Multi-linkage valve

A technology of multi-valve and valve main body, applied in the field of multi-valve, can solve the problems of increasing the volume of multi-valve, complex on-site installation, unreliability, etc. The effect of structural firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

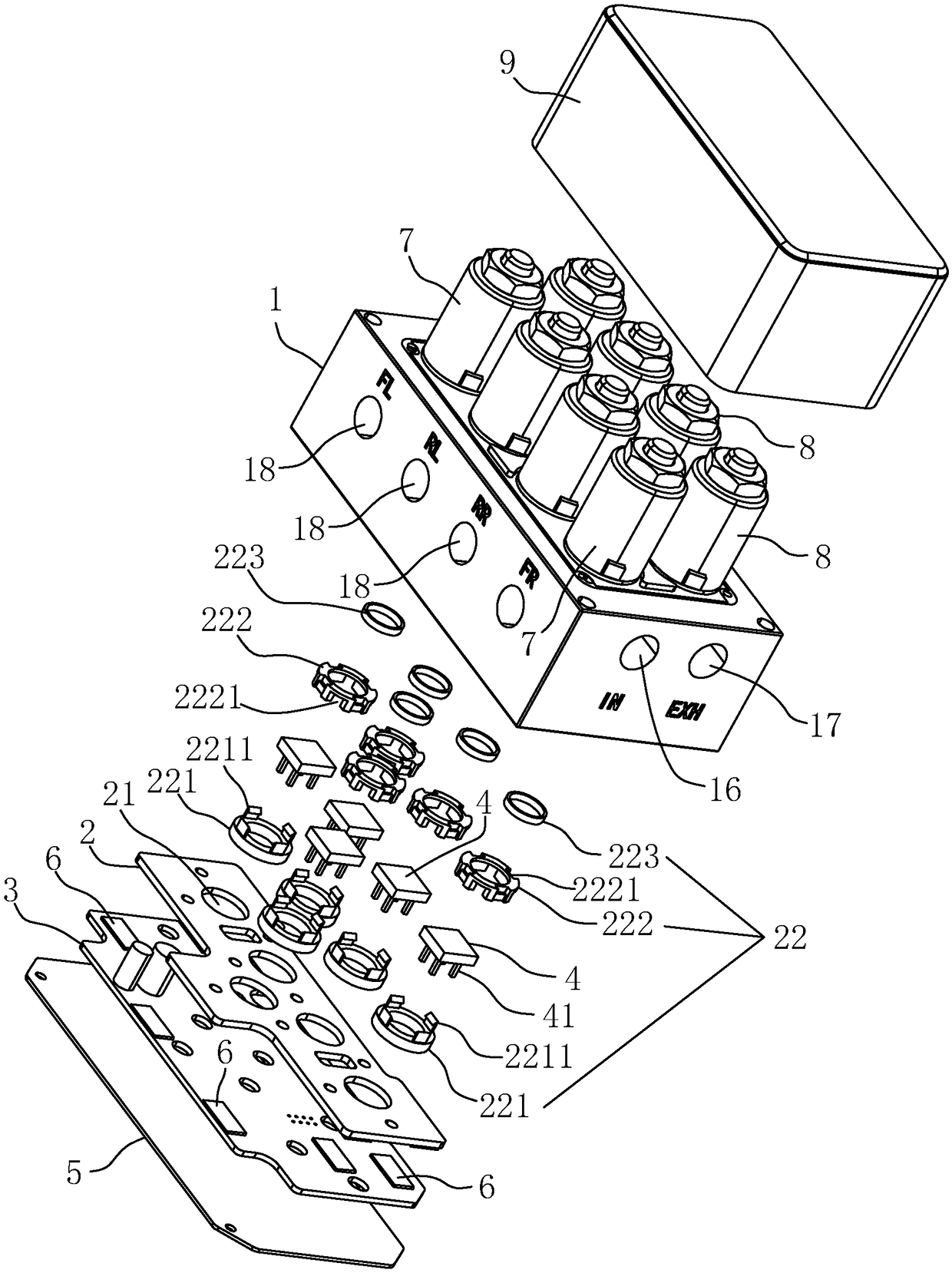

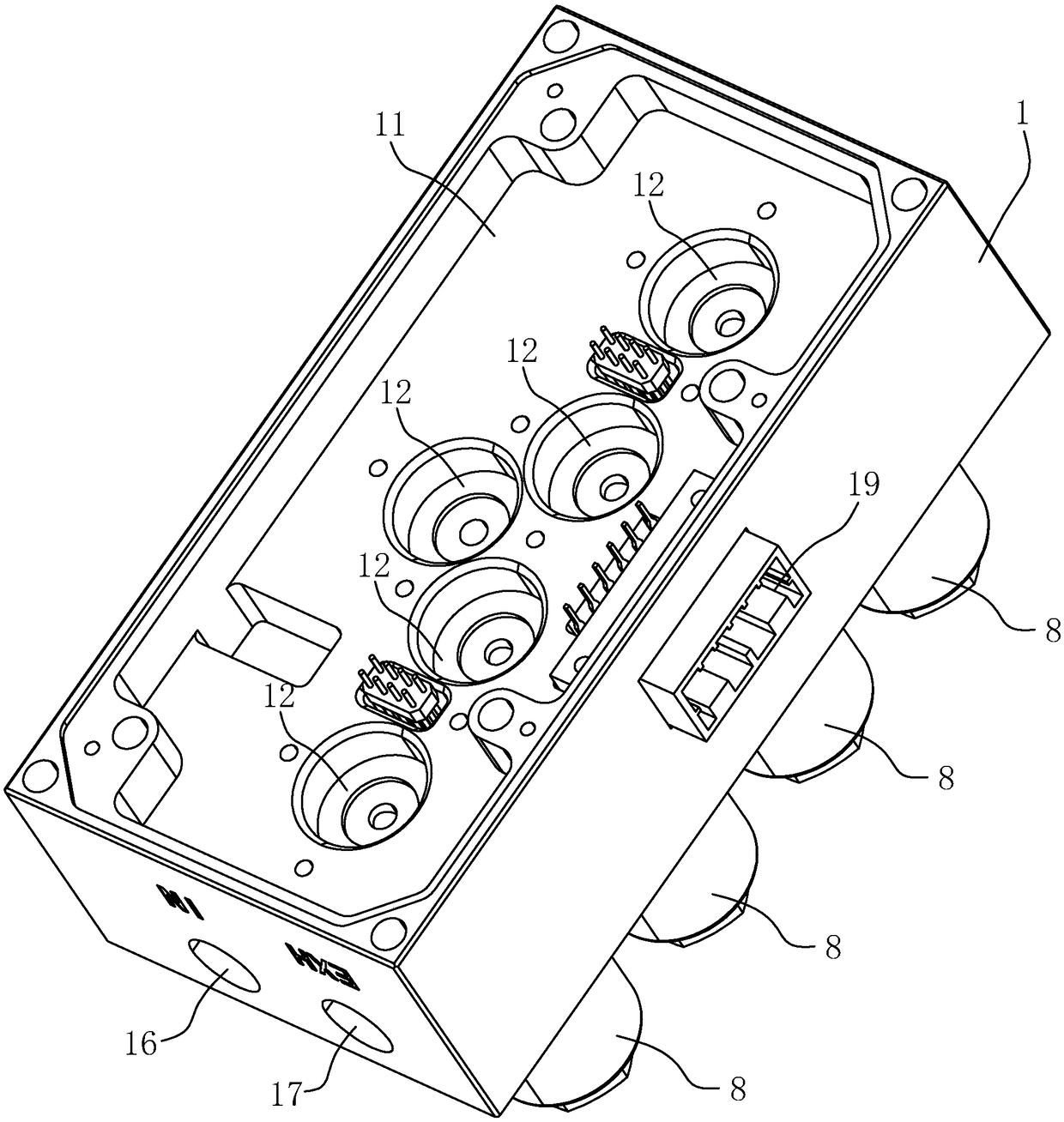

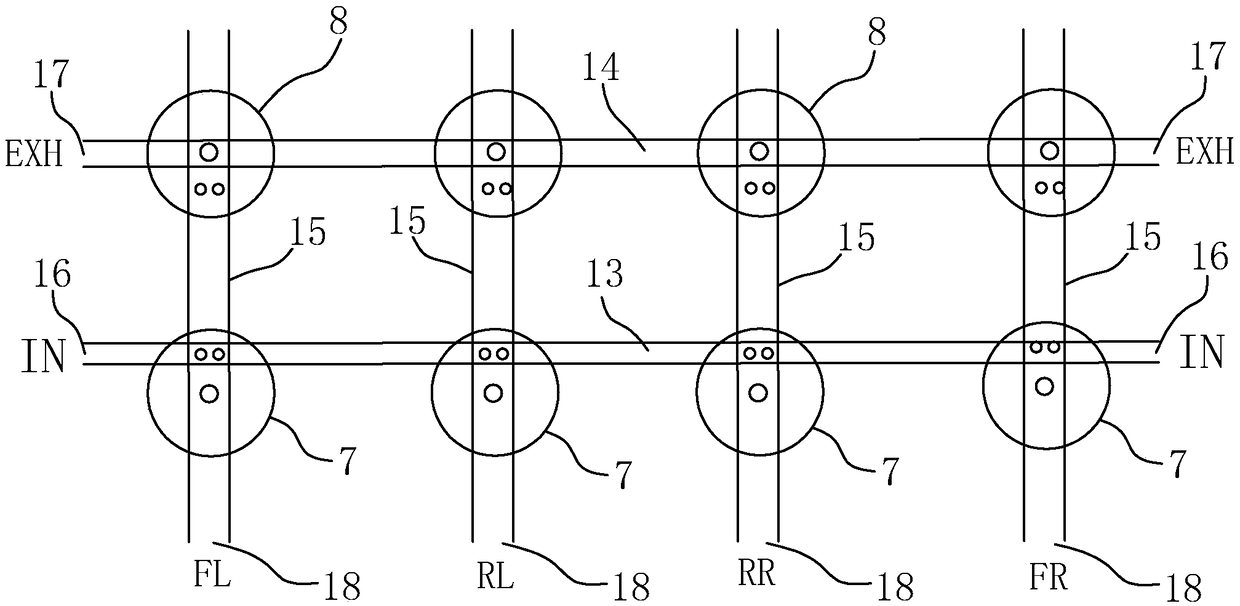

[0040] A manifold valve, combined with figure 1 with figure 2 As shown, it includes: valve main body 1, mounting plate 2, control circuit board 3, pressure sensor 4, cover plate 5, sponge pad 6, inlet solenoid valve 7, outlet solenoid valve 8 and protective cover 9.

[0041] The surface of the valve body 1 is provided with a concave cavity 11, and the bottom wall of the concave cavity 11 is provided with five counterbore holes 12. In other embodiments, the number of counterbore holes 12 can be increased or decreased adaptively, and can be two, three, or four. one, six or more; the mounting plate 2 is arranged in the concave cavity 11, the mounting plate 2 has a through hole 21, the mounting seat 22 is located on the mounting plate 2, and the positions and numbers of the mounting seat 22 and the through hole 21 are uniform. It is arranged corresponding to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com