Water treatment rapid assembly equipment based on assembleable modules

A technology for assembling equipment and water treatment devices, which is applied in water/sewage treatment equipment, water/sewage treatment, water treatment parameter control, etc., can solve problems such as single equipment, high use cost, and complex structure, so as to save operating costs, The effect of saving construction costs and having a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment a

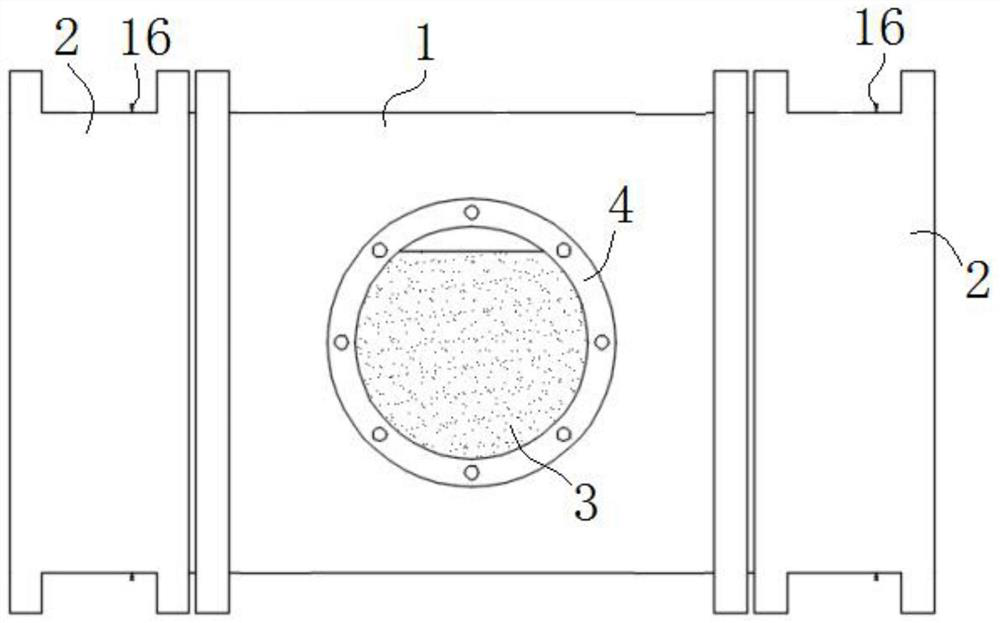

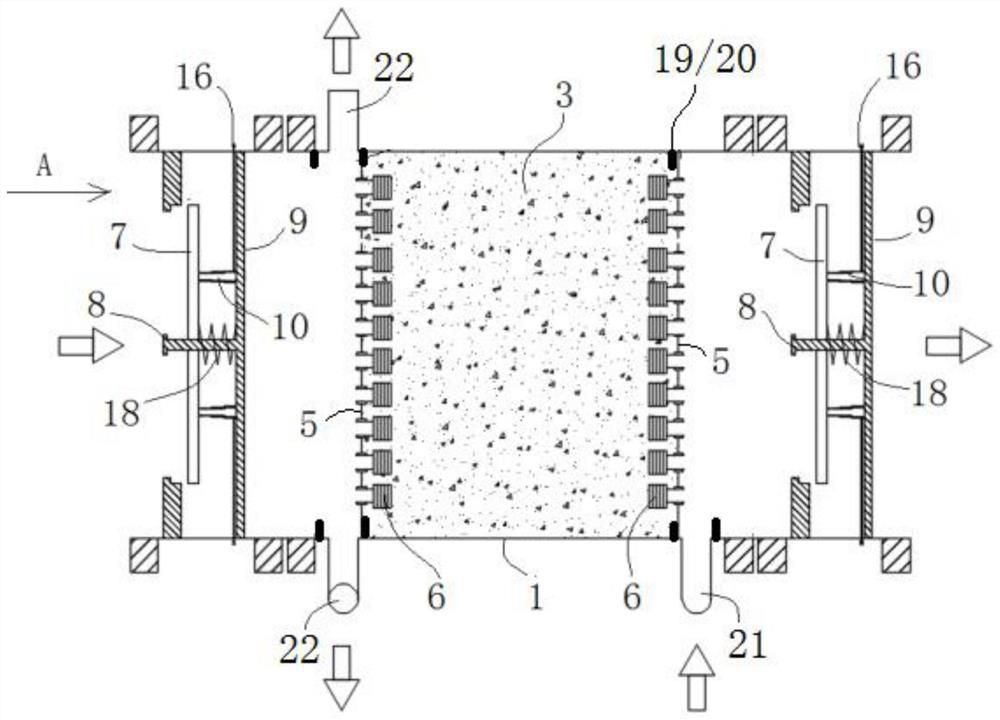

[0045] Embodiment a, as Figure 2-3 shown, solid filter substances such as activated carbon particles or high-fiber tissues

