A special lift device for a paint cylinder

A lifting device and paint vat technology, applied to the device for coating liquid on the surface, insulating conductors/cables, electrical components, etc., can solve problems such as low work efficiency, troublesome, inconvenient disassembly and assembly, and achieve high quality, Scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in combination with specific embodiments.

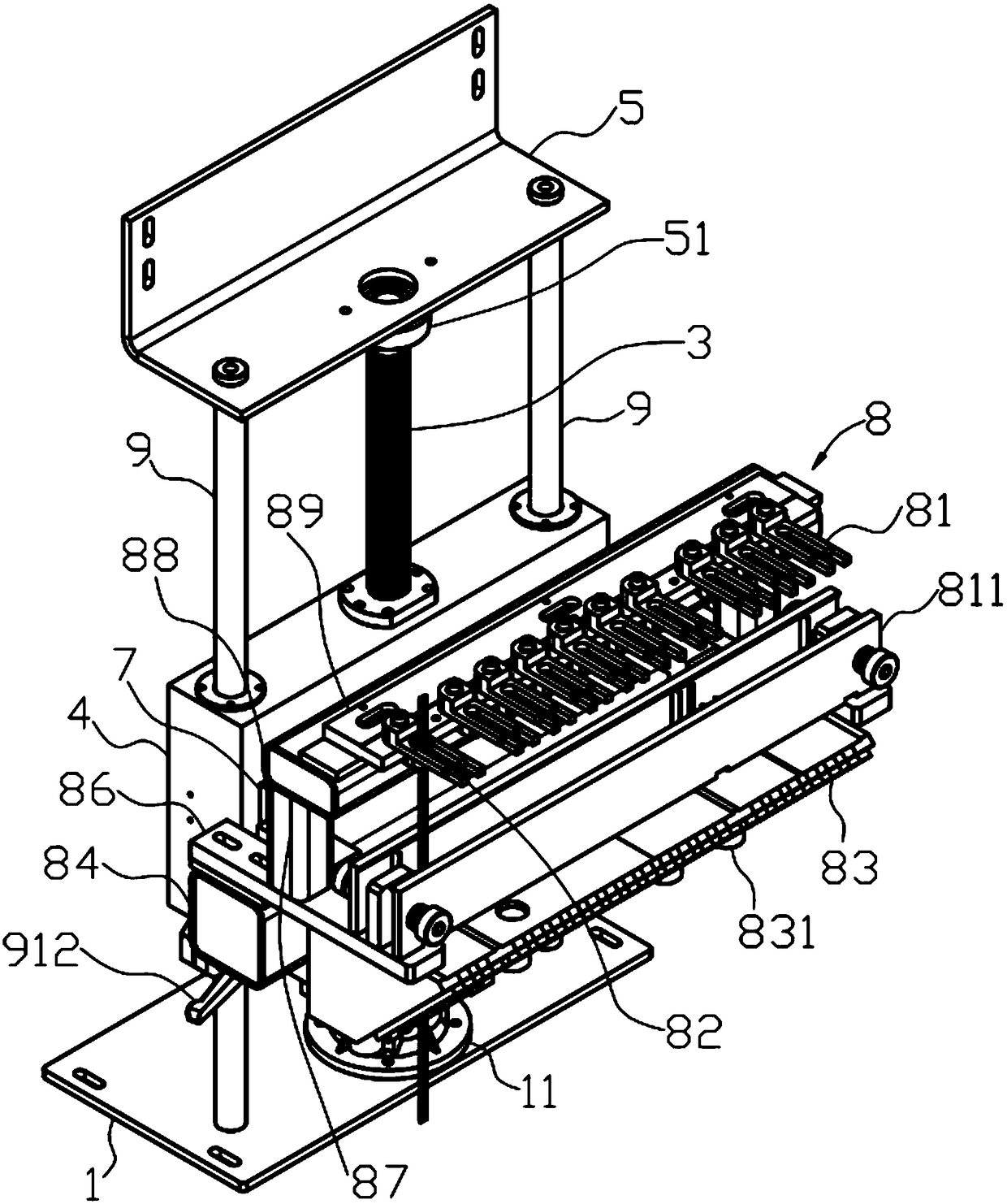

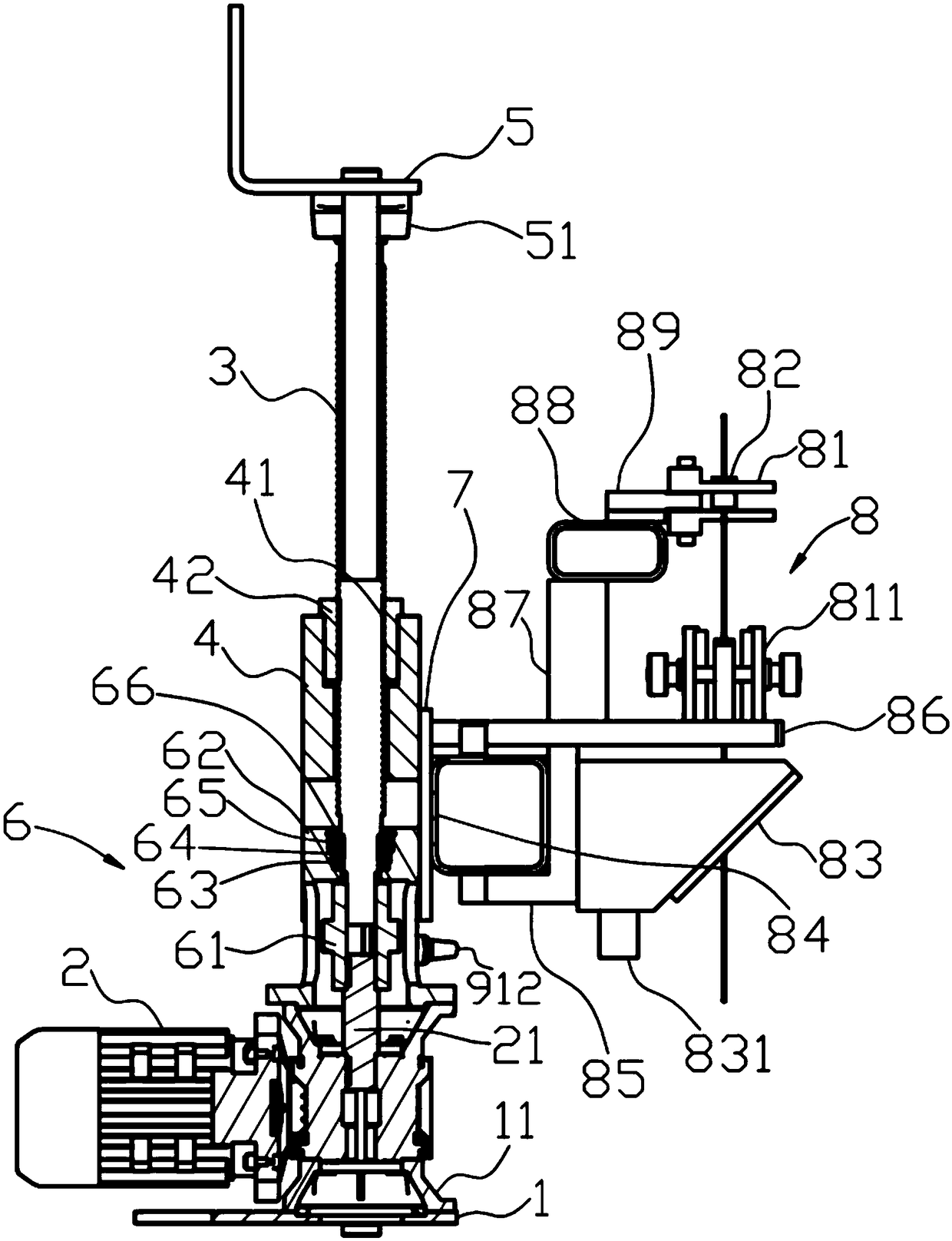

