Reliability design method of high-speed press force-applying components considering multi-type uncertainties

A force-applying component and uncertainty technology, which is applied in the field of reliability design of force-applying components of high-speed presses, can solve problems such as reliability design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with accompanying drawing and example.

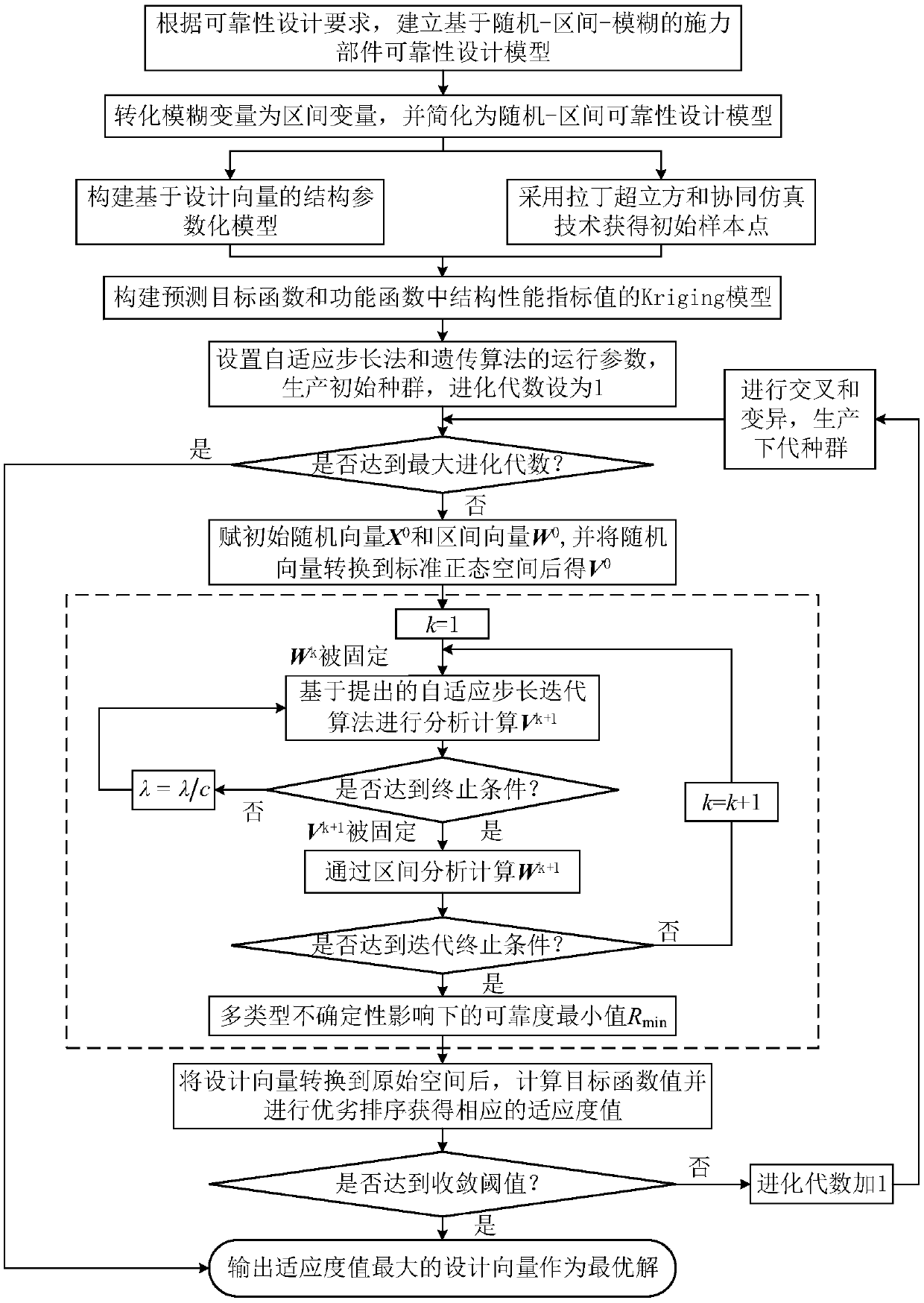

[0051] The information involved in the figure is the actual application data of the present invention in the reliability design of the force-applying parts of a certain type of high-speed press, figure 1 It is a flow chart of reliability design of high-speed press force components considering random, interval and fuzzy uncertainties.

