A continuously connected pre-insulated terminal and a connecting method thereof

An insulating terminal and metal terminal technology, which is applied in the direction of connection, conductive connection, electrical component connection, etc., can solve the problems of insufficient flatness at the splicing point, complicated steps, unfavorable installation and use, etc., and achieves simple structure, simple production process, and connecting material with smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

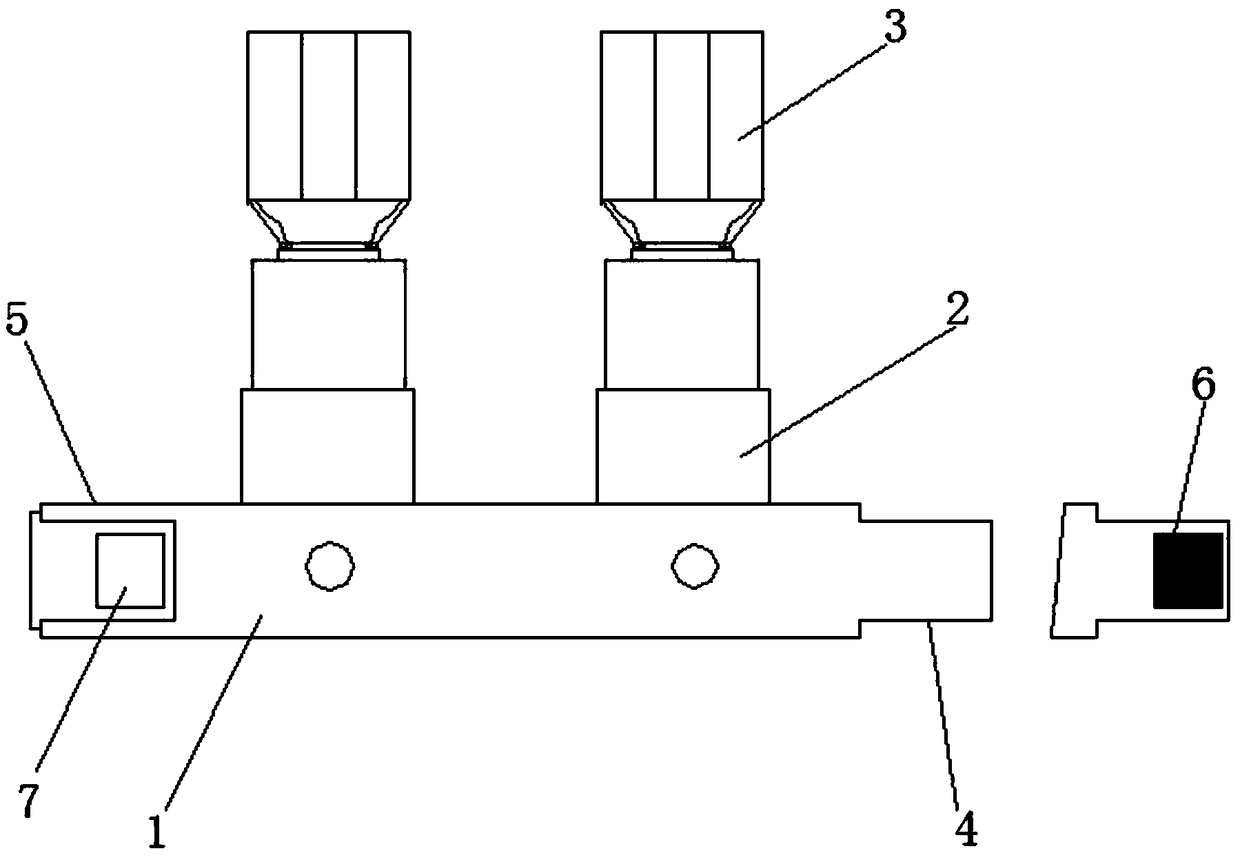

[0032] The invention discloses a continuously connected pre-insulated terminal, which comprises a plurality of unit insulated terminals connected end to end to form a continuous pre-insulated terminal, and the unit insulated terminal is composed of a plastic strip 1, a fixing hole 2. Composed of metal terminals 3, the plastic strip 1 is a plastic strip, the fixing hole 2 is fixed on the plastic strip 1, and the fixing hole 2 and the plastic strip 1 are integrally formed by injection molding during production , the metal terminal 3 is fixed inside the fixing hole 2, the two ends of the plastic strip 1 are injection molded, and the two ends are respectively a male head 4 and a female head 5, and the male head 4 is a riveted post structure, the female head 5 is a riveting hole structure, the male head 4 and the female head 5 are matched with each other, the male head 4 of the insulated terminal of the previous unit is embedded in the female head 5 of the insulated terminal of the ...

