Photovoltaic emulator, light intensity adjusting method, electronic equipment and storage medium

A photovoltaic simulator and photovoltaic cell technology, applied in the photovoltaic field, can solve problems such as uncontrollable output power of light source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Since the photovoltaic simulator in the prior art cannot control the output power of its own light source, in order to ensure that the light intensity of the light source reaches the standard test light intensity specified by the IEC, the prior art will use manual timing and manual adjustment to adjust the output power of the light source. However, the method of manual timing and manual adjustment not only consumes manpower, but also takes up more production time when the photovoltaic simulator is applied to the assembly line, resulting in lower production efficiency.

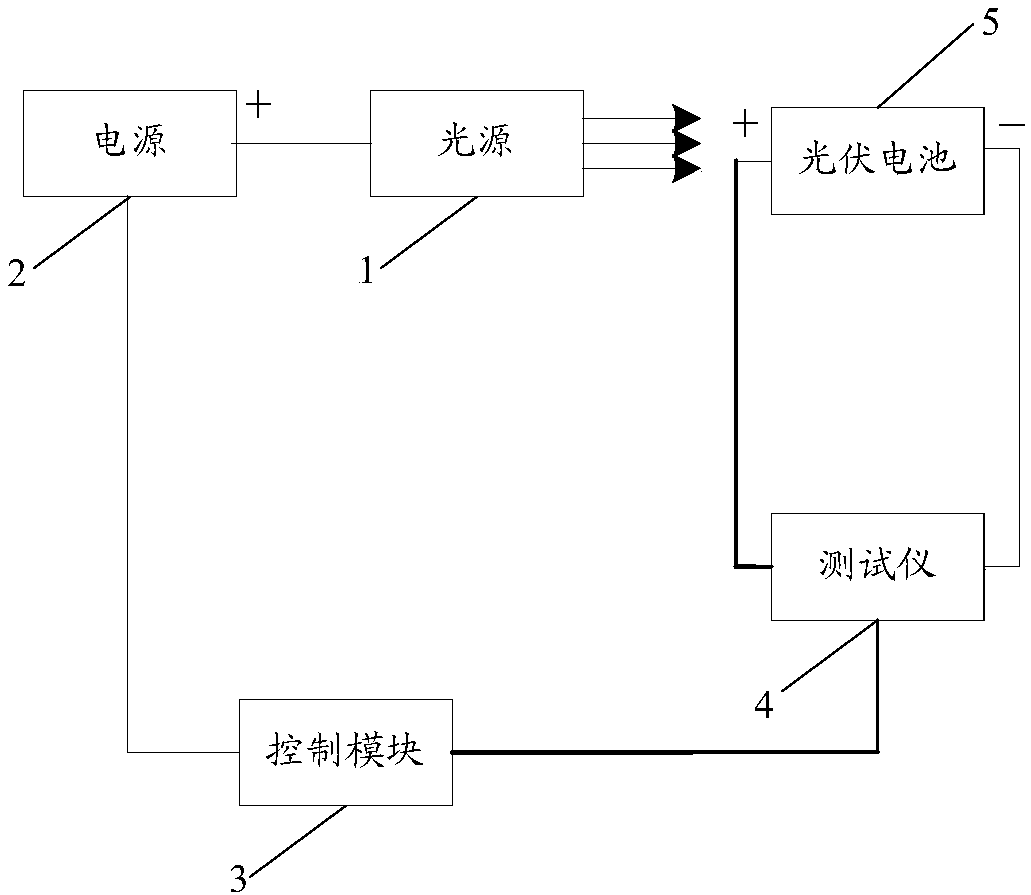

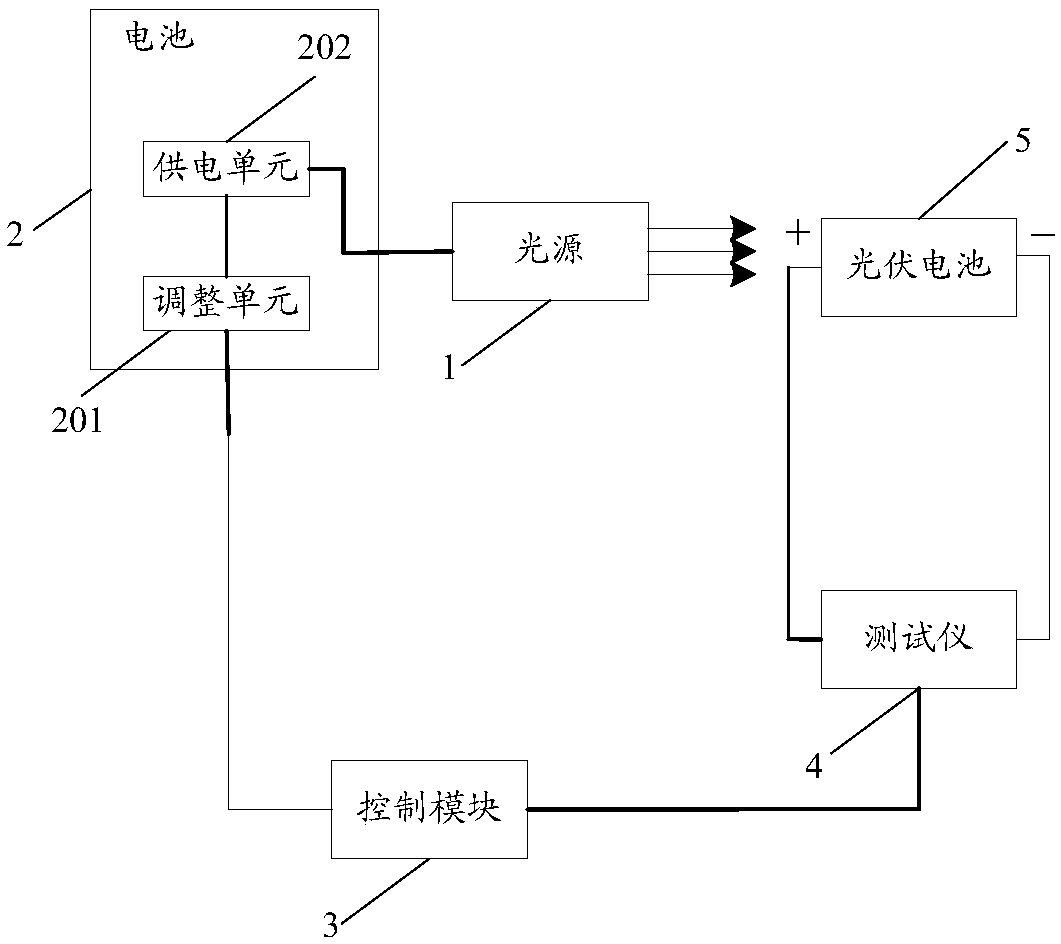

[0043] Therefore, in order to overcome the technical problem that the photovoltaic simulator in the prior art cannot control the output power of its own light source, the embodiment of the present invention provides a photovoltaic simulator, including a light source 1 for illuminating the photovoltaic cell 5, such as figure 1 As shown, the photovoltaic simulator also includes: a power supply 2 for the lig...

Embodiment 2

[0055] On the basis of the above-mentioned embodiments, in the embodiment of the present invention, the control module 3 is further configured to determine whether the error rate is greater than a preset value before determining the calibration value of the output power of the light source according to the error rate The allowable error rate of , if yes, proceed to the next step.

