A multi-point independent displacement detection device for steel strand clips used in the reverse pull method

A displacement detection and steel strand technology, applied in measuring devices, using stable tension/pressure to test material strength, instruments, etc., can solve problems such as on-site accidents, unrestricted clips, steel strand damage, etc. The effect of preventing turbulence, increasing usability, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

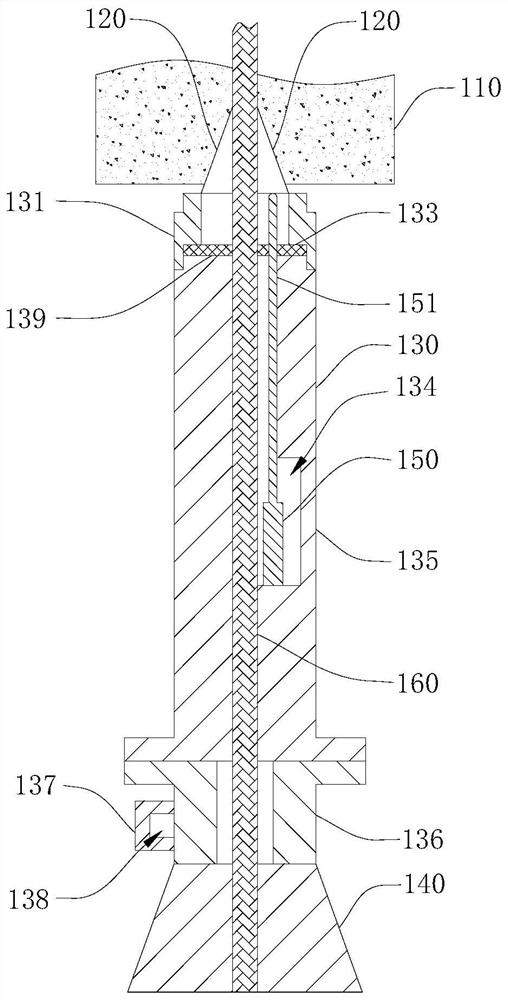

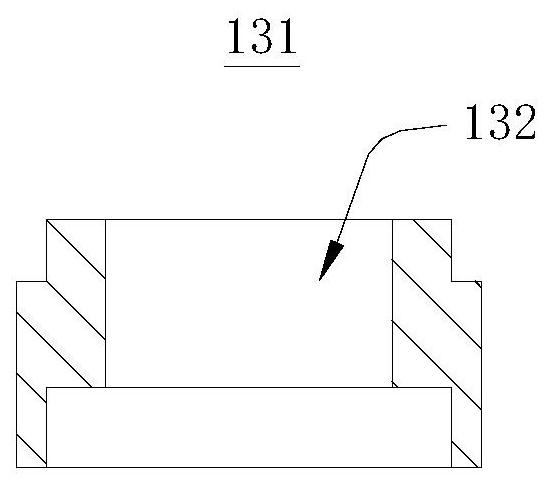

[0034] Please refer to figure 2 and image 3 , a multi-point independent displacement detection device for steel strand clips used in the reverse pull method, including: a limit cylinder 130, a tension jack 140 and a host controller, the clip 120 to be tested is fixed in the anchorage 110, and the limit One end of the barrel 130 faces the clip 120 , and the other end of the limiting barrel 130 is connected with the tension jack 140 . The steel strand 160 is sequentially connected to the anchorage 110, the clip 120, the limit cylinder 130 and the tension jack 140, the steel strand 160 is fixedly connected to the anchor 110, the clip 120 and the tension jack 140, and the steel strand 160 runs through There is a gap between the limiting cylinder 130 and the inner wall of the limiting cylinder 130 . The host controller communicates with the displacement sensor 150 and the tension jack 140 respectively, and the tension jack 140 is started and stopped by the host controller.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com