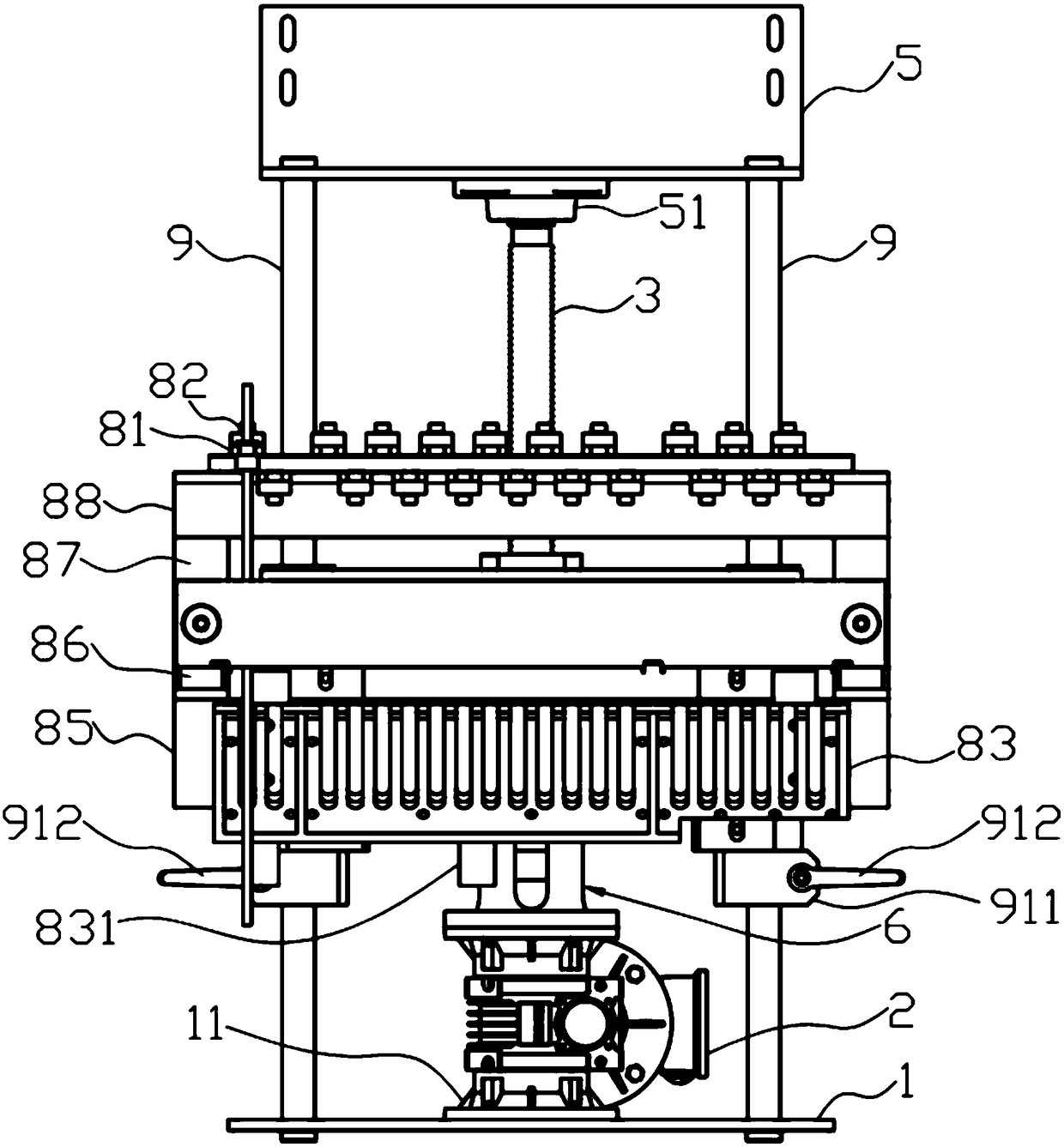

[0017] Such as figure 1 and 2 As shown, a special elevating device for paint vats according to an embodiment of the present invention includes a motor plate 1 , a worm gear motor 2 , a ball screw 3 , a guide body 4 and a top plate 5 . The worm gear motor 2 is fixed on the motor plate 1 through the flange 11, and the worm 21 of the worm gear motor 2 is vertically upward to the motor plate 1 in a vertical shape. The ball screw 3 runs through the middle of the guide body 4, and the guide body 4 is provided with an internal thread 41 that cooperates with the ball screw 3. The bottom of the ball screw 3 is connected to the worm 21 of the worm gear reducer motor 2 through the coupling 6. The top of the ball screw 3 is connected to the top plate 5 through the first bearing 51 . The side wall of the guide body 4 is connected with a paint bowl device 8 through a vertical side pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com