Liquid-controlled type under-shaft savaging tool

A salvage tool and hydraulic control technology, applied in wellbore/well parts, earthwork drilling and other directions, can solve the problems of falling fish, poor control of the rotation angle, and failure of salvage, etc., and achieve the effect of preventing falling fish from falling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

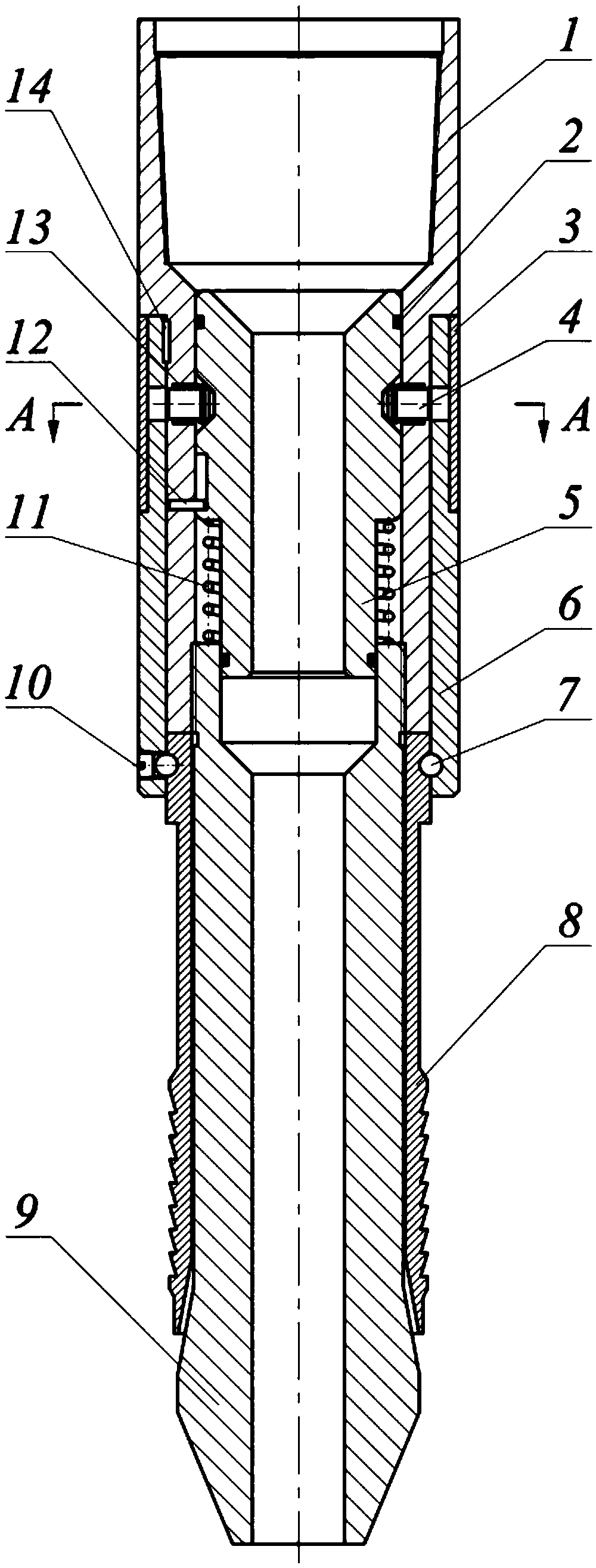

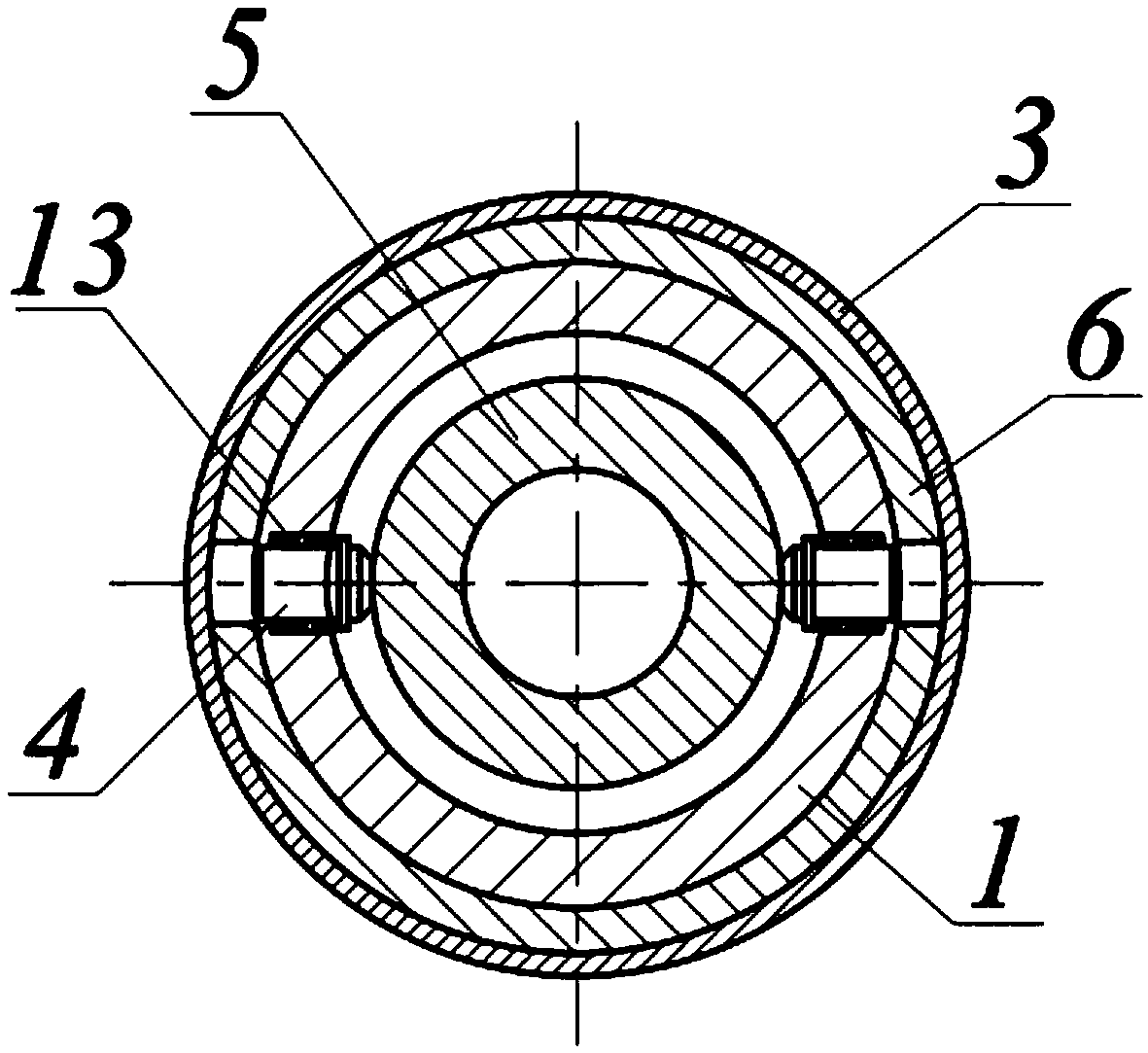

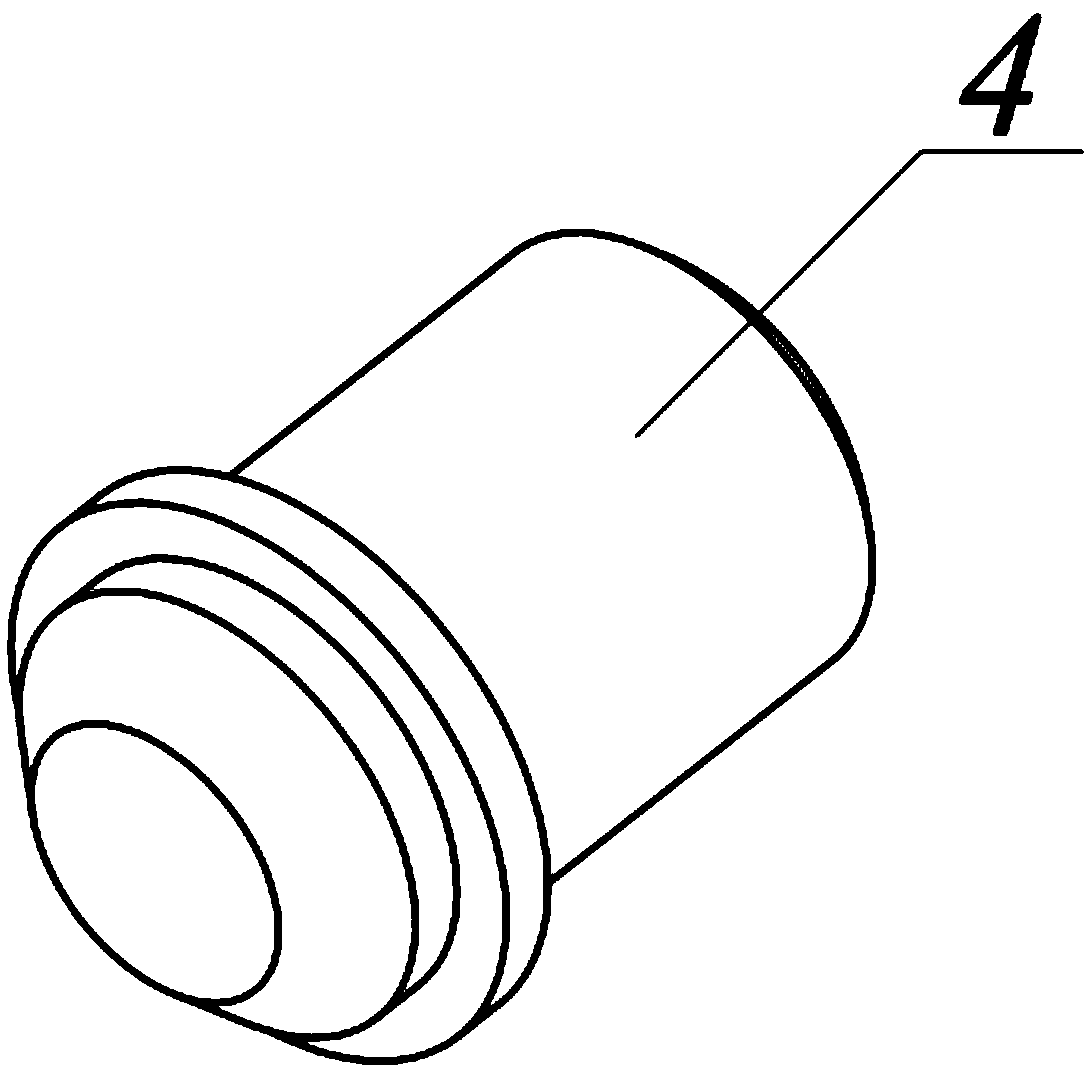

[0018] Such as Figure 1-Figure 7 As shown, a hydraulically controlled downhole fishing tool is mainly composed of a joint 1, a sealing ring 2, a sliding sleeve 3, a fixed pin 4, a piston 5, a casing 6, a steel ball 7, slips 8, a mandrel 9, a screw 10, a reset Spring 11, travel pin 12, pin spring 