[0056] In the embodiment of the present invention, by comparing the error rate between the current value and the standard current value with the preset allowable error rate, it can be realized that while ensuring that the light intensity of the light source 1 reaches the standard test light intensity specified by the IEC, And there is no need to adjust the output power of the light source 1 frequently, so as to ensure that the light source 1 can output in a steady state.

[0057] Wherein, in the embodiment of the present invention, the allowable error rate between the current value and the standard ...

Embodiment 3

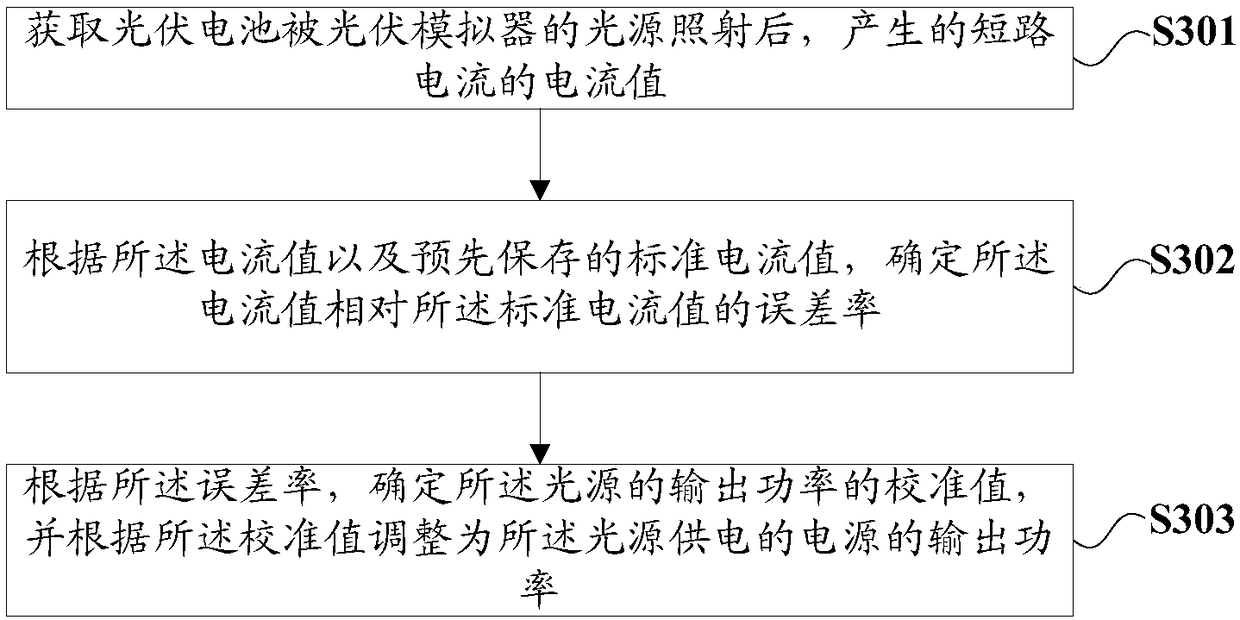

[0061] Since the short-circuit current generated by the photovoltaic cell 5 is proportional to the light intensity, and the light intensity of the light source 1 is related to its own output power, the short-circuit current is also proportional to the output power of the light source 1 . Therefore, when the current value obtained by the tester 4 does not reach the standard current value, the control module 3 can determine the calibration value of the output power of the light source 1 according to the error rate between the current value and the standard current value.

[0062] Therefore, on the basis of the above embodiments, in the embodiment of the invention, the control module 3 is specifically configured to determine the product of the error rate and the pre-stored standard output power as the output power of the light source 1 calibration value.

[0063] That is, if the current value sent by the tester 4 is 9.8A, and the standard current value is 10A, then the error rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com