Inserting central shaft, frame strip of window frame and window frame and fixed frame assembly

A technology for fixing frame and window frame, applied in the field of window structure, can solve the problems of complex assembly, difficult operation, affecting the appearance, etc., and achieve the effect of high assembly flexibility and high variability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

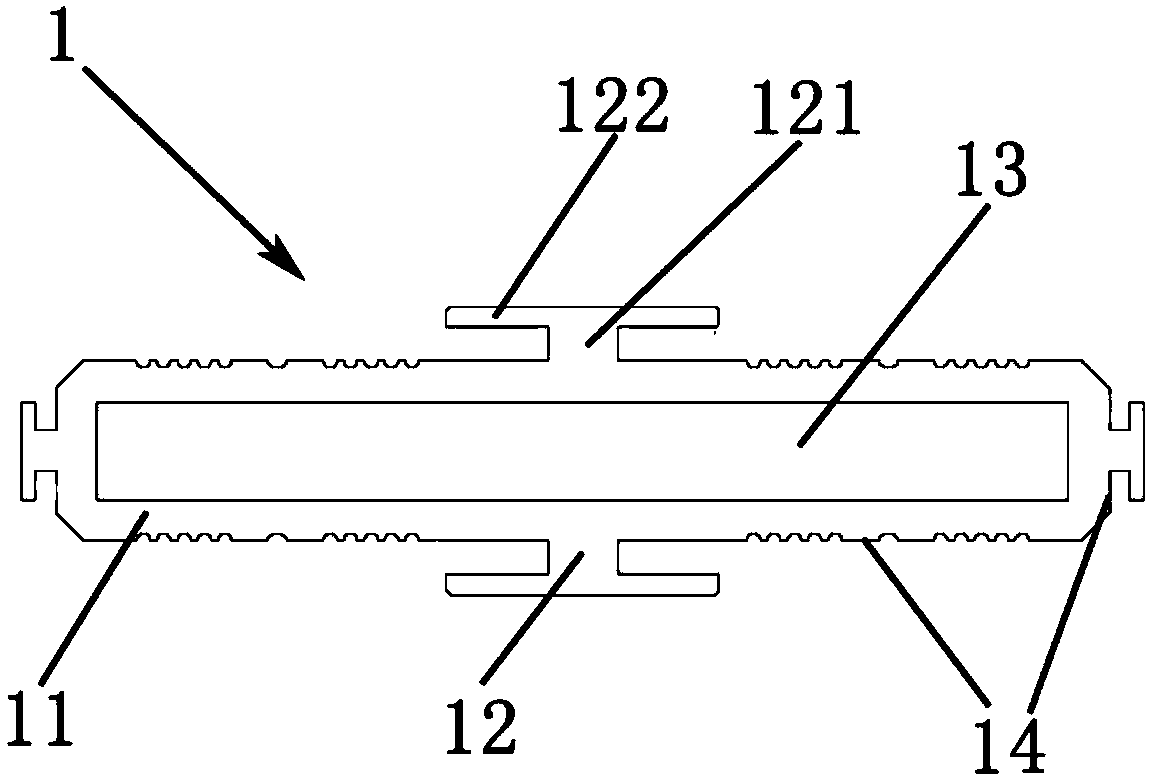

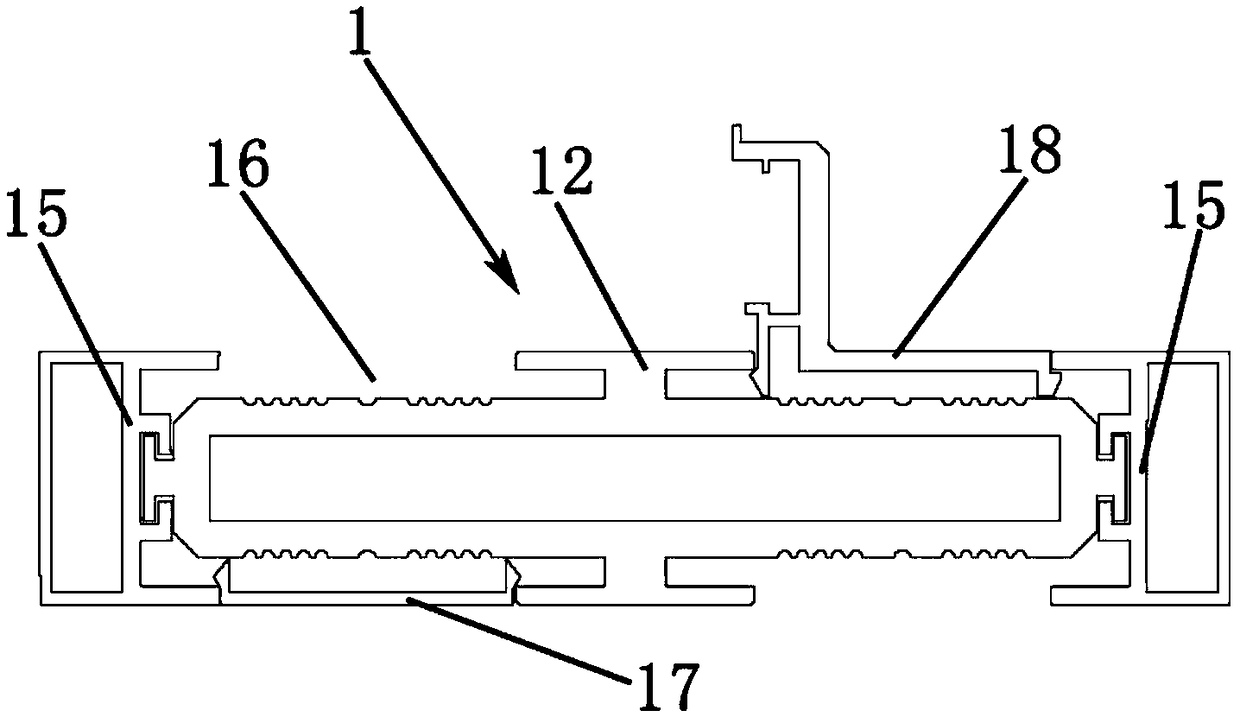

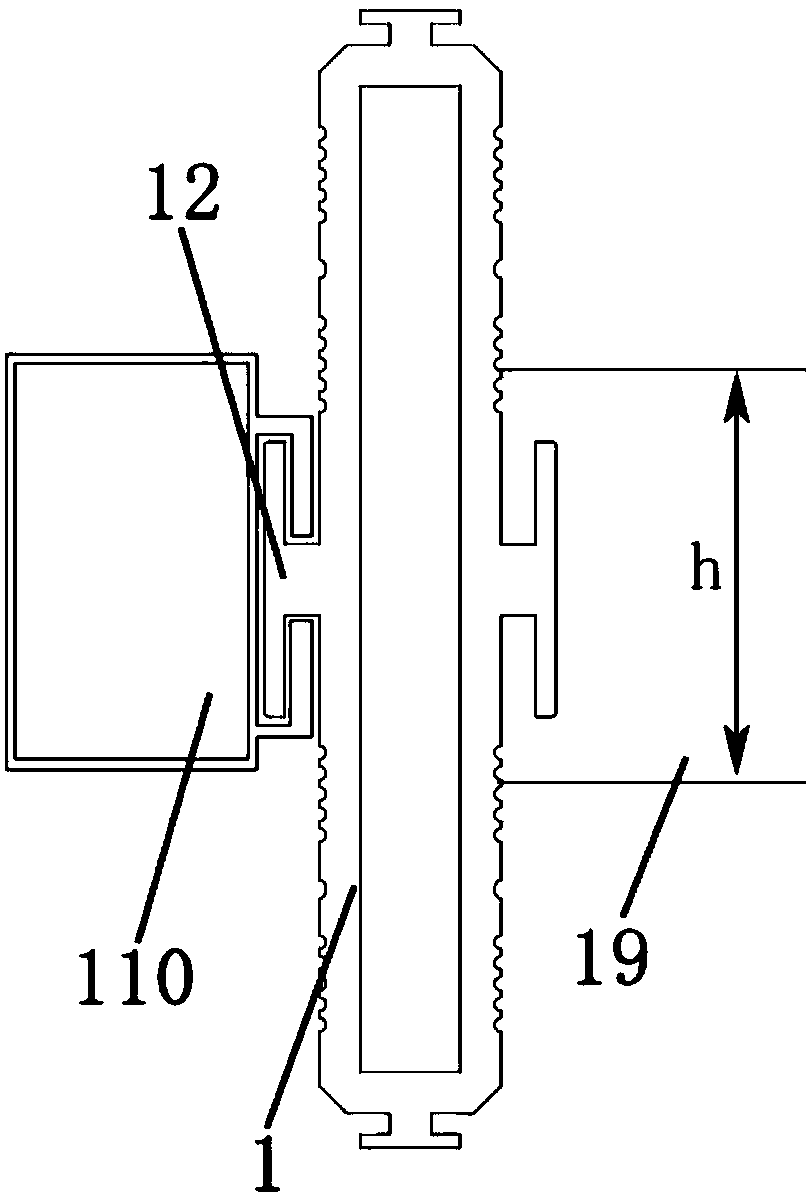

[0038] The plug-in central axis provided by the present invention is longitudinally long, and the components forming the window frame are inserted and connected to the vertically long plug-in central shaft to form frame strips. while in Figure 1 to Figure 6 In , the given views are all viewed from the axial direction of the plug-in axis, therefore, all the figures shown in the drawings are the cross-sectional shapes of the components. exist Figure 3 to Figure 6 The h given in refers to the thickness direction of the glass. exist Figure 3 to Figure 5 In , the glass installation cover is omitted, the structure of the glass installation cover and the matching relationship between the glass installation cover and the glass can be referred to Figure 6 .

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com