Laser calibrator for pumping unit suspension point and operation derrick pulley center and wellhead alignment

A technology for operating derricks and pumping units, which is applied to wellbore/well components, drilling equipment, drilling pipes, etc. It can solve the problems of wasting electric energy, oil leakage from tubing, and reworkover, etc., and achieves no deviation and high alignment accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

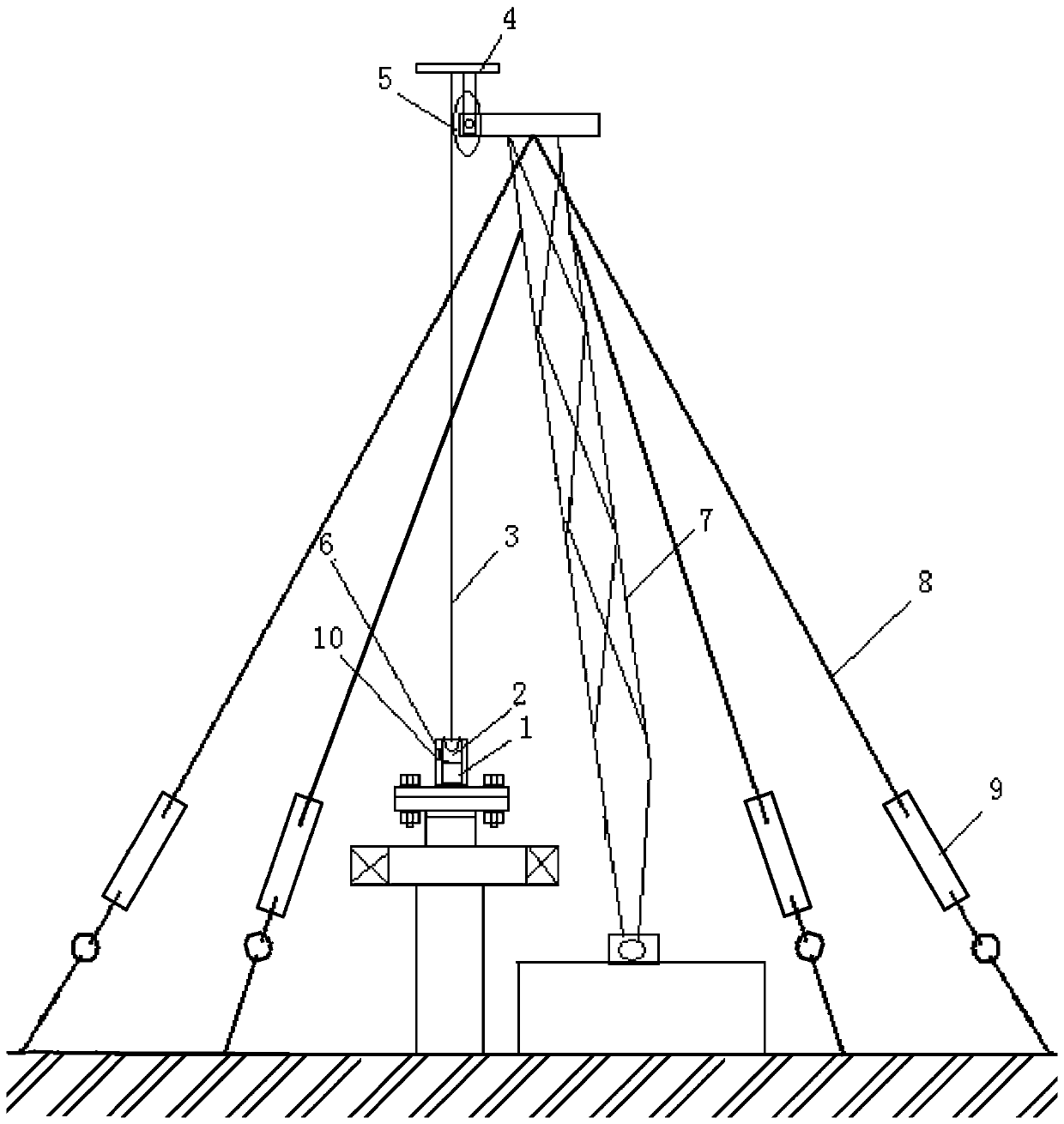

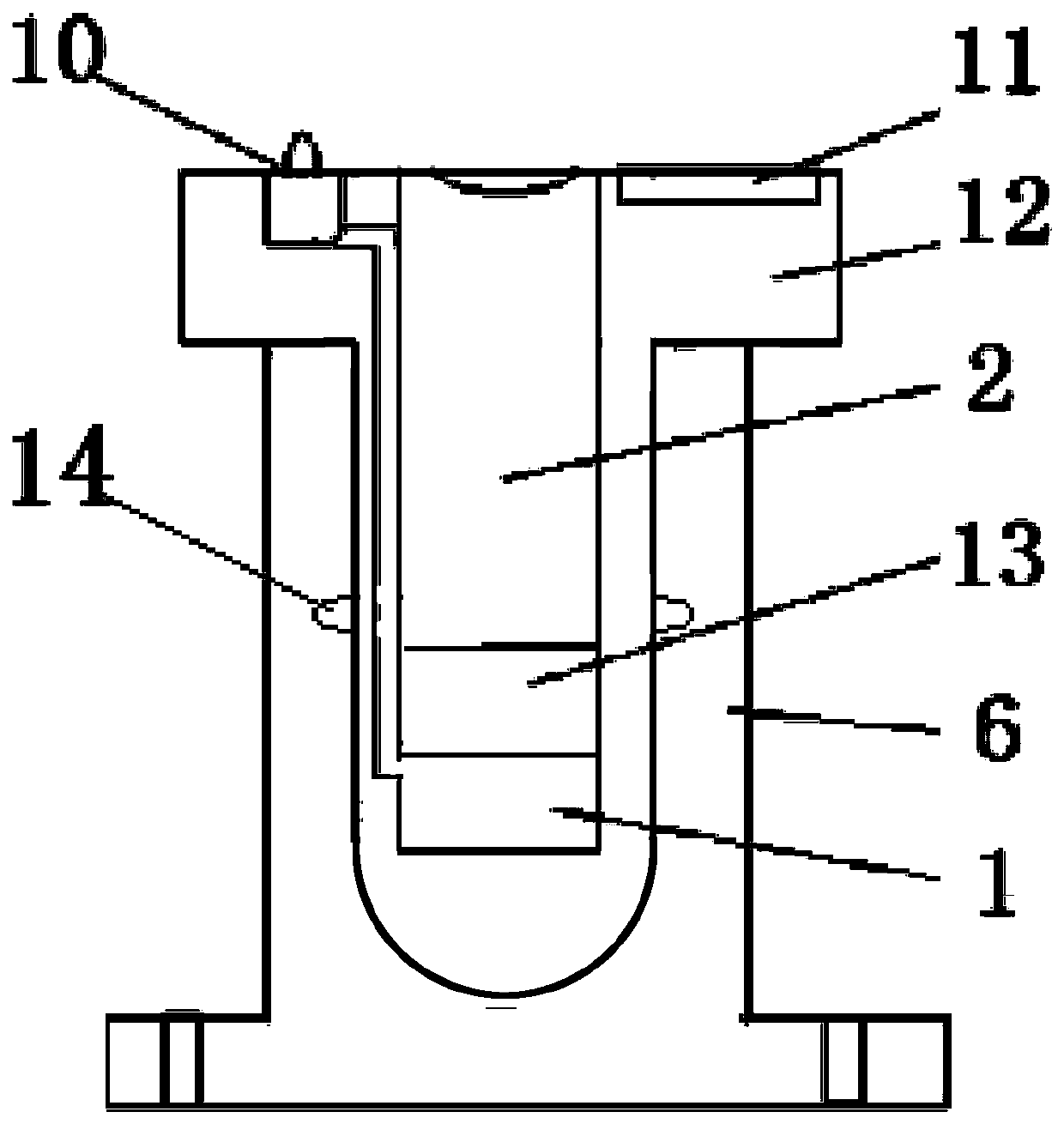

[0017] In order to further disclose the technical solution of the present invention, the following will be described in detail through the embodiments in conjunction with the accompanying drawings:

[0018] Laser calibrator for suspension point of pumping unit and operation derrick pulley center and wellhead alignment, including: laser 2, laser circuit 13, laser power supply 1, laser installation sleeve 6, universal head 12, laser power switch 10, spirit level 11, The laser calibration board 4 and the casing four-way; it is characterized in that: the laser installation sleeve 6 is set in a cylindrical shape, and the lower end is provided with a flange matched with the casing four-way flange, and the lower part of the laser installation sleeve is provided with The universal head seat, the universal head 12 is arranged on the universal head seat, the laser power supply 1 is arranged on the lower part of the universal head 12, the laser circuit 13 is arranged on the upper part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com