Front fender structure of a motor vehicle

A technology for front fenders and motor vehicles, which is applied to vehicle components, superstructures, and subassemblies of superstructures, etc., can solve the problems of limited energy absorption potential, reduced retention rigidity of fenders, and reduced passive safety performance. Control maintenance costs, reduce thickness, and achieve the effect of weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

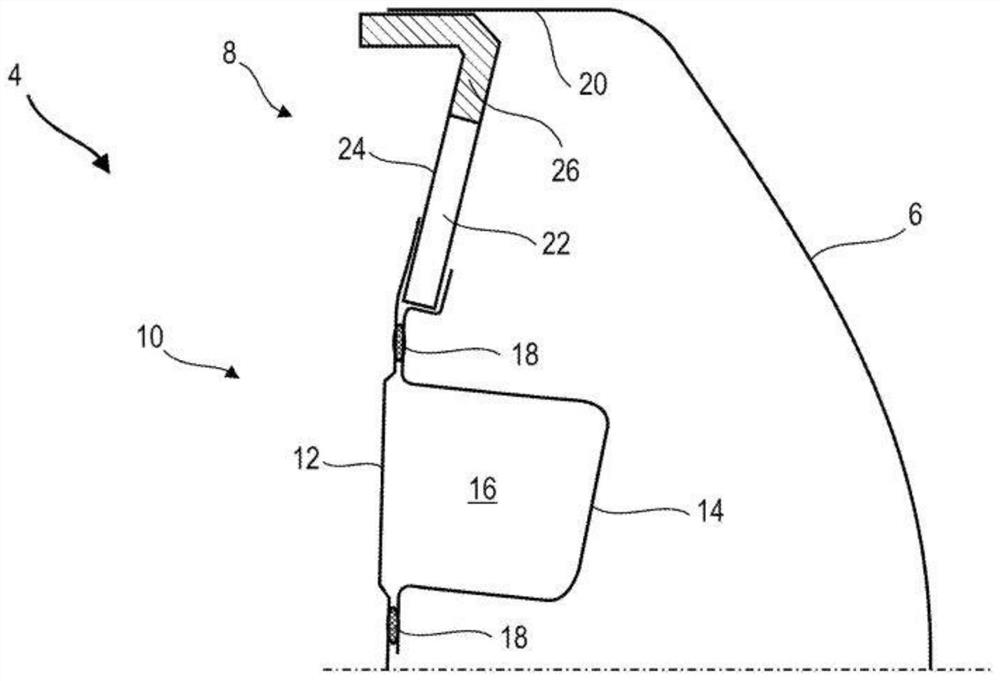

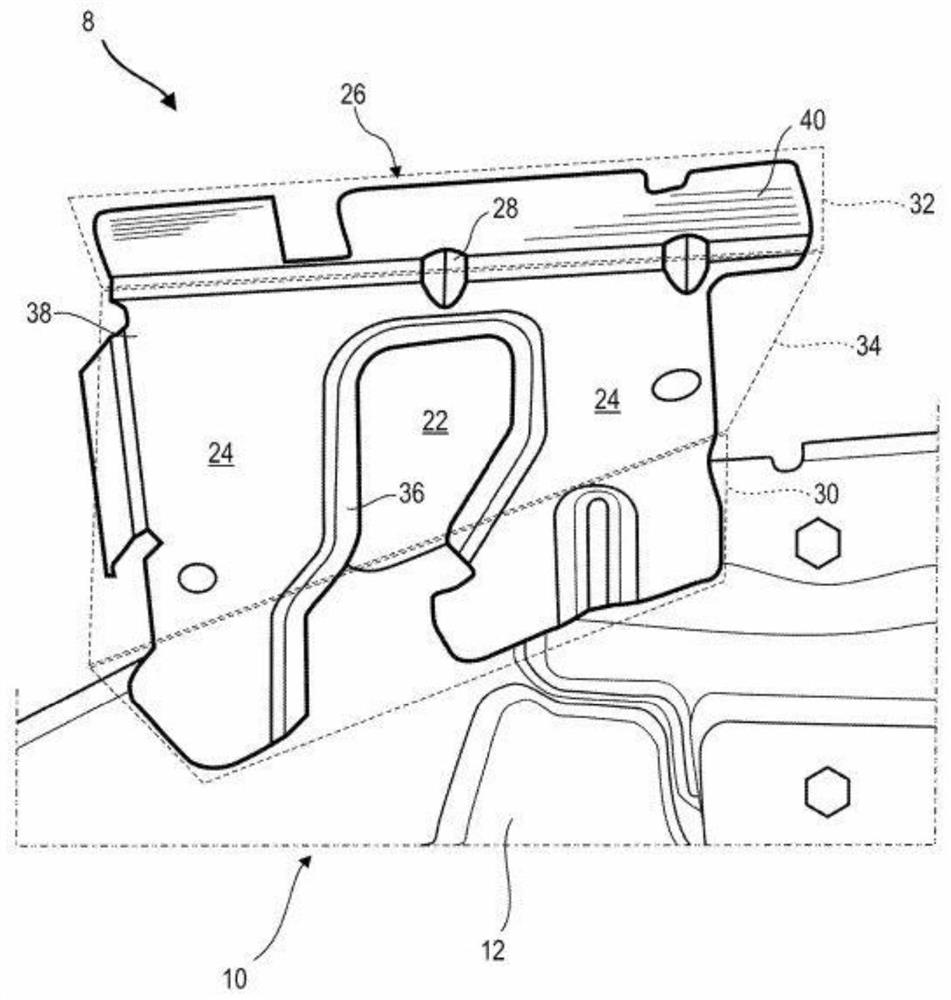

[0039] In the following description, the longitudinal direction corresponds to the main direction of movement of the vehicle, and the front corresponds to its main direction of movement. The lateral direction is perpendicular to the lateral direction. The orientations mentioned below refer to the normal installation orientation in the vehicle.

