Spring round steel two-end cone type pressing device

A round steel, cone-shaped technology, which is applied in the field of conical pressing devices at both ends of spring round steel, can solve the problems of high cost of daily maintenance and maintenance, difficulty in troubleshooting, etc., and achieve low maintenance costs, small vibration, and large single-stage speed ratio Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

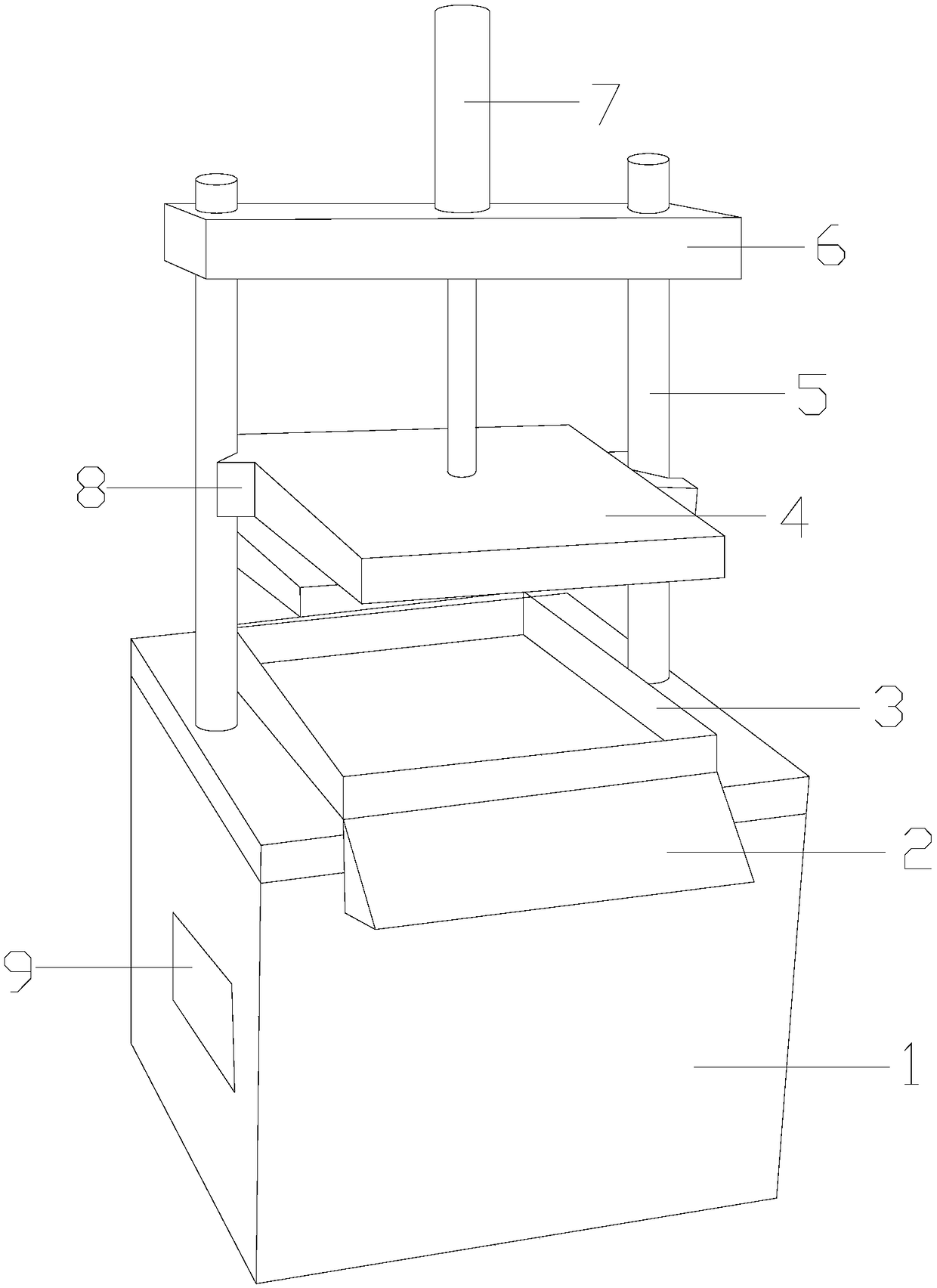

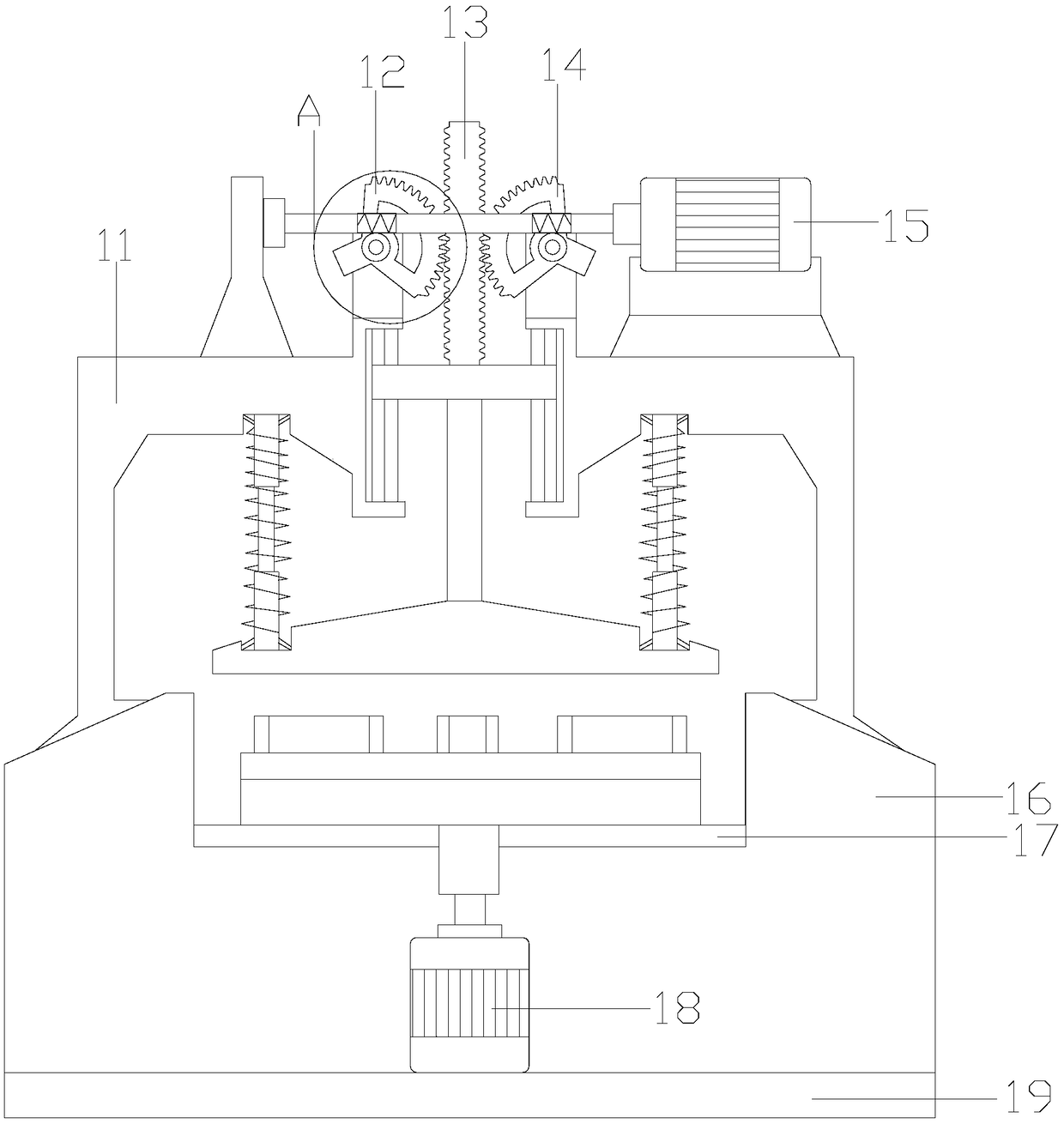

