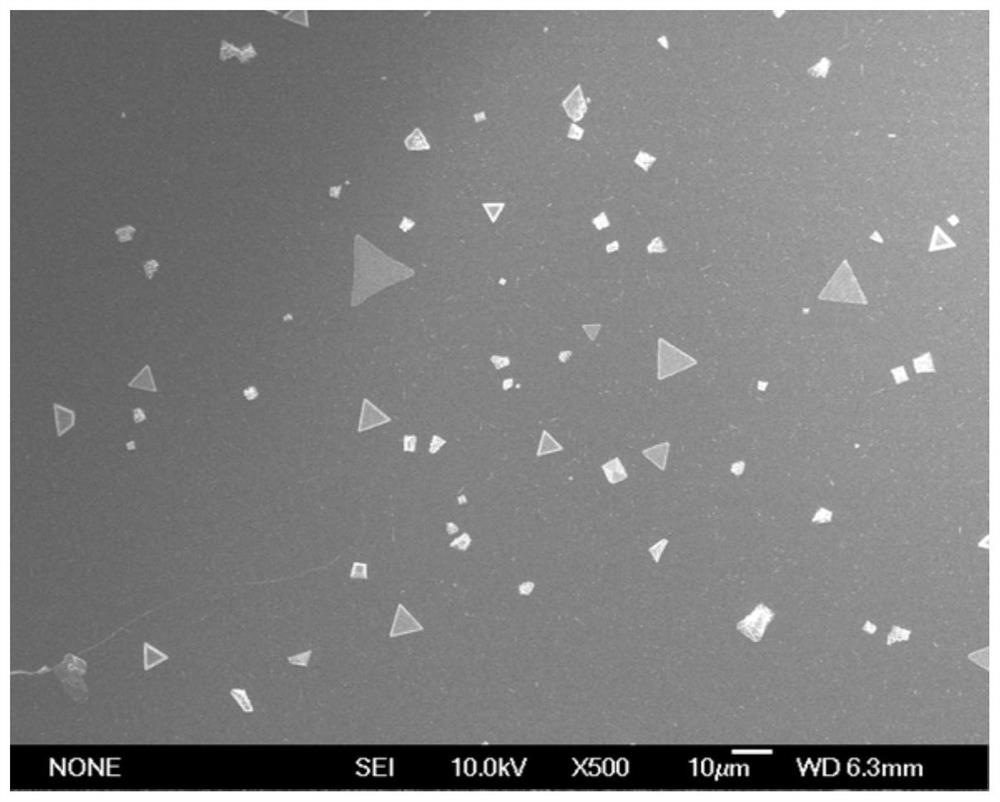

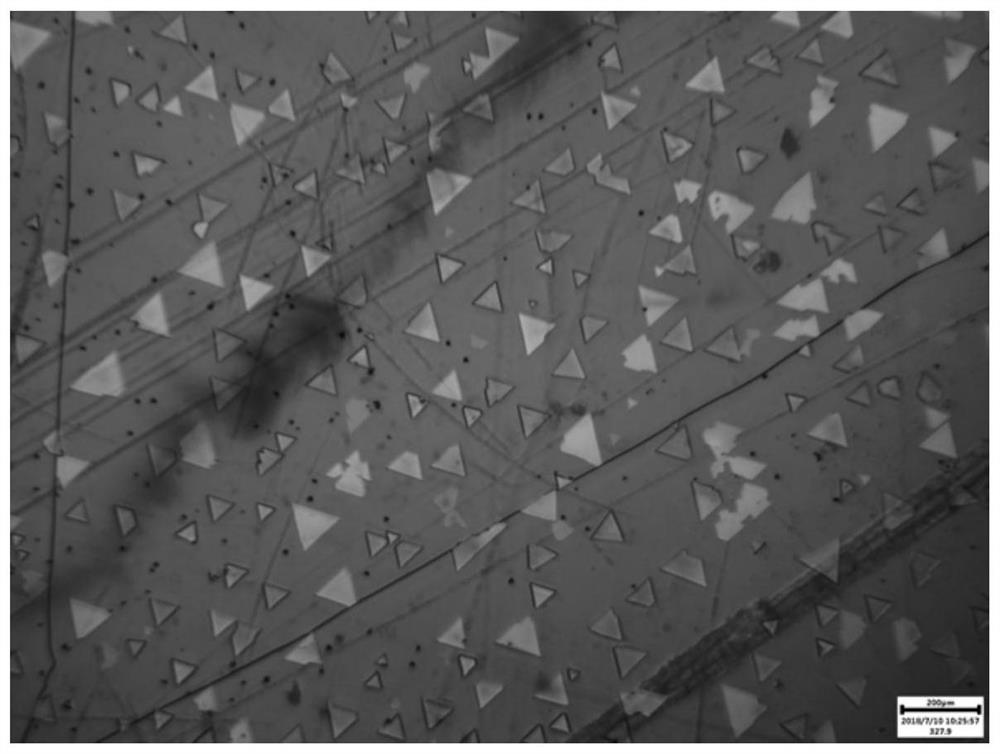

[0062] This example is basically the same as Example 1, except that the substrate in step (1) is mica, and other growth parameters remain unchanged. Due to the good insulation and layered structure of mica, it is more conducive to obtaining regular Cs 3 Bi 2 Br 9 Perovskite microdisks. image 3 For adopting the Cs prepared in Example 2 3 Bi 2 Br 9 The optical microscope photo of the perovskite microdisk, the microdisk is composed of a large number of regular triangles, the size of the triangles is distributed in the range of 15-100 microns, and the average size is obviously larger than the sample obtained in Example 1. Figure 4 For adopting the Cs prepared in Example 2 3 Bi 2 Br 9The scanning electron microscope photo of the perovskite microdisk, from which it can be observed that the surface of a single microdisk is very smooth and flat, the boundary is very steep, and there are no obvious defects.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com