Displacement monitoring system and method for mine hoisting equipment

A displacement monitoring and equipment technology, applied in elevators, measuring devices, instruments, etc., can solve problems such as threatening the safety of the lifting process, affecting the stability of the lifting process, and the fatigue life of steel wire ropes, and achieve the effect of improving the degree of safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0112] Figure 4 It is a schematic diagram of a mine multi-rope friction hoist steel wire rope online monitoring system in an embodiment of the present invention, as Figure 4 As shown, the mine multi-rope friction hoist wire rope online monitoring system includes a laser scanner 15, an image acquisition device, a synchronous acquisition device 5, a power box 6, a signal transmitter 7, a signal receiver 8, a monitoring display 11 and an industrial computer 13.

[0113] Here, the mine multi-rope friction hoist steel wire rope on-line monitoring system is used to monitor the steel wire rope 16 of the hoist wire rope. The mine 18 moves up and down for transporting goods or miners; in order not to affect the operation of the multi-rope friction hoist in the mine, the online monitoring system will be far away from the mine 18 by a preset distance, and the farthest can reach more than 100 meters.

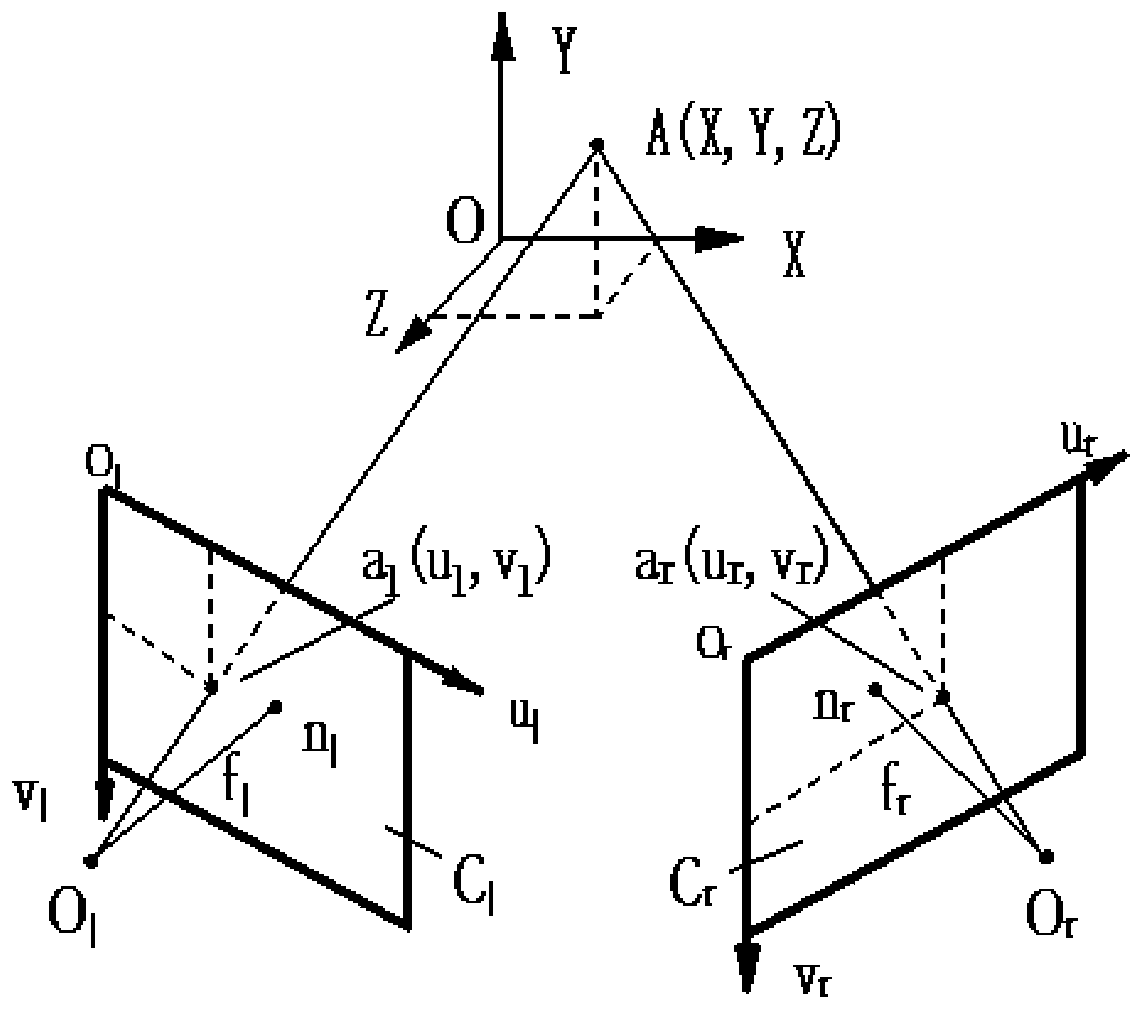

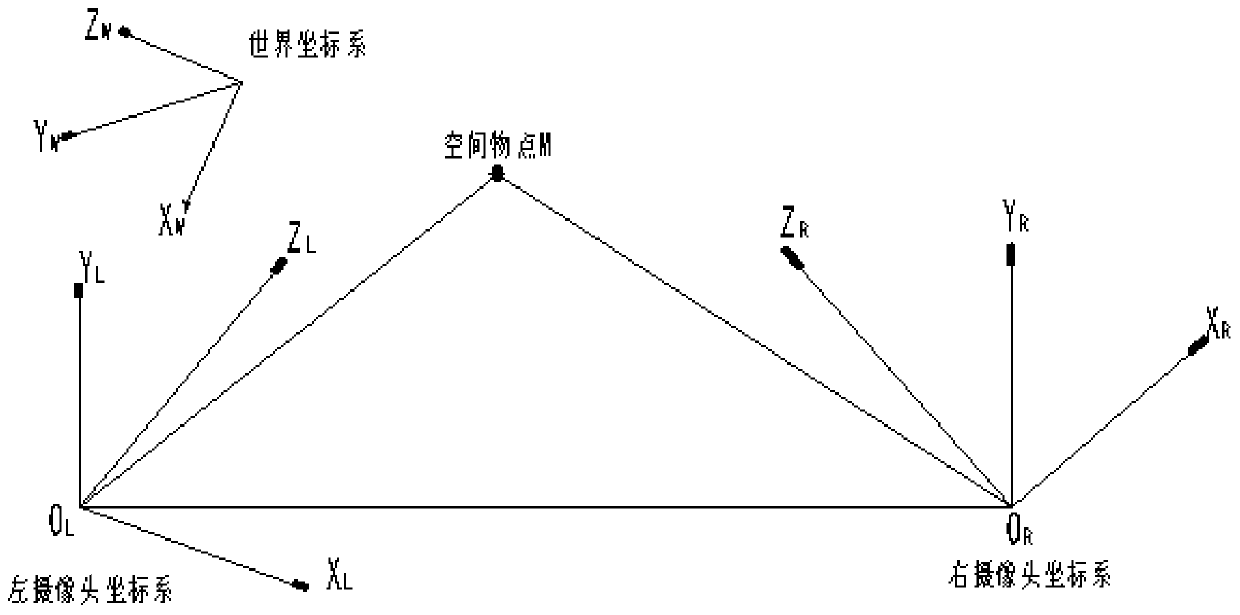

[0114] The laser scanner 15 can help the image processing device to quickly determi...

