Ball-type valve assembly structure

An assembly structure and ball-type technology, which is applied to variable displacement pump components, components of pumping devices for elastic fluids, machines/engines, etc., can solve the problem of laborious disassembly and assembly, narrow internal space of the liquid end, increased Cost and labor load of operators and other issues, to achieve the effect of avoiding sticking, convenient disassembly and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

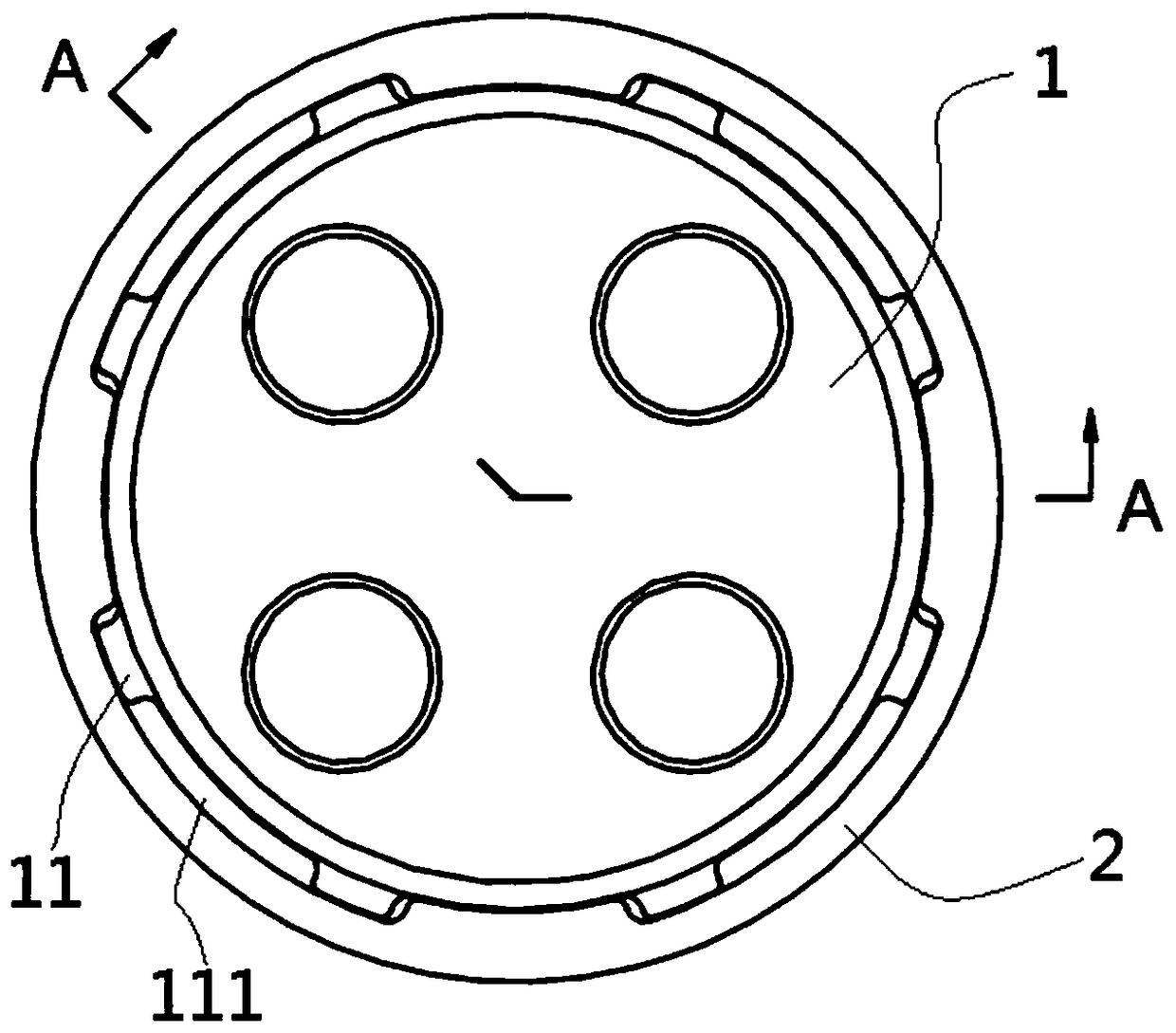

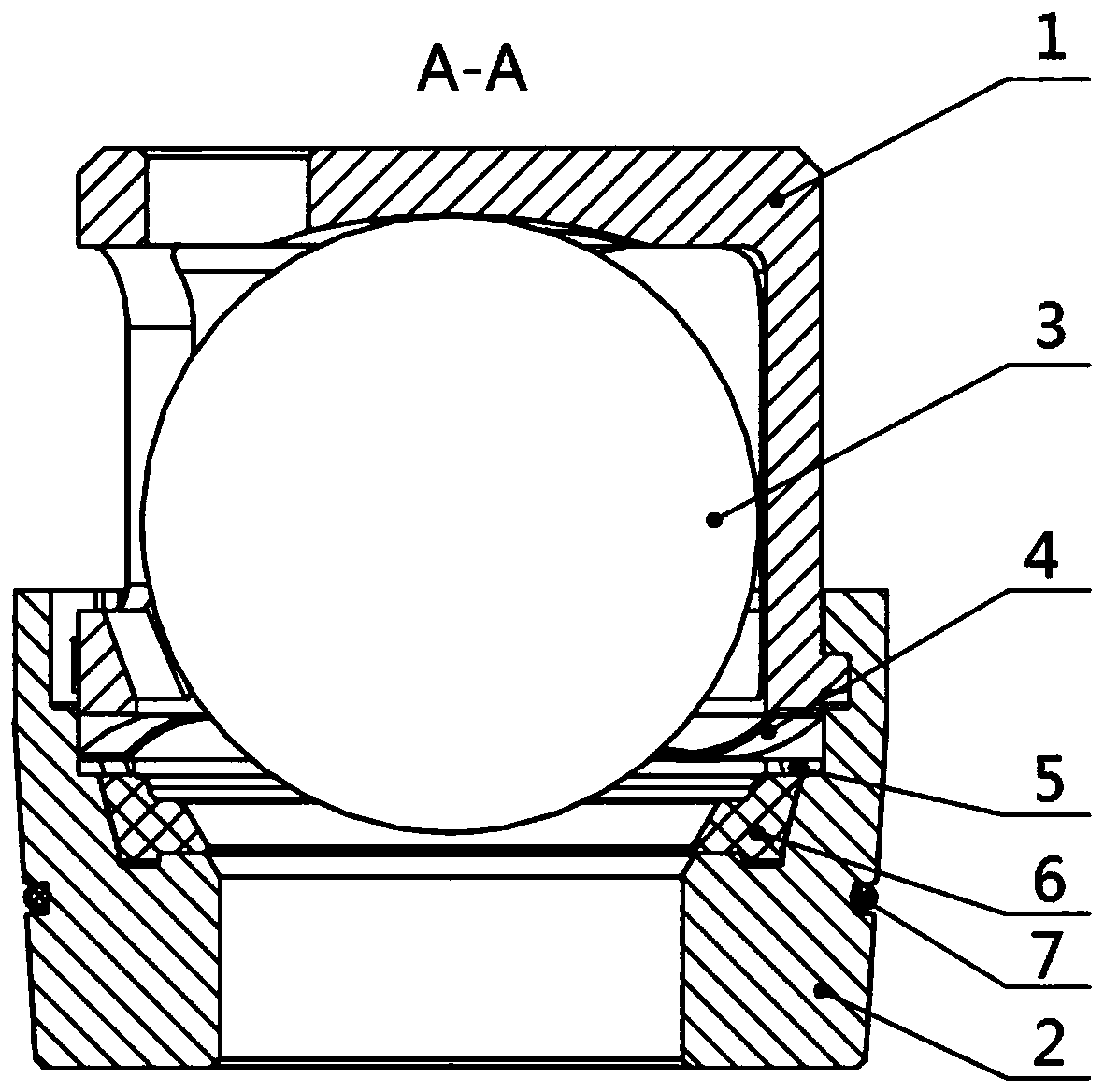

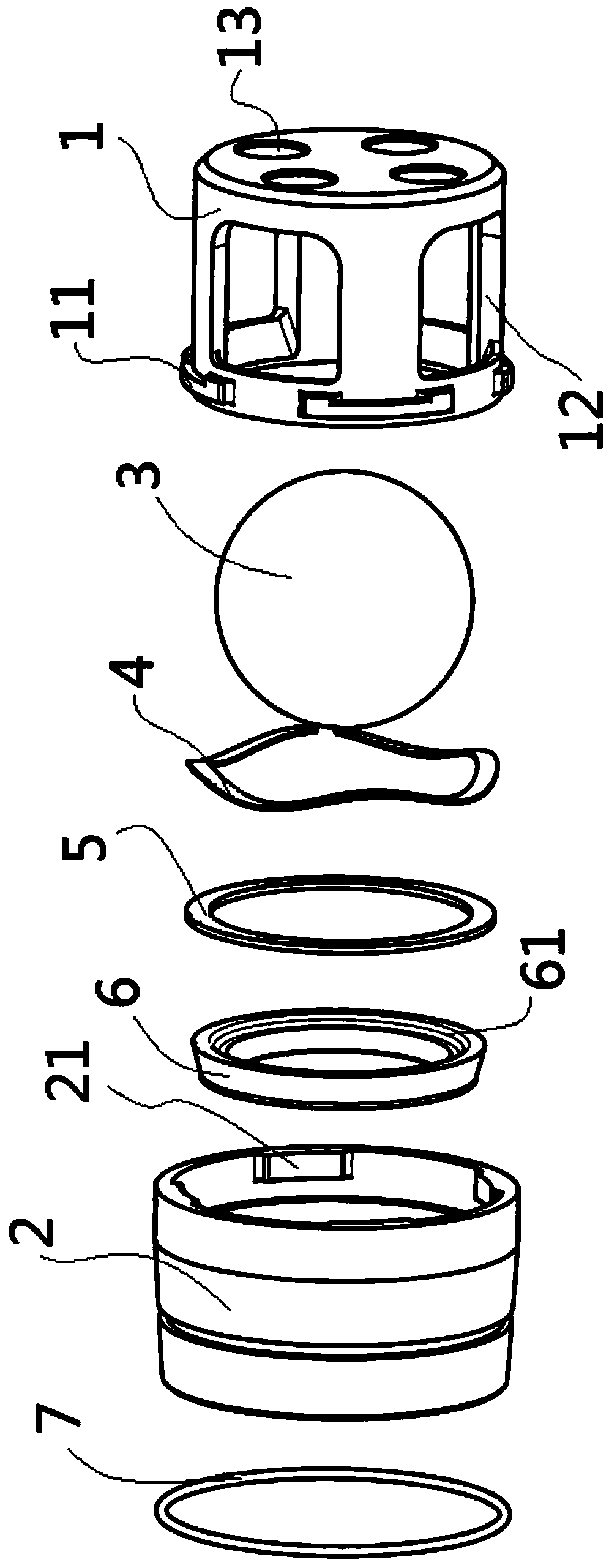

[0022] Such as Figure 1 to Figure 3 As shown, the ball type valve assembly structure of the present invention includes valve seat 2, valve rubber 6, steel ball 3 and ball cage 1, valve rubber 6 is installed on the inner side of valve seat 2, steel ball 3 is installed on The top of the Vall rubber 6 and the outside of the steel ball 3 are provided with a ball cage 1. During operation, when the fluid flows upward from the bottom of the valve seat 2, the steel ball 3 can be lifted up and moved upward, and then the steel ball 3 is separated from the valve rubber 6 and the valve seat 2 to form a gap for the fluid to pass through, and finally from the ball cage 1 The side fluid hole 12 flows out; when the fluid enters the side fluid hole 12 of the ball cage 1 and wants to flow downward, due to the self-weight of the fluid and the steel ball 3 itself...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com