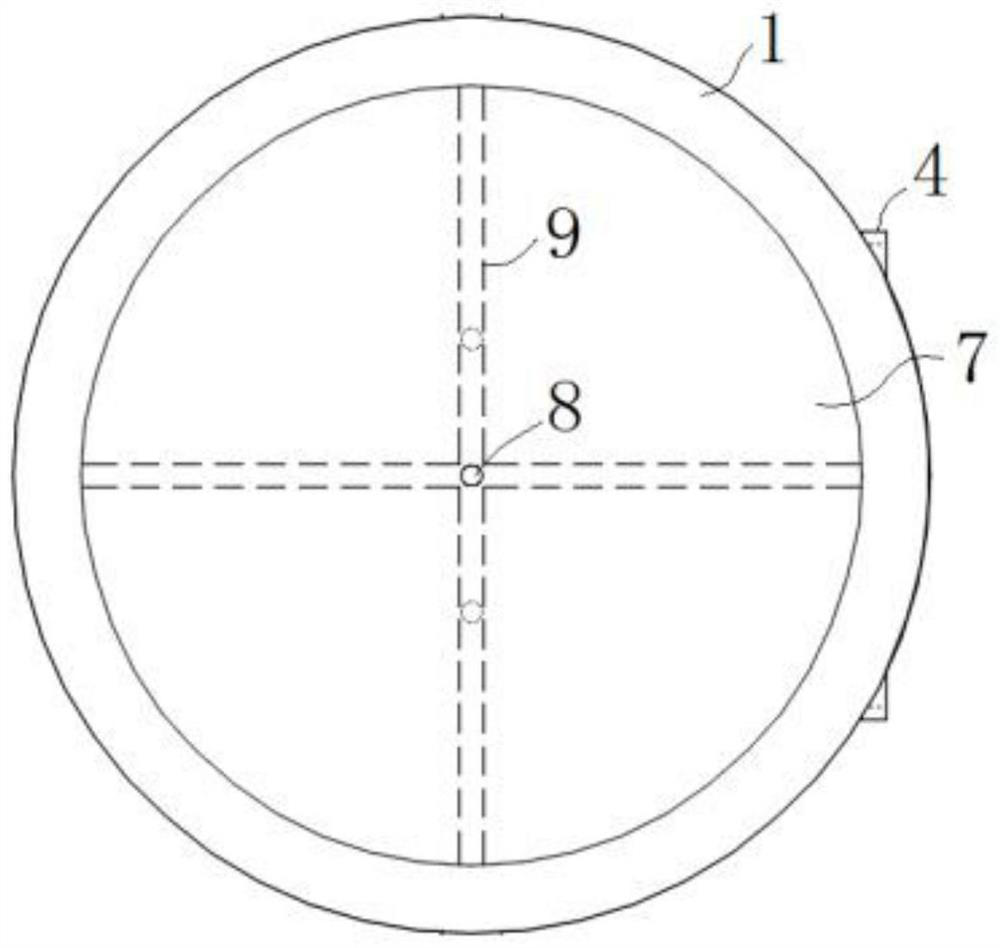

[0046] In this device, the water treatment device 5 is preferably a round cake-shaped filter space composed of two filter partitions 21. The shape of the filter partition 21 is the same as the cross-sectional shape of the tubular body 1, and the filter partition 21 is detachably installed on the tubular body. 1, fillers and elements 3 fill the round cake-shaped filter space, and the filter separator 21 is covered with liquid holes, so that the filter area is the largest and the filter effect is the best.

[0047] Due to the small weight and strong adsorption of solid filter materials such as activated carbon particles or high-fiber tissue, there is no special direction requirement for backwash water, and the backwash effect is good. The backwash outlet 23 is located outside the filter partition 21 in the liquid inlet chamber. , wherein the backwash out...

Embodiment c

[0052] Embodiment c, such as Figure 6 As shown, when the water treatment filler 3 is filled with bulk cation exchange resin or anion exchange resin, in order to prevent resin expansion, a certain space should be reserved according to the expansion rate of the corresponding resin during filling.

[0053] In this device, it is preferable to set the water treatment device 5 along the central axis of the tubular body 1. The filtration area can be increased by extending the water treatment device 5. The partition structure is connected from the liquid inlet end of the water treatment device 5, and after passing through the water treatment device 5 horizontally Connected from the liquid outlet of the water treatment device 5, the upper and lower parts of the water treatment device 5 are divided into a liquid outlet chamber and a liquid inlet chamber.

[0054] Since the packing and element 3 run from bottom to top, backwashing and regeneration can only take in water from the upper p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com