13, semicircular key 14 are characterized in that: described joint 1 and mandrel 9 are connected by screw thread, and joint 1 is provided with the pin hole that installs fixed pin 4 and pin spring 13; The piston 5 is installed in the joint 1, and its upper end is provided with an annular groove 5a that matches the fixed pin 4, and both sides of the annular groove are provided with inclined surfaces, and the middle part of the piston 5 is provided with a stroke groove 5b, which is used to control the stroke of the piston 5 The fixed pin 4 is installed in the pin hole of the joint 1, and its other end is inserted into the ring groove 5a of the piston 5; the shell 6 is set on the joint 1...

Embodiment example 2

[0020] During the fishing operation, the fishing tool is connected to the lowermost part of the downhole string, the threads are tightened, and the tool is lowered into the well. When the lowering device is 1-2m away from the top of the fish, stop lowering and record the total weight suspended at this time. Then turn on the mud pump to rinse the fish. After washing the fish, turn off the mud pump and continue to lower the fishing tool slowly. When the suspended weight returns to lower, stop lowering and try to lift the drill string. After confirming that the fish is caught, lift the device and take out the fish. If the fish gets stuck in fishing, lower the tool string, stop the lowering when the index weight gauge is lowered below the suspended weight, turn on the mud pump for about 10 seconds, and then lift the string to pull the tool out of the fish.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com