[0052] 1. Establishment of a reliability design model for force-applying components based on random-interval-fuzzy

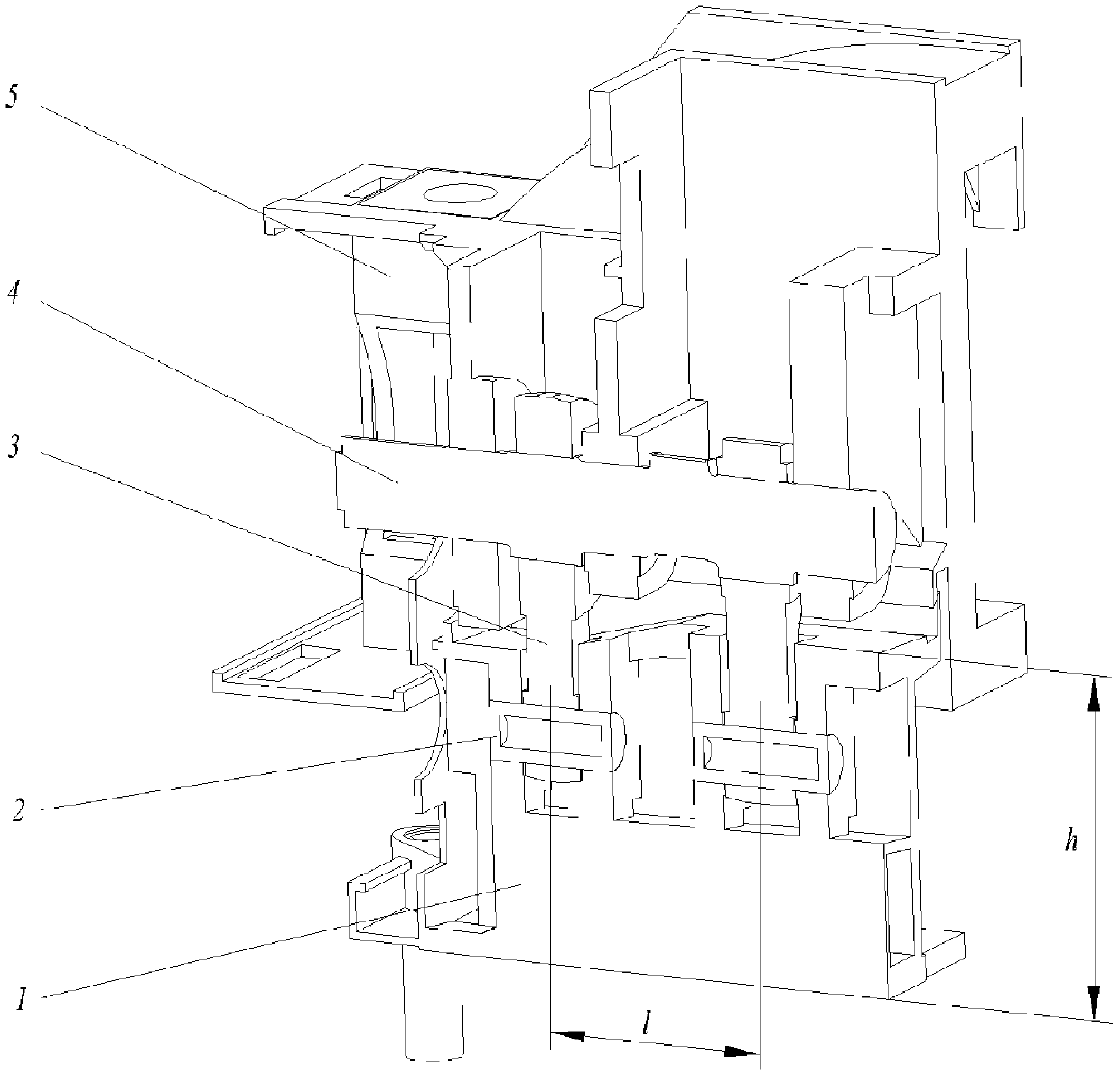

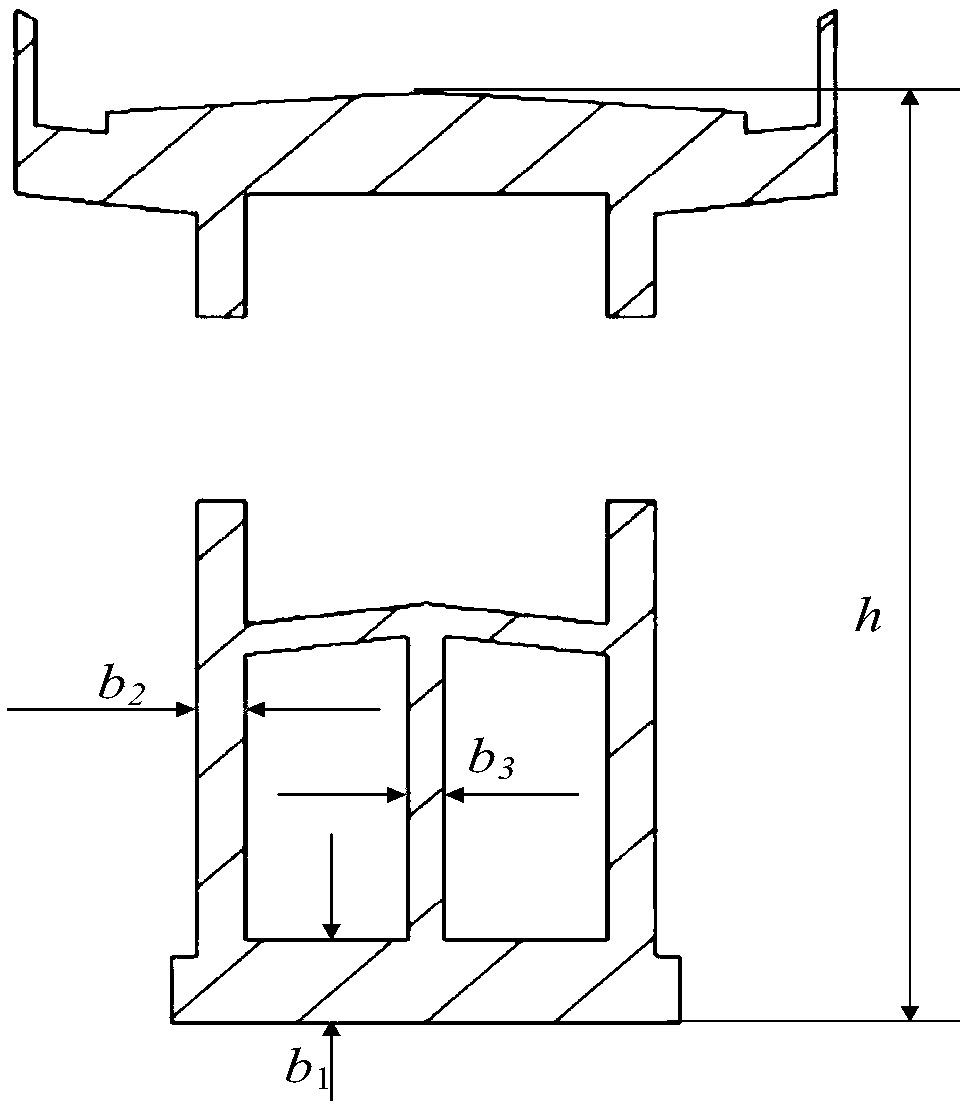

[0053] The force application parts of the high-speed press of model 300L4 are selected as the research object, such as figure 2 As shown, 1 is the slider, 2 is the pin, 3 is the lower connecting rod, 4 is the main shaft, 5 is the upper beam, l represents the distance between the connecting rods, and h represents the height of the slider. The cross-sectional view and design parameters of the force-applying parts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com