Embodiment 2

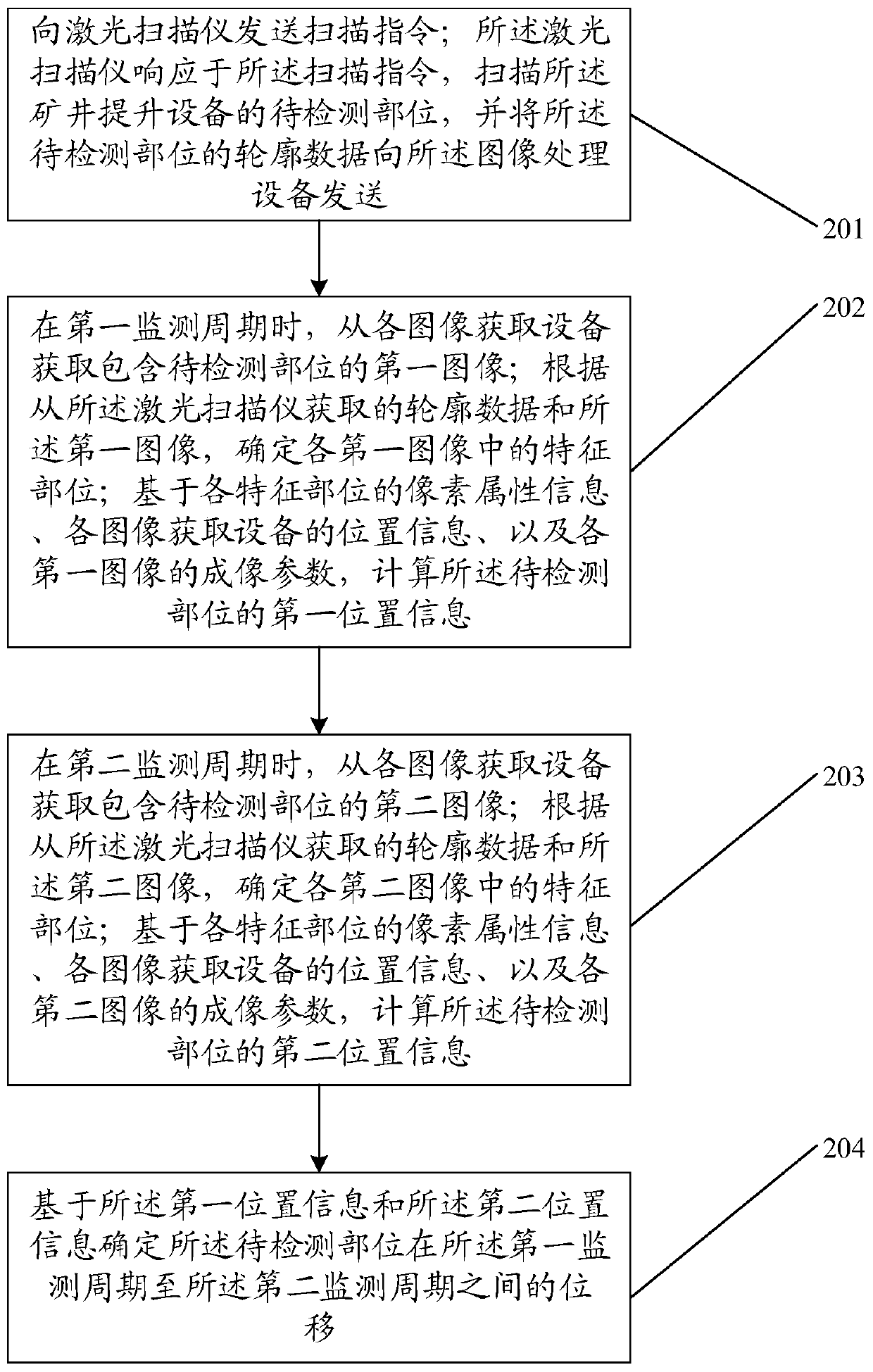

[0140] Figure 9 It is a schematic flow chart of the mine multi-rope friction hoist steel wire rope online monitoring method in the second embodiment of the present invention, as Figure 9 As shown, the displacement monitoring method of the mine hoisting equipment includes the following steps:

[0141] Step 500: camera calibration and correction;

[0142] Before acquiring images, the left and right cameras are calibrated and corrected to eliminate the image distortion caused by the camera itself.

[0143] Step 501: static marker acquisition;

[0144] Take pictures of static markers when the wire rope is not running to obtain a ruler.

[0145] Step 502: laser scanning;

[0146] scanning the profile of the steel wire rope of the hoist to obtain profile data of the steel wire rope of the hoist.

[0147] Step 503: video stream shooting and transmission;

[0148] After the monitoring starts, the running video of the steel wire rope is taken and transmitted to the industrial c...

Embodiment 3

[0167] Figure 10 It is a schematic diagram of the online monitoring system of the sky wheel of the mine multi-rope friction hoist three in the embodiment of the present invention, as Figure 10 As shown, the mine multi-rope friction hoist top wheel online monitoring system includes image acquisition equipment, industrial computer 67, signal transmitter 68, signal receiver 69, monitoring host 70, sound and light alarm 71 and printer 72.

[0168] Wherein, the image acquisition device includes an industrial camera, an LED lighting lamp 65 and a stereo target 66 , and the industrial camera includes a first camera 61 , a second camera 62 , a third camera 63 and a fourth camera 64 .

[0169] The first camera 61, the second camera 62, the third camera 63 and the fourth camera 64 are used to shoot the working video of the sky wheel;

[0170] The LED illuminating lamp 65 is used to increase the brightness of the sky wheel surface, so that the industrial camera can be photographed mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com