Conveyor belt

A technology of rubber layer and canvas, which is applied in the field of conveying belts, can solve the problems of surface pollution or modification, and achieve the effect of excellent non-adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach >

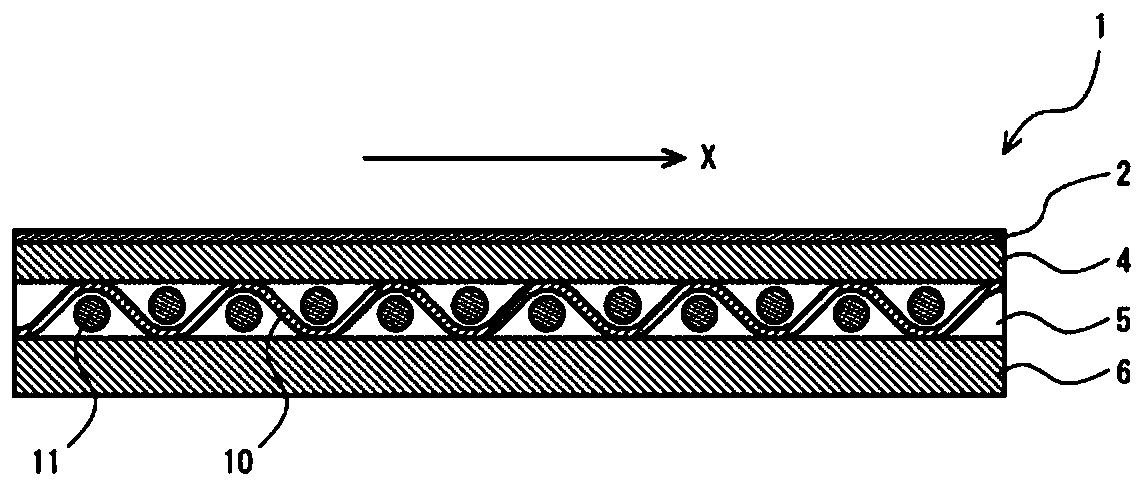

[0023] [carrying belt]

[0024] figure 1 It is a schematic sectional view of the conveyance belt 1 which concerns on 1st Embodiment of this invention. The conveying belt 1 uses a canvas 5 as a core body. The conveyance belt 1 includes a canvas 5 , a first rubber layer 4 laminated on one surface of the canvas 5 , and a cover layer 2 laminated on the surface of the first rubber layer 4 opposite to the canvas 5 . In the said conveyance belt 1, the cover layer 2 becomes an outermost layer. Furthermore, the second rubber layer 6 is laminated on the surface of the canvas 5 opposite to the first rubber layer 4 .

[0025] The conveyance belt 1 is rotated in conjunction with pulleys by a drive mechanism not shown so that the coating layer 2 is on the outside. Therefore, the outer surface of the coating layer 2 becomes the conveyance surface.

[0026] (canvas)

[0027] The conveying belt 1 uses a canvas 5 as a core body. The canvas 5 maintains the tension applied to the conveyanc...

Embodiment approach

[0077] It should be thought that embodiment disclosed this time is an illustration and not restrictive at all points. The scope of the present invention is not limited to the configuration of the above-described embodiments but is shown by the claims, and it is intended that all changes within the meaning and scope equivalent to the claims are included.