Embodiment 2

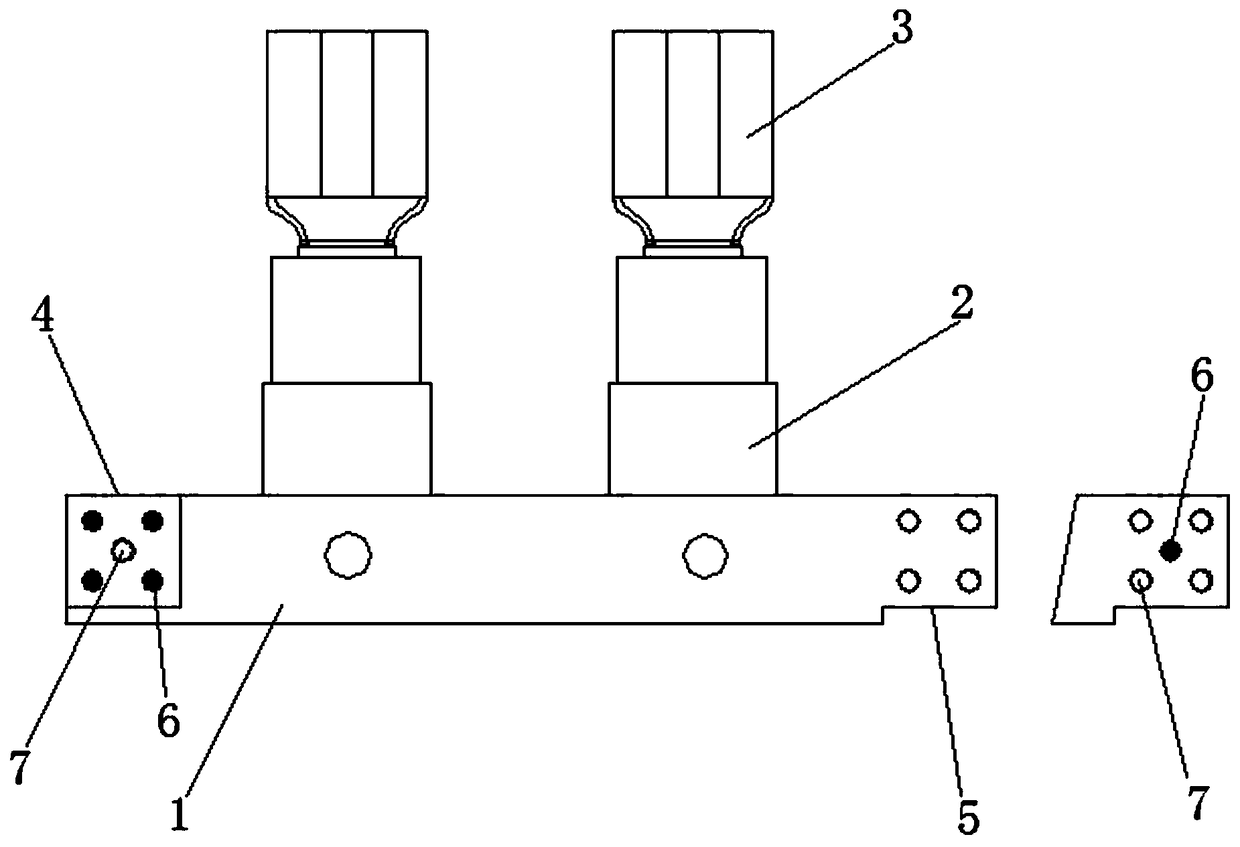

[0036] The invention discloses a continuously connected pre-insulated terminal, which comprises a plurality of unit insulated terminals connected end to end to form a continuous pre-insulated terminal, and the unit insulated terminal is composed of a plastic strip 1, a fixing hole 2. Composed of metal terminals 3, the plastic strip 1 is a plastic strip, the fixing hole 2 is fixed on the plastic strip 1, and the fixing hole 2 and the plastic strip 1 are integrally formed by injection molding during production , the metal terminal 3 is fixed inside the fixing hole 2, the two ends of the plastic strip 1 are injection molded, and the two ends are respectively a male head 4 and a female head 5, and the male head 4 is a riveted post structure, the female head 5 is a riveting hole structure, the male head 4 and the female head 5 are matched with each other, the male head 4 of the insulated terminal of the previous unit is embedded in the female head 5 of the insulated terminal of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com