A control gate circuit of a pumping unit

A technology for controlling brakes and pumping units, which is applied to electric motors/converter plugs, deceleration devices of AC motors, etc., can solve problems such as slipping cars, poor load, etc., to improve safety, simple circuits, and meet work performance requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

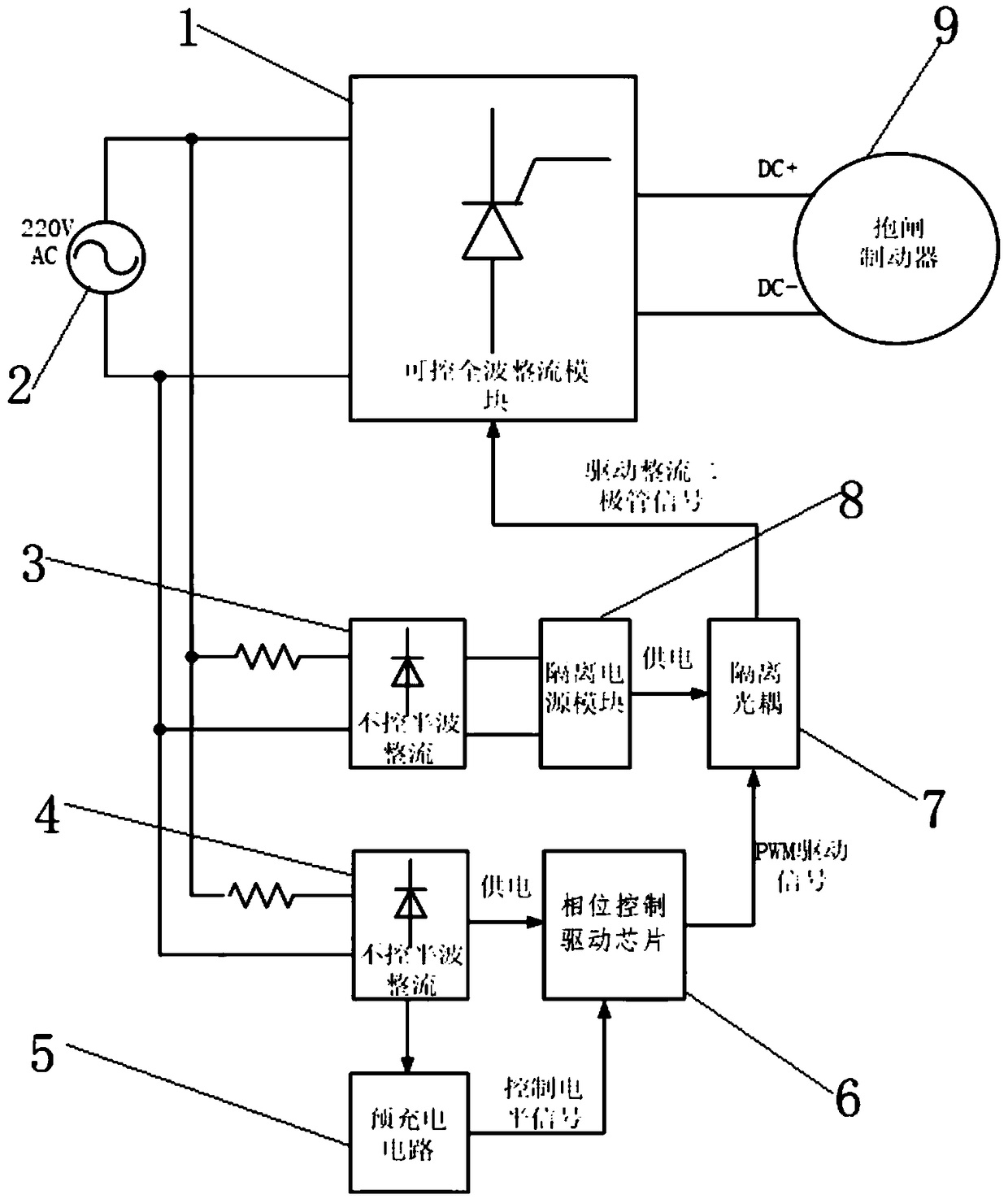

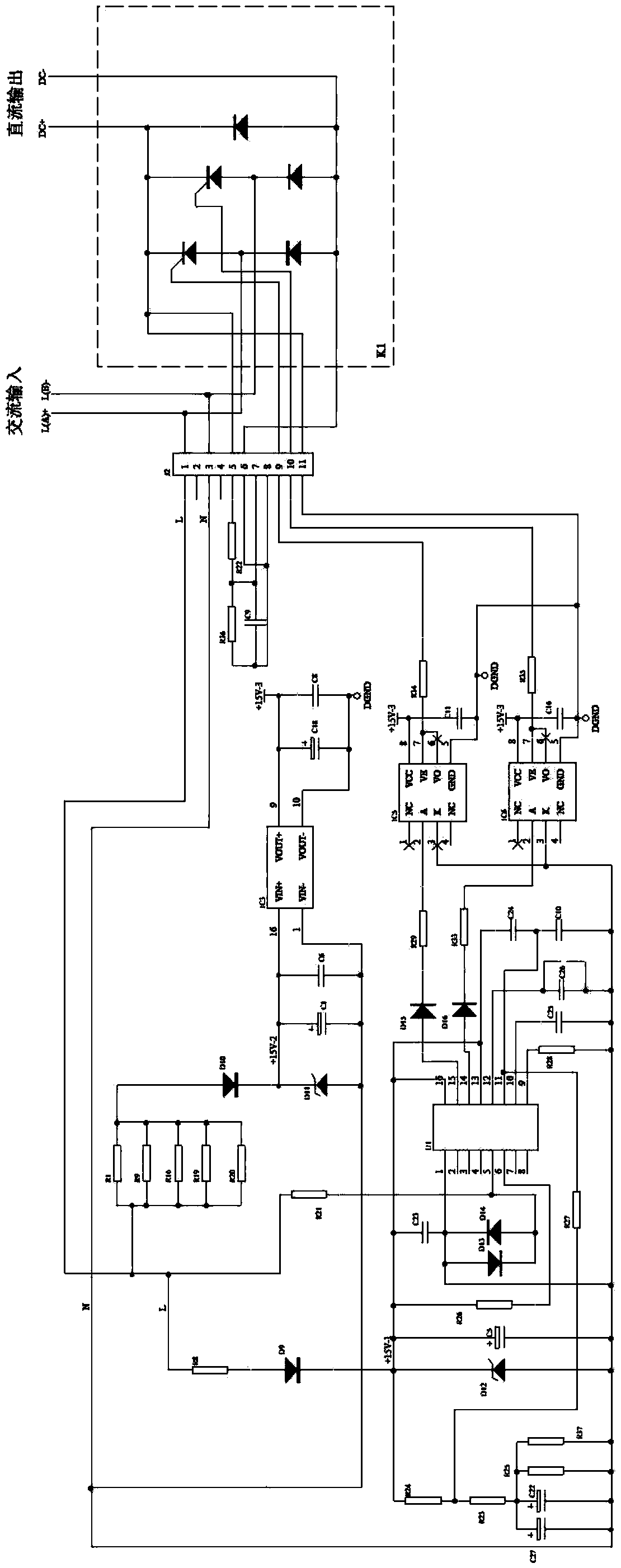

[0021] A pumping unit control gate circuit of the present invention, the structure is as follows figure 1 and figure 2 As shown, it includes a power supply 2, a phase control drive chip 6 and a brake 9, and the phase control drive chip 6 is respectively connected with a second uncontrolled half-wave rectifier module 4, a pre-charging circuit 5, an isolated optocoupler 7, and an isolated optocoupler 7 The isolated power module 8 and the controllable full-wave rectification module 1 are respectively connected, the isolated power module 8 is connected with the first uncontrolled half-wave rectification module 3, the controllable full-wave rectification module 1 is connected with the brake 9, and the controllable full-wave The rectification module 1 , the first uncontrolled half-wave rectification module 3 , and the second uncontrolled half-wave rectification module 4 are all connected to the power supply 2 .

[0022] The pre-charging circuit 5 is composed of resistors R23, R24,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com