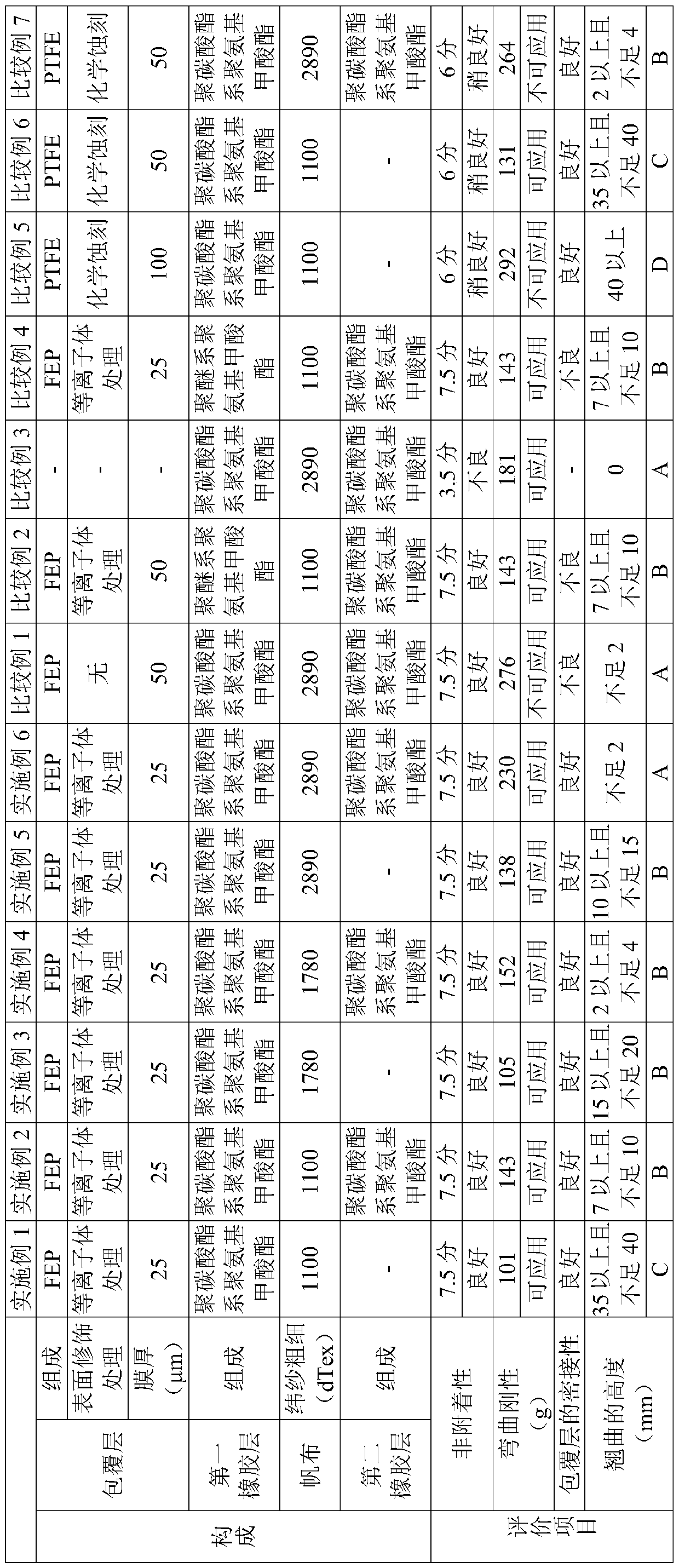

Embodiment 1~ Embodiment 6 and comparative example 1~ comparative example 7

[0081]Regarding Examples 1 to 6 and Comparative Examples 1 to 7, the resins for forming the cover layer shown in Table 1 and polyurethane for forming the first rubber layer and the second rubber layer were produced as materials. carrying belt. In Example 1 to Example 6 and Comparative Examples 1 to 7, a conveyor belt was produced based on the manufacturing method of the above-mentioned conveyor belt. First, by extrusion lamination, polyurethane as a composition for forming a first rubber layer is melt-extruded into a film and bonded under pressure on a canvas to integrate them to form a substrate for forming a substrate. laminated body. Next, the substrate-forming laminate and the coating layer film mainly composed of a coating layer-forming fluororesin were thermocompression-bonded by drum vulcanization at 155° C., and then cooled. Next, polyurethane, which is a composition for forming a second rubber layer, is melt-extruded into a film form on the surface of the canvas of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com