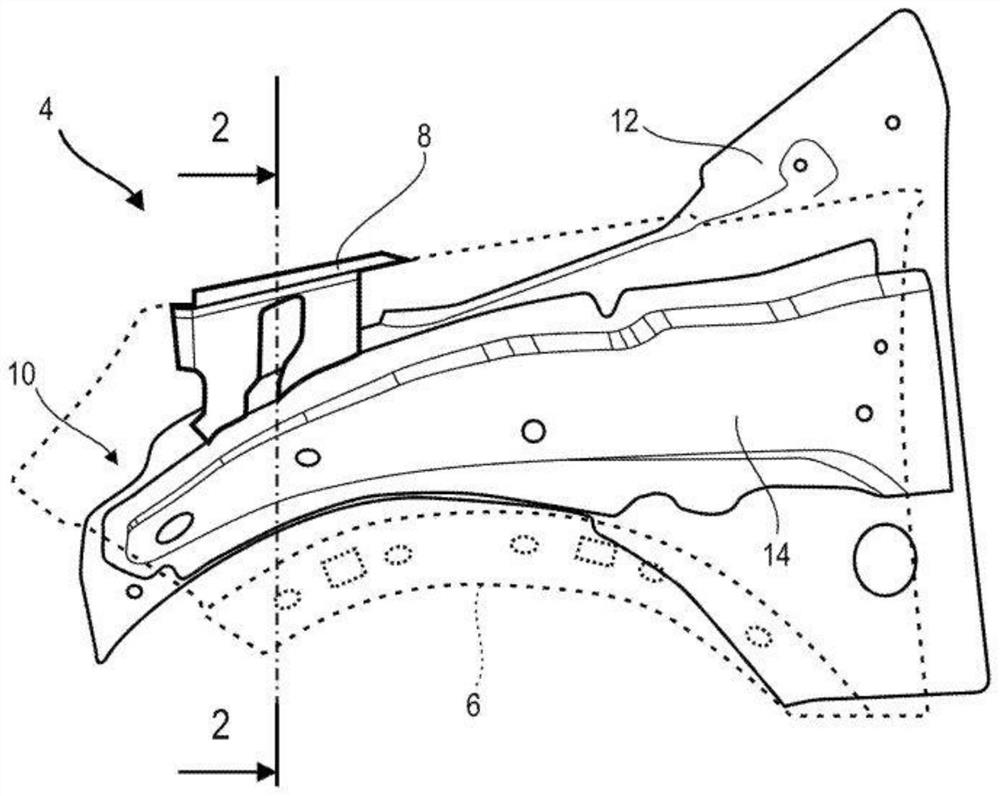

[0040] figure 1 A front part 4 of the structure of a vehicle, in particular a motor vehicle, is shown. The front portion is viewed laterally from outside the vehicle. The front part corresponds to the front left part. Of course, the invention is also applicable to the front right part.

[0041] The structure may be the body of a motor vehicle, the body consisting of a joint of sheet metal which is stamped and then welded or glued to each other to form the frame of the vehicle. The frame supports various equipment of the vehicle including wheels (not shown), engine (not shown). This frame connects the front bumper to the rear bump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com