A tensile flame retardant silicone rubber cable

A flame-retardant, silicone rubber technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of no buffer device, easy damage of cables, complex structure, etc., to avoid severe extrusion, increase service life, and increase stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

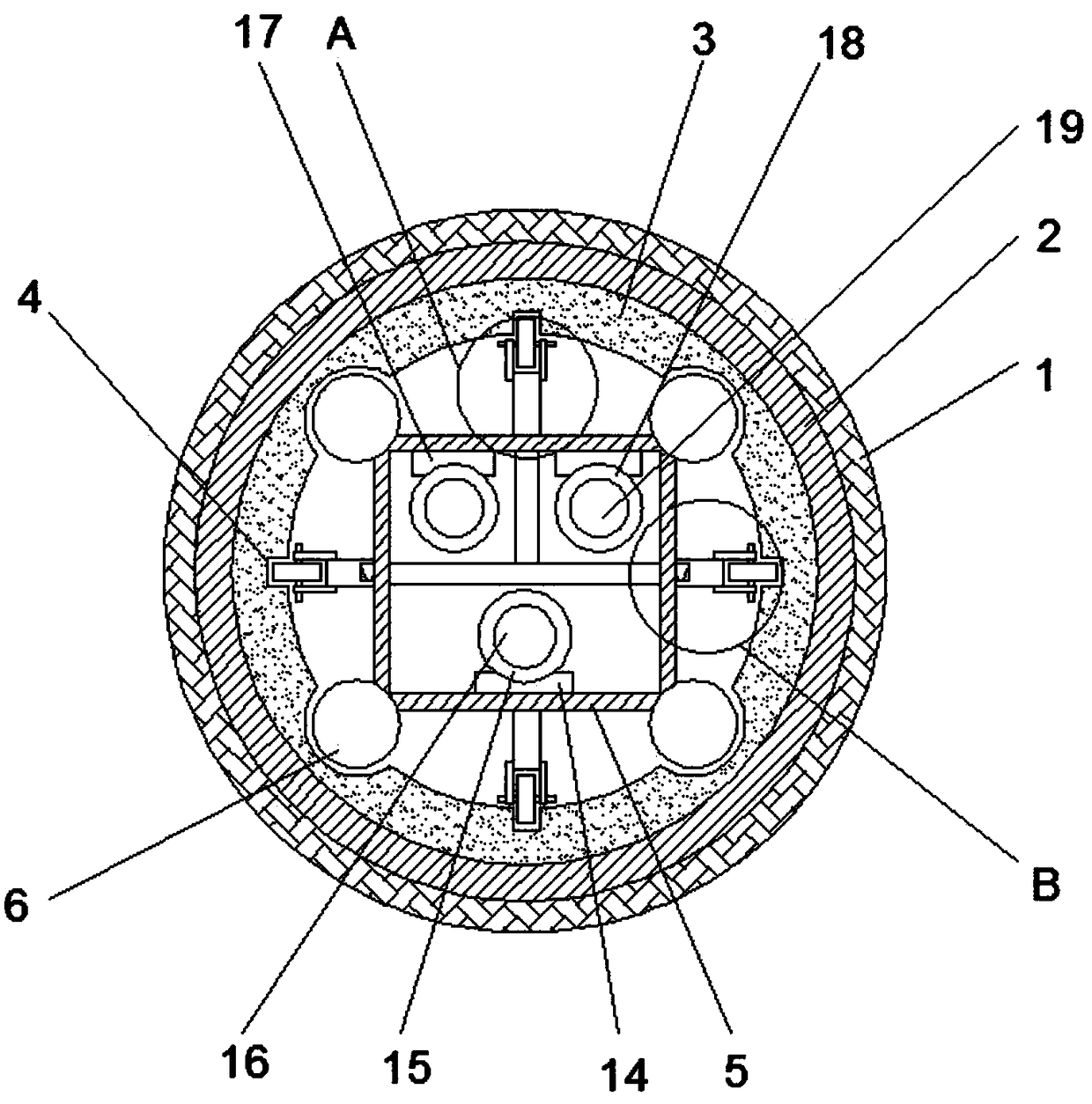

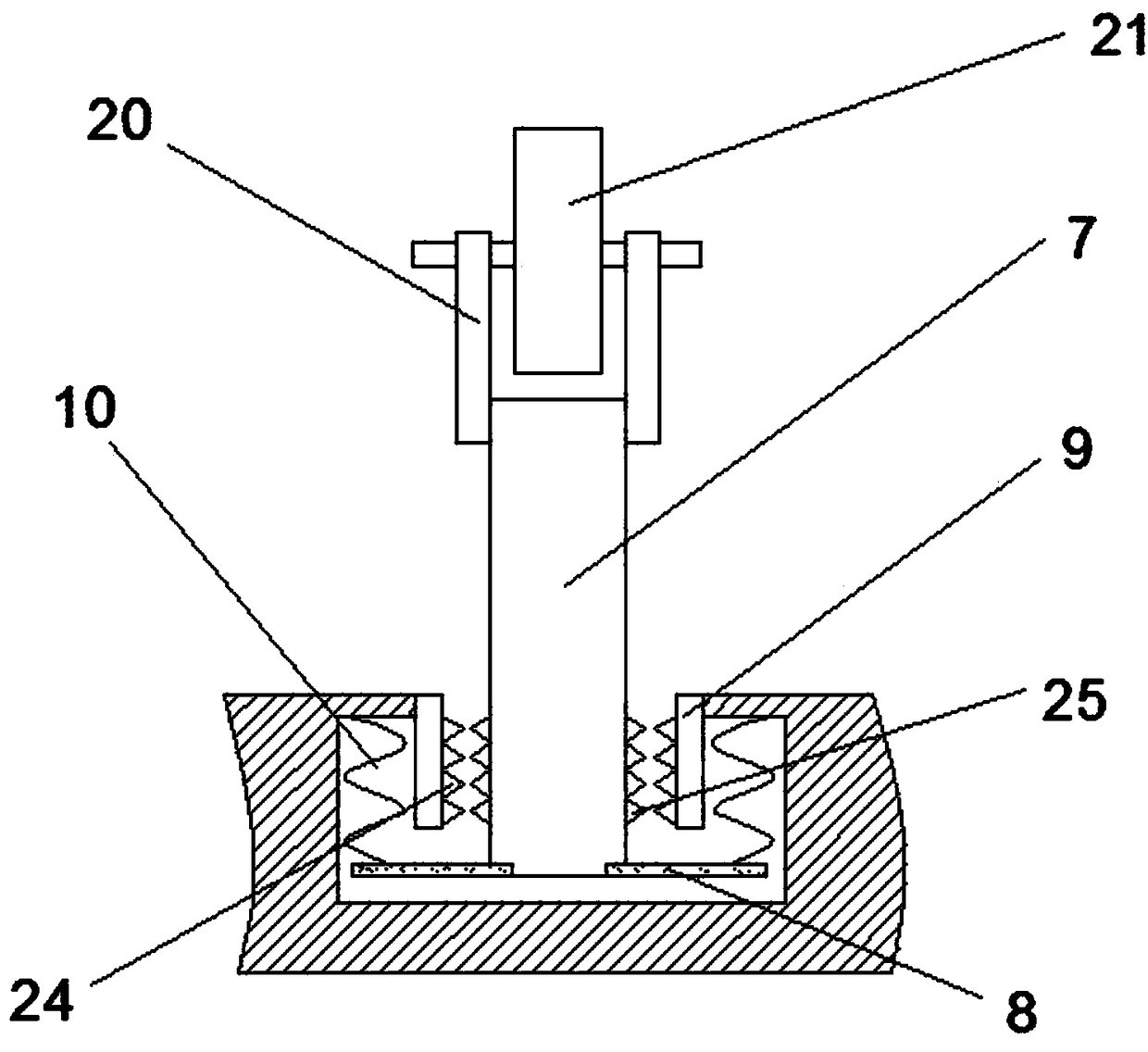

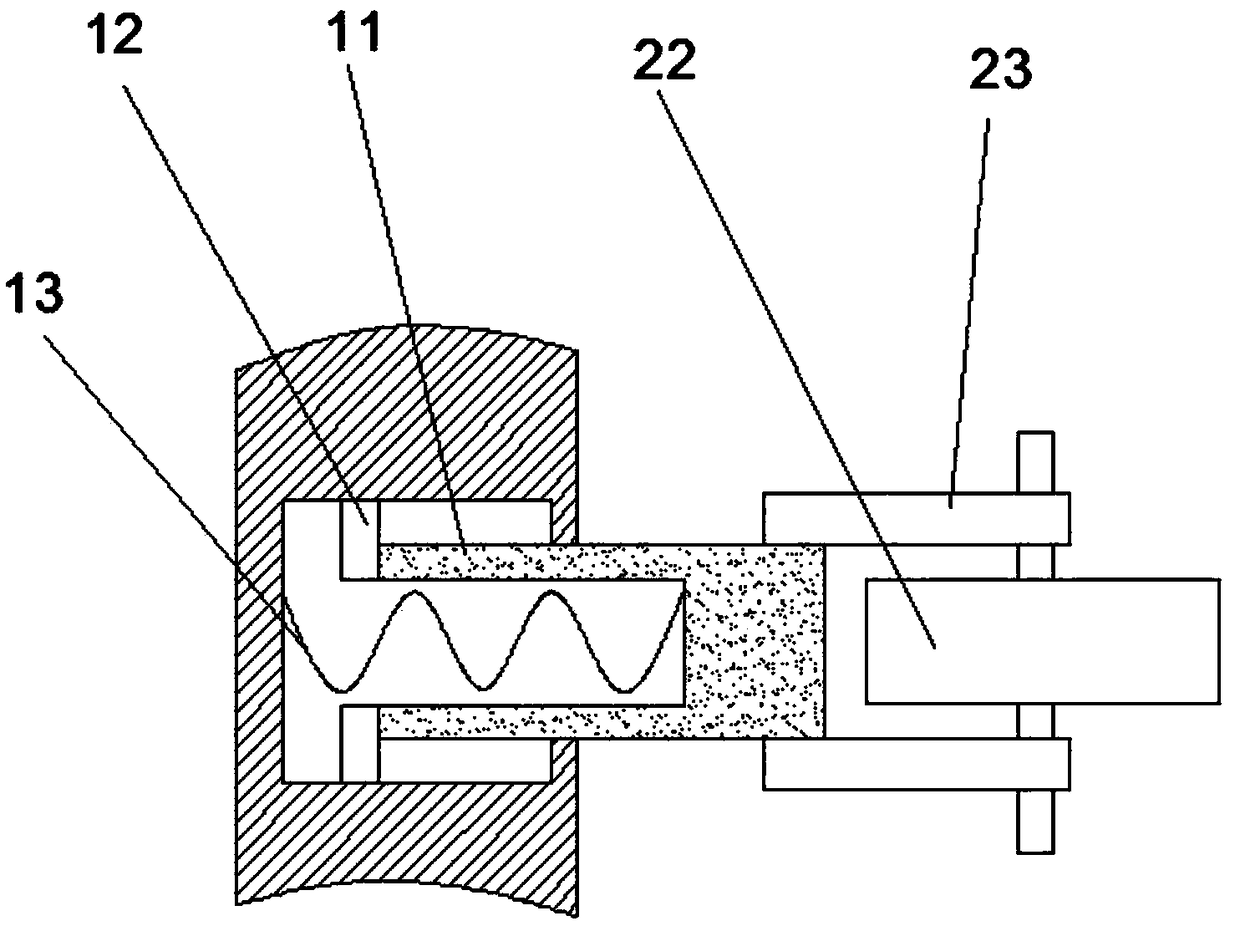

[0020] Such as Figure 1-Figure 3 As shown, a tensile and flame-retardant silicone rubber cable proposed by the present invention includes an outer waterproof layer 1, a middle insulating layer 2 is arranged in the outer waterproof layer 1, a connecting layer 3 is arranged in the middle insulating layer 2, and the connecting layer 3 An internal main frame body 5 is arranged inside, and sliding hoses 6 are provided at four fixed angles of the internal main frame body 5. A strut 7 is arranged in the middle of the upper and lower ends of the internal main frame body 5, and one end of the inner side of the strut 7 is provided with a Some connecting plates 8, the upper and lower ends of the inner main frame body are all provided with some vertical plates 9 outside the poles 7, and telescopic springs 10 are arranged between some connecting plates 8 and the inner main frame body 5, and one end of the outer sides of the poles 7 A first wheel frame 20 is provided, and vertical wheels 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com