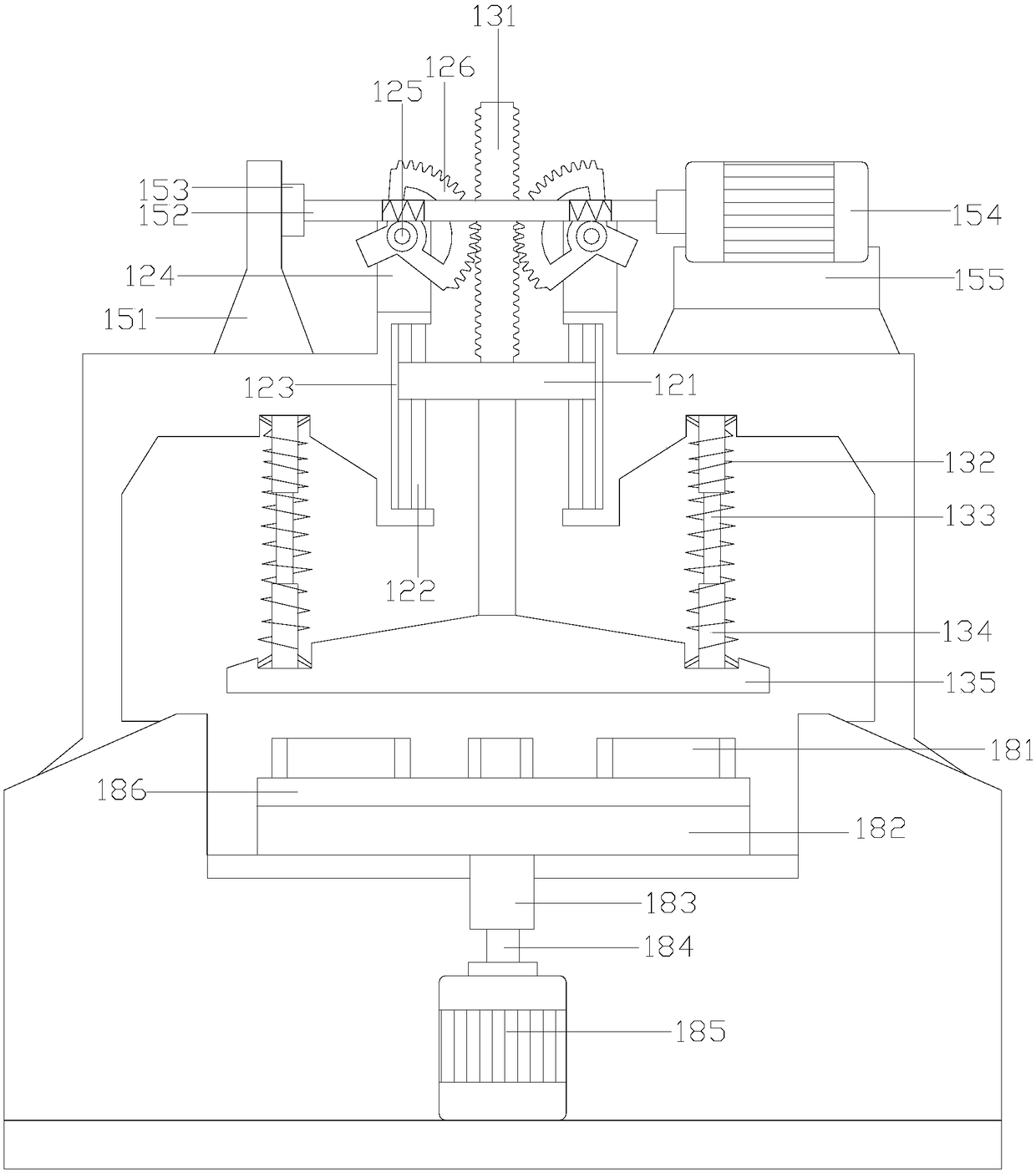

[0023] Such as Figure 1-Figure 5 As shown, the present invention provides a spring round steel tapered pressing device at both ends, the structure of which includes a convenient and efficient pressing mechanism 1, a guide plate 2, a limit pressure frame 3, an upper pressing plate 4, a guide post 5, a top plate 6, a filter press Cylinder 7, guide slider 8, outlet 9, the left side of the convenient and efficient pressing mechanism 1 is fixedly provided with a movable installation outlet 9 and the two are integrally formed structures, the guide plate 2 is a triangular structure, the The rear end of the guide plate 2 is fixedly welded to the front end of the limit pressure frame 3 and welded together with the convenient and efficient pressing mechanism 1. The guide post 5 is provided with two and the bottoms are respectively welded on both sides of the upper end of the convenient and efficient pressing mechanism 1. The top plate 6 is horizontally arranged